Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

-

Posts

7038 -

Joined

-

Last visited

-

Days Won

148 -

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Adolf Hamster

-

Help! Cracked G&G gearbox V2 with blowback

Adolf Hamster replied to Daddy Foote's topic in Electric Guns

personally, i'd be going with option 3. @Speedbird_666's link has shells in stock. ofc wether or not you want to fix up to use or fix up to sell is down to you. cylinders and pistons can be found here, along with other parts: https://www.ak2m4.co.uk the steel rack pistons you'll want to glue the rack in place before final assembly (they're removable in case folk want to do any tooth shaving shenanigans). if you're replacing the cylinder (and de-activating the blowback), the fps might jump up as a result, so be mindful a spring change might also be on the cards. -

didn't think about that one. i normally do a mid-way of having option 1 with the loop going under the second peg on the trolley or at least whichever method has the spring sitting straightest. your right that the COL doesn't look significantly worn, the gears definitely not worn either. not really seeing anything jumping out to eye, perhaps the col edge could be closer to the sector gear but again if that's the original col and gears then that's where it's supposed to be, but then we are talking airsoft levels of precision. you could try pulling the trigger pack, have just the sector and col in and rotate it to see what kind of range of motion it has. yeah that's the gap i'm thinking about. if it were me i'd rather be checking different col's until finding one that was naturally a bit higher in that regard, main downside is getting access to a bunch of different col's. when i did it would go to the local shop, tech there didn't mind me having a rummage through and chucking him a couple of £ for whatever random part i'd found to do the job.

-

that's a pretty common issue with a non-matched col. part of the whole "compatible-ish" nature of airsoft. sometimes it's a case of try a bunch until you find one that works nice and why a well stocked box o' bits is handy. did the original look particularly worn? yeah it's a steep curve but does get easier.

-

binary triggers i can sort of get behind as they effectively remove semi. sure you could fire one round then release the trigger pointing at the dirt, but lets face it nobody is gonna do that making 2 rounds the de-facto minimum you're gonna be sending at a target. sure you can get a reasonably high round count with regular spamming, but however fast you can spam on a regular trigger is doubled on a binary trigger. box mags on pistols i'm not so sure on, certainly for certain themed events i get it but for regular skirmishing? can't say i agree. sure i hate em, but you just gotta accept some folks don't think that way, and i can't really see them as being particularly enabling of dickish behavior in the same way binary triggers are (as in, what can you do with an m4 mag hpa'd hicapa that you couldn't do with an hpa'd arp9?) the 2-tone thing i don't get at all, so some people are impatient and don't want to wait to get registered? what's wrong with that? again for themed events maybe, but not regular skirmishing.

-

don't blame ye, 90% of the firing i did with mine was in bursts outdoors, admittedly i lean towards semi in other guns, where the trigger isn't made by black and decker..... it's one of the issues with the more obscure platforms is getting weird niggles like this, if it's any consolation the original g&g was every bit as bad but throw in lack of available spares for the trigger/col and lacking the end-game option. unlikely, out of the 2 the col is the thing that'll wear. don't think i've ever seen a sector cam actually wear out (as opposed to the default shape not matching a given col for a given box)

-

11mm Dovetail scope mount for AK-74.

Adolf Hamster replied to Sifu Steve's topic in Guns, Gear & Loadouts

tbh i don't think search terms are the issue as much as i don't think there'd be many options to begin with. at least as a pre-made unit. the systems like the ones you linked have the rail just screwed on, easily removed and you could fit some 11mm rail by tapping it onto the base which usually is chunky enough (by airsoft standards). i had a night vision scope was mounted that way (albeit bolted direct to the scope and with intense paranoia about the mount being too weak to hold what was a monstrous optic) -

that was my initial feeling, but the issue is that whereas in a normal gun the COL gets lifted free when used in auto that's not happening. although i've had plenty of v3 boxes firing a lot of rounds in semi auto to suggest they shouldn't wear out that quickly. the thing i'm thinking is it's essentially half-pulling the trigger in normal use, compared to how it'd be in its normal ak role which is what the trigger/trolley/col was originally designed around. i must admit, i'm getting a lot of deja vu here. col's wearing out quicker than you'd expect (granted on the g&g it's as much due to the weird leverage it's being put through) and being just a bit finnicky on semi. fingers crossed, if not there are still some cards left to play. is an interesting solution, but it's for the g&g non mosfet version, although granted i wish it had been a thing when i was going through this

-

hmm, that's very definitely the col failing to lift the trolley. wonder is the col worn? i know i said i didn't think it had earlier but i'm starting to doubt myself on that front. looks like it's in constant engagement, usually when you fire in auto it's lifted out of engagement to stop it wearing out as quickly. other thing might be worth trying, but if you remove the auto contacts (as in physically remove them, not just isolate the wiring) and see if the extra clearance to pull the trigger back lets it trip properly?

-

Macks airsoft dreamers of the week thread

Adolf Hamster replied to Mack's topic in General Discussion

i mean compared to what some people do to ak stocks, some filthy, heretical people..... -

hmm, i thought you could turn it off on the merf, compared to say the nanoaab (picoaab? something like that) where it's permanent. that could well be a potential candidate then, i certainly wouldn't be ruling it out as causing this as i've seen more than enough guns go from chugging all day long to barely scrape a few shots thanks to ab. pinching this pic from earlier in the thread: the trigger will push the trolley forwards, the col kicks it up, the return spring pulls it backwards over the top of the trigger (well, the trigger extension) until it's reset. come to think of it, looking at that picture, is that spring (the one just above the arrow tip) getting pinched? kinda looks it? that should be the spring that pulls the trolley back. that shouldn't be affecting it as long as it's able to do a complete cycle. only real issues you'd see is either the wrong type or worn out col (unlikely in this case- i'm assuming those are original parts and not that old) or the sector gear shimmed way too high (again unlikely, it's pretty tricky to go that extreme)

-

so it's still firing bursts on semi? the mosfet should only run while it's getting continuity between the 2 signal wires, it relies on the gun to shut off. if it keeps getting signal it thinks it's just being run in auto. the paper will prevent the auto contacts from triggering, which is easy to accidentally trip when testing on the bench (the g&g v6 has the same issue, albeit with the "trigger" being mounted in a different place) so the gun isn't shutting off, one thing to check- do you have ab enabled? if you do try turning it off as that can cause some weird issues (took me years to figure out thats what the issue with mine was). the other thing, which is what you've been looking at, is that the contacts don't engage too early, in a position where the COL isn't able to trip them when it fires. do you need it semi only for DMR power? if so then one way would be to remove the connection to the auto contacts

-

Help! Cracked G&G gearbox V2 with blowback

Adolf Hamster replied to Daddy Foote's topic in Electric Guns

You can cutoff the vent hole by replacing the cylinder for one without the matching hole, the hole in the gearbox shell would then be redundant. Iirc you have to remove the rubber gasket as well but the rest of the blowback components you fit normally. It'd still be a weak point for a future crack though -

generally i tend to suggest cleaning the barrel before every outing, it might be dirty, it might not, but if you clean it before every game then it definitely won't be dirty. it's not particularly time consuming or difficult and it's amazing how much performance can be lost through lack of cleaning. suggesting upgrades is a very personal thing as it'll depend a lot on what particular area of performance you want to improve, and how far you want to go in improving it. so the general advice is leave it alone, go and play a few games, then start thinking "what is my gun not doing well enough for me?", followed up by "how much better will i be happy with?", then you can come back with a more specific question and we can advise on what areas you'd want to look at to address that issue. you'll also get a good feel on how well the gun performs so when you start tinkering you have an idea whether or not the work you've done has actually made the gun any better, because that's not necessarily a guarantee.

-

Help! Cracked G&G gearbox V2 with blowback

Adolf Hamster replied to Daddy Foote's topic in Electric Guns

hmm, that's the pneumatic blowback system. the tricky thing is if you replace the gearbox shell for a standard shell there won't be any accommodation for the blowback components, so the interface for your charging handle and mock bolt cover possibly won't fit. i've worked on the m4 variant of this box and i'll be honest i'm not a fan of that system, the blowback is a horrendous source of air leaks giving inconsistent performance. if it weren't cracked i'd be suggesting to de-activate it, which is fortunately not too complex you just replace the stock cylinder for one without the vent hole at the top, it'll lose the blowback but gain shot-shot consistency (aka accuracy), although you might need to drop the spring as the existing one will be slightly stronger than normal to account for the air used for the blowback. if you can find that same type of shell, then that might be the easiest option, do the above de-activation of the blowback and run a lighter spring (will lessen the load on the casing making it less likely to crack again) whilst still allowing you to have the blowback cylinder in-place so it can interface with the charging handle/bolt cover. otherwise you might have to leave the bolt cover out, which is fine as it's just cosmetic but it won't look nice having the hop unit always on display. there's also the issue that another box might not quite line up right in the reciever/be subtly different and cause issues. in terms of the gearbox internals, i'm wondering if what's happened is the system has somehow stopped just before release, then the motor hasn't had the torque to get it moving again when it's trying to start under full load. hard to tell from the description if the piston/gears need changing or not, some pics might be helpful? in terms of mosfets then it's a case of what sort of functionality do you want? is it just saving the trigger contacts from burning out or do you want fancy shenanigans like precocking as well? -

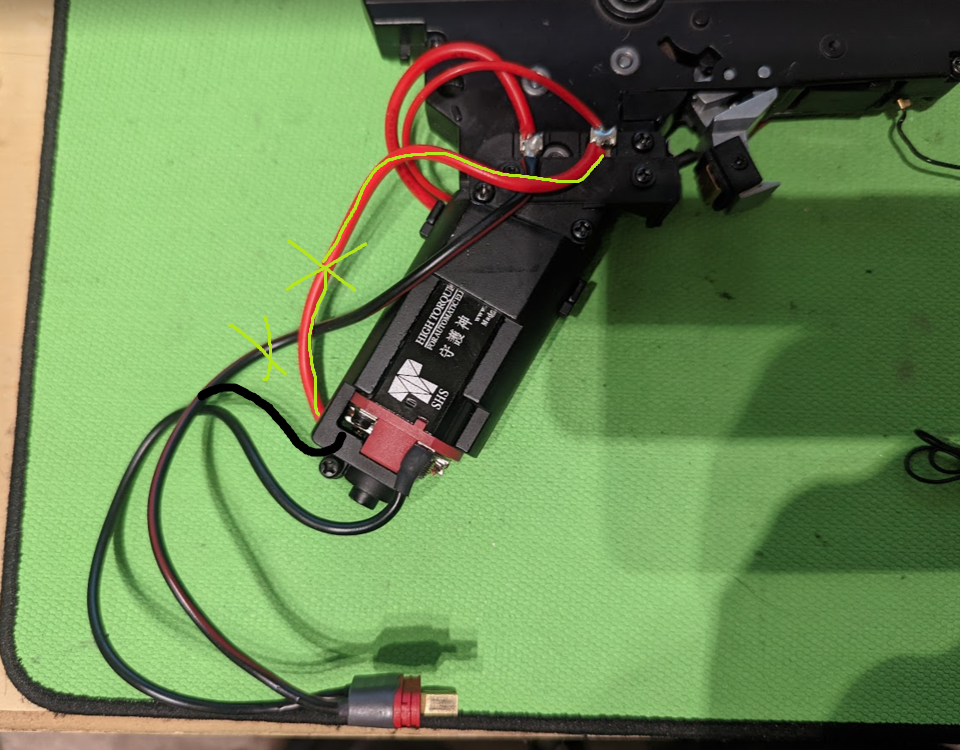

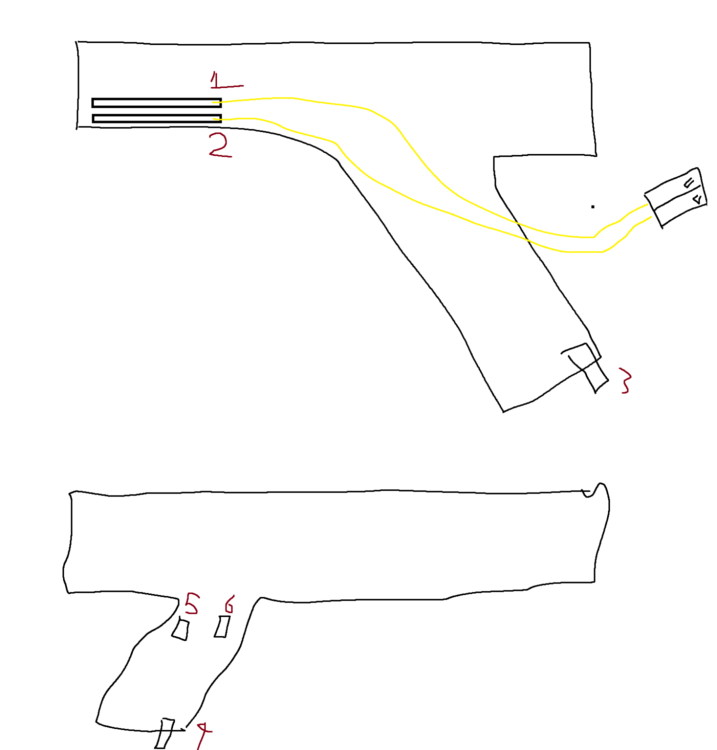

the light wire is fine for the majority of the wiring going from the mosfet and across the 2 sets of contacts. you'd only need enough heavy gauge wire to go from the motor to wherever the mosfet is going to be, for example the one terminal already going to the deans connector from the motor won't need touched, just trim the other wire coming from that deans and plug it straight into the motor. something like this: remove the green-traced wire entirely, cut the black striped wire where the green X is and solder it (black line) to the motor spade (or the the motor, if you feel so inclined) your other 2 red wires you could leave as-is, personally i'd swap them for the light-gauge wire for the sake of neatness but that's up to you. edit: some top tier mspaint skills later: so wiring wise: 1 has light wire going to the smaller mosfet connector, and to point 5 (which one doesn't matter) 2 has light wire going to the smaller mosfet connector and to point 6 (which one doesn't matter, as long as it's not connected to 1 or 5) points 3&4 are wired with heavy wire to the mosfet deans connector (with polarity matched for the right motor direction), like the above pic.

-

personally, i'd go with the 2-wire setup. iirc they give you plenty of wire with the 2 sets of connectors, enough to trim a length off to bridge the semi and auto connectors (if not, lemme know, mans probably has some lying around somewhere) then run the heavy gauge direct from the mosfet to the motor (only place it's needed), basically the 2 motor spades going into the same deans plug which then goes to the mosfet.

-

it's possible @Iceni's theory about the wiring being off is maybe happening. normally with the gate mosfets i find it much easier to use the 2-wire setup (as in @Iceni's drawing) than try and muddle through the single wire setup, although bearing in mind the pic is the g&g v6 box rather than the cyma v3, but the same general idea just the contacts are in different locations.

-

Suggestions for metal old school AK, for paint project

Adolf Hamster replied to Sifu Steve's topic in Guns, Gear & Loadouts

As above- cyma are pretty much the baseline of solid all-rounder, e&l are more expensive but have prettier externals which will rust. Either are good choices, depending on your budget and wether you like a heavy gun or a light gun. The jg's arent bad shooters with a bit of tinkering, although the term "blowback" is a bit of a stretch, whilst the system is somewhat fragile it's also relatively easily deactivated and it'll run as a regular aeg. Ran one for years as my backup/loaner gun and it was genuinely a fun little shooter that i'd often run just for the hell of it. -

WE TT-33 or SRC SR33 Threading of the barrel?

Adolf Hamster replied to parallel-knight's topic in General Help

Never actually broke a loading nozzle on the makarov, admittedly i bulged one but that was definately qc failure and nothing to do with it being fed .48's...... -

precocking is like a timer that runs after the col has tripped and keeps the motor running a few milliseconds before (usually) applying active brake. usually lockups with active brake are the product of a system that doesn't need it stopping too quickly when the brake is applied (ie col trips and it stops immediately), without active brake the motor naturally rolls on for a little bit of precocking (ie how guns without mosfets work) until natural friction/energy compressing the spring is enough to halt it. i suppose if the precocking is set too high it might be rolling right around and approaching that lockup point from the other side (although would probably be intermittent double firing too)

-

WE TT-33 or SRC SR33 Threading of the barrel?

Adolf Hamster replied to parallel-knight's topic in General Help

I dunno, the we makarov is pretty decent once you get the hop sorted, although granted not a strong cold weather performer.