-

Posts

4,894 -

Joined

-

Last visited

-

Days Won

76 -

Feedback

0%

Sitting Duck last won the day on December 28 2020

Sitting Duck had the most liked content!

Profile Information

-

Gender

Male

Recent Profile Visitors

47,396 profile views

Sitting Duck's Achievements

-

SSPKali reacted to a post in a topic:

Some easy simple Airsoft Maths that I think work

SSPKali reacted to a post in a topic:

Some easy simple Airsoft Maths that I think work

-

Zarrin reacted to a post in a topic:

Tell Us a Gag. Please!

Zarrin reacted to a post in a topic:

Tell Us a Gag. Please!

-

Sebza reacted to a post in a topic:

Tell Us a Gag. Please!

Sebza reacted to a post in a topic:

Tell Us a Gag. Please!

-

Paul72 reacted to a post in a topic:

Memes to chill the f#ck out

Paul72 reacted to a post in a topic:

Memes to chill the f#ck out

-

Spacemonkey reacted to a post in a topic:

Pinion to Bevel Shimming

Spacemonkey reacted to a post in a topic:

Pinion to Bevel Shimming

-

EDcase reacted to a post in a topic:

Tell Us a Gag. Please!

EDcase reacted to a post in a topic:

Tell Us a Gag. Please!

-

Shamal reacted to a post in a topic:

Tell Us a Gag. Please!

Shamal reacted to a post in a topic:

Tell Us a Gag. Please!

-

Tackle reacted to a post in a topic:

Tell Us a Gag. Please!

Tackle reacted to a post in a topic:

Tell Us a Gag. Please!

-

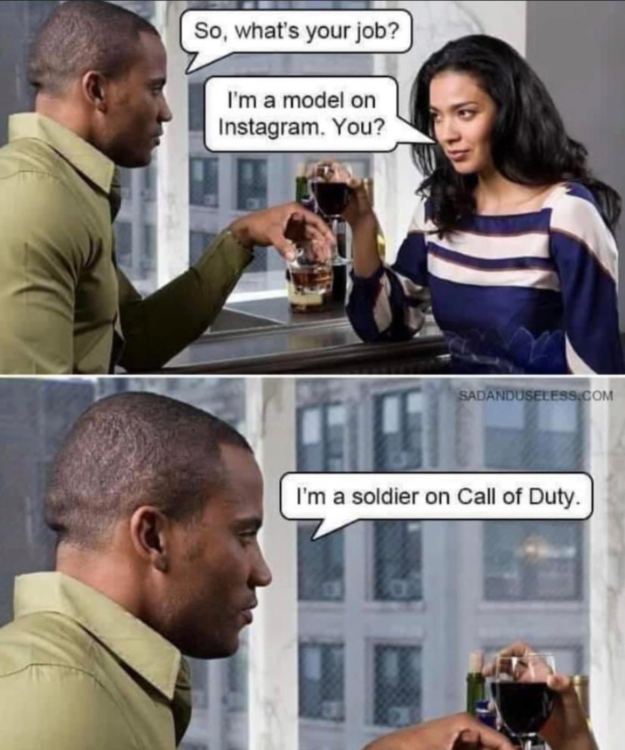

not quite a joke but I found it funny all the same & the guy's response is sort peew peew related...

-

Sitting Duck reacted to a status update:

New Perun Hybrid installed. Anti retard design: you REALLY need to be special to mess

Sitting Duck reacted to a status update:

New Perun Hybrid installed. Anti retard design: you REALLY need to be special to mess

-

JamesAirsofterAgent reacted to a reply to a status update:

Well... I just found out as a suprise bbirthday present my dad ordered an airsoft pis

JamesAirsofterAgent reacted to a reply to a status update:

Well... I just found out as a suprise bbirthday present my dad ordered an airsoft pis

-

Sitting Duck reacted to a reply to a status update:

Coming to terms now with being diagnosed T1 Diabetic out of the blue. Gives me someth

Sitting Duck reacted to a reply to a status update:

Coming to terms now with being diagnosed T1 Diabetic out of the blue. Gives me someth

-

Sitting Duck reacted to a post in a topic:

What Helps You Decide on a Magazine?

Sitting Duck reacted to a post in a topic:

What Helps You Decide on a Magazine?

-

What Helps You Decide on a Magazine? Readers Wives ??? (edit my bad wrong forum)

-

Sitting Duck reacted to a reply to a status update:

PUBS ARE OPEN funny...

Sitting Duck reacted to a reply to a status update:

PUBS ARE OPEN funny...

-

PUBS ARE OPEN funny...

-

The 'What have you just bought' Thread

Sitting Duck replied to Cameron364's topic in Guns, Gear & Loadouts

CQB with all that - don't need that on a CQB gun you need... kidding/sarcasm btw... as said I'm more minimalist approach though a flashlight for dark CQB would be one of my add-on's I guess -

The 'What have you just bought' Thread

Sitting Duck replied to Cameron364's topic in Guns, Gear & Loadouts

Two scopes/red dot sights ??? reminds me of... to each their own, I like FH's too but as is, minimal look with a stubby stock etc... (buffer tube battery idea was not a great idea imho but ho hum & all that) -

Sitting Duck reacted to a post in a topic:

Hobbyking Bb's. Anyone Tried Them?

Sitting Duck reacted to a post in a topic:

Hobbyking Bb's. Anyone Tried Them?

-

If it's global - aka Hong Kong then the issue will be shipping & customs as per usual found some more local biodegradable ones if you are interested in saving money... https://www.realplasticfree.com/product/25274/organic-green-peas?PackID=24038 100% plastic free...

-

Sitting Duck reacted to a post in a topic:

£109m on the Euromillions Tonight - What's Your First Airsoft Purchase

Sitting Duck reacted to a post in a topic:

£109m on the Euromillions Tonight - What's Your First Airsoft Purchase

-

A JOKE but if this truly offends then mods please remove A Jewish/Scottish/extremely careful with his money (delete as required) man goes into the synagogue/church/place of worship (again delete what offends) and prays. "O Lord, you know the mess I'm in, please let me win the lottery." The next week, he's back again, and this time he's complaining... O Lord, didn't you hear my prayer last week? I'll lose everything I hold dear unless I win the lottery." The third week, he comes back to the synagogue/church/place of worship (again delete what offends), and this time he's really desperate. "O Lord, this is the third time I've prayed to you to let me win the lottery! I ask and I plead and still you don't help me!" Suddenly a booming voice sounds from heaven... "Benny, Benny, be reasonable. Meet me half way. Buy a lottery ticket!" sorry if this offends but I think it is a little amusing I've given options and if somebody is still offended ah bollocks, lighten up

-

Home Build M4 Overheating Batteries - Help/Advice Welcome

Sitting Duck replied to Caber77's topic in Electric Guns

Guarder SP110 = M120 Spring, so potential 394fps ??? 47rps ??? I could see you clipping near 27rps on 7.4v, then maybe 41rps on 11.1v - but 47 is going some, Though a beefy C LiPo will give you extra zest, The flip side is the fancy ETU's tend to skim a bit of power, (each diode nicks 0.5-0.7v, turn on/forward voltage). 30k ÷ 12.75 (ratio) will give you about 23.5rps, Squeeze a bit more out on 16awg/deans, shim well about 27rps, x 1.55 = maybe 42rps & I've smashed a piston at that speed even though it was short stroked 3 teeth ??? So 47rps is going some, perhaps questionable, given that ETU's skim some juice & motors should make a difference... A 30k motor Vs a 18k G&G there will be a difference. Also forget bells & whistles a second... Set the Titan to do basic stuff, no AB, precock, burst etc... Grab a standard RC power meter, Plug that in and run a 5sec auto burst on 7.4v, NB 7.4v not 11.1v to check amps on meter in auto, coz the way the fancy MOSFETs report stuff varies. Yes the surge from still will be 80-90 amps, But overall the draw over a 5 sec period should, be below 20, about 17 amp if done well 12:1 30k. Draw will be lower on higher TPA motor, But G&G 18k grey will struggle on 7.4v as it's ferrite. The amp draw on 7.4v will be roughly the same as 11 1v, The amps don't change, but the wattage alters on 11.1v, Watts = Voltage X Amps All you are doing is testing the amps on a meter, without risking smashing the piston at silly speed, Or excess heat being generated on a high amperage. Get the amps read from a meter on a 4-5 sec auto burst, Ensure it is below 20amps on a meter reading. Is the sector/gun short stroked ??? Coz SP110 spring is near 400fps Yes you lose a bit on a 300mm barrel, But think you are losing some FPS somewhere too, Coz the gun is losing efficiency it is working more, on the SP110 or M120 spring unless SS'd 2-3 teeth. And if running inefficiently that 47rps is dubious, Unless motor is a High Speed one, Which would explain it a bit along with heat/amps... A number of things don't quite add up to me, The slightly higher rof on a higher spring, Lots of heat & killing batteries etc... Motors not making much of a difference ??? (They should as you have a range of performance) Yeah some stuff ain't quite as it seems to me, So check the amps on a RC power meter/analyser... Seems like you have used a SHS lightened piston, so I wonder if the piston is binding quite a bit... Which would explain some things, heat, amps, some power loss... Yet this would effect the rps, which is quite high still... So yeah, some things are not quite adding up to me ??? -

Sitting Duck reacted to a reply to a status update:

ok ak47 qustion time lol not bothered about the style of ak as i pretty much like the

Sitting Duck reacted to a reply to a status update:

ok ak47 qustion time lol not bothered about the style of ak as i pretty much like the

-

Sitting Duck reacted to a post in a topic:

Cyma Cm.621 Upgrades

Sitting Duck reacted to a post in a topic:

Cyma Cm.621 Upgrades

-

jeeez my neck hurts looking at Australian builds... (rotate pic next time - pretty please) niiiiiiiccceeeeee btw

-

Great - it's bad enough getting people to chrono their guns in time to play Now we will have teenagers/players whinging they can't get a decent signal so can't head out just yet - gimme a sec, nearly got 1 bar, whoa 4G too.. Oh shit, it's gone again... hasn't this woodland site got free WiFi or can we not play with better coverage meanwhile - SHIT we've been EMP'd or they got a counter UAV... Nope the owner is jamming the mobile signals coz he is getting fucked off with mobile muppets piss balling about and holding up next game nah - COD/Fortnite is one thing & peew peew is another

-

Sitting Duck reacted to a reply to a status update:

seeing alot more people mentioning swiss cheese pistons what is the point in them oth

Sitting Duck reacted to a reply to a status update:

seeing alot more people mentioning swiss cheese pistons what is the point in them oth

-

Sitting Duck reacted to a reply to a status update:

seeing alot more people mentioning swiss cheese pistons what is the point in them oth

Sitting Duck reacted to a reply to a status update:

seeing alot more people mentioning swiss cheese pistons what is the point in them oth

-

Like everything I guess... TV's £300 no longer buys you a big ye olde box TV it no longer buys you a chunky flat screen but now a wafer thin 50" mofo HD with 4k option a little bit more Sure they aren't Sony, LG's etc... but fuck me they are not that far behind £60 ~ £70 guns are ergh £60 ~ £70 guns still but point being the guns now at whatever price tag have improved loads and like TV's and shit you are getting a lot more better value for money Cheap or cost effective TV's or Cyma's or whatever have made others up their game Some of the slightly better Cyma's like Hi-Speed versions with 13:1's and say a 22tpa with a basic mosfet for say £35 more than a basic model represents good value for money as it would cost you that anyway (so some thought went into these gun model options) Can't comment on the more higher end metal M4's, but expect same applies I rated D-Boys which are Double Bell 416's a few years ago though at the time the hop was shit clear plastic and they have also made some improvements and unless you are trademark fan boy, then the D-Boys/Double Bell 416 is a nice cost effective gun (quite heavy as I own mostly cheapo light plastic guns - it is solid weighty 416 without trades) Double Eagle 904G's they are flogging that at fuck all mark up to make in roads and shift stuff in bulk to make money - £100 Honey Badger with basic bells & whistles fuck me, how many of those are gonna show up on game days after lockdown but most stuff & makes have upped their game from a few years ago you are getting more bang for your buck (or more higher res pixels for ya dosh) Cyma have just continually upped their game and most importantly sensibly upped their game making steady improvements bit by bit to result in a lot of decent sturdy cost effective guns for various budgets But be careful trying to contact Cyma's customer service department as this is how the conversation might go... Kidding btw - but still fucking funny

-

worn Cut Off Lever or stick trigger switch/trolley getting stuck in contacts ??? or we talking DSG HC05 or something daft or we are talking about std FH and if so it might have the 8 tooth bevel in it (they also do a 9 tooth bevel as well as the regular 10 tooth bevel) 8 tooth 9 tooth 10 tooth weird eh ??? Sure when I opened up a reg FH it was an 8 tooth in there so it pulled spring easier but gave the ratio 22.38:1 than 18.65:1 hence some launch TT FH's were pretty snappy & others were not, most of them perhaps (grip is one give away, not always though, plus TT sticker in magwell) so was a bit lamer on a 7.4v than the Top Tech ones But even on a 11.1v you'd struggle to hit over 20rps on a modest FH and you can't fit much of a 11.1v in the stock tube so can't see the absolute need for AB myself

-

The 'What have you just bought' Thread

Sitting Duck replied to Cameron364's topic in Guns, Gear & Loadouts

issue if the nozzle is tooooooo long, then even on full retraction there isn't say nearly 7mm in font of nozzle in hop unit to chamber/allow a bb to slip/pass & into bucking if the nozzle is tooooooooo short it feeds better, but shorter nozzle never quite seals on bucking resulting in fps loss as lips blow from lighter sealing pressure it will probably be fine with a small tiny tolerance - you get a bit of give n take if you get feed issues then you may have to fit delay clip or file nozzle lightly you might be OK on semi or slower speeds, on faster snappier guns feed issues can occur more sometimes you got a bit of leeway & others you have finer tolerance or tappet/nozzle window (don't worry about it - I over think shit way way way too much) give it a go and suck it & see as the saying goes, you'll probably be OK if not start a new thread for more of your toy gun headaches -

The 'What have you just bought' Thread

Sitting Duck replied to Cameron364's topic in Guns, Gear & Loadouts

Cool - no wobbly nozzle then ??? coz the SHS ones I have - from Gunfire & decent Chinese sellers were a bit loose (snug in other tappets like SHS ones, but was loose in Cyma clear & recent blue tappets) had some snide lighter red/pink nozzles that were shorter & fit poorly in every tappet mind you the nozzles i got are a few years old I guess, even the SHS ones so if Pete's nozzles fit snuggly I'd be interested in grabbing a few myself POM nozzles that are too tight fit can distort if wedged into a tappet & lose good seal at o-ring it is the classic pita compatible crap - often stuff works alright but other times they don't go to plan (like the larger eyelet on Cyma switches, v3 spring guide in v2's, ultra loose as fuck cylinder head odd safety arm screw outside box, different tappet plate, possible qwirky nozzle, reinforced box for 13:1's piston head is alright once you change o-ring though) cheers for heads up - might drop Pete a line re nozzles 21.4mm ish, it is in Luke's recent video but knew that anyway - it is around 21.4~21.45 (common M4 nozzle, some use nozzles a little shorter like ICS & some others) in some boxes/builds it can a whisker too long hence measure nozzle and other stuff to compare it all but yeah Cyma's are usual 21.4mm -

well then it is "something" you have done with all the experimentation (pretty obvious - but if all back to stock & still shit then something has taken place) Only you know what you have done, likely the shimming/height is not the same as it was The only other thing I can think of is something else you altered/changed (& not mentioned) eg: new piston that is ultra fucking tight binding, causing extra drag/load (way more than a smidge higher spring)