-

Posts

7054 -

Joined

-

Last visited

-

Days Won

148 -

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Adolf Hamster

-

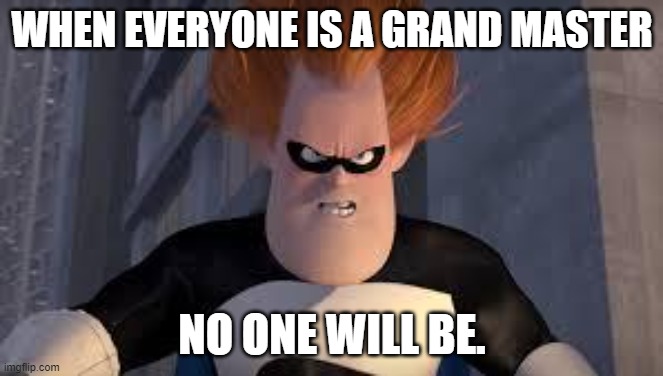

i see the profile badges have been updated....

- Show previous comments 2 more

-

-

@Rogerborg i've heard tis a popular hobby

-

After years teching rifs in the mountains of Shaolin, the rank of master is achieved.

-

- Paul72 and Adolf Hamster

-

1

1

-

1

1