-

Posts

1719 -

Joined

-

Last visited

-

Days Won

30 -

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Speedbird_666

-

The Most Boring Noob Question - Knee Pads?

Speedbird_666 replied to 38super's topic in Guns, Gear & Loadouts

Are those AltaContours? I think it can be agreed that Alta makes really good products. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Took me a full 5 seconds to work out what you were on about until I spotted the Haribo. ? If you don't like the stock, I'll have it off you if you choose to sell it.....? -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

I didn't frequent these forums much at the point when things kicked off with him, but I've heard he's quite a character. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Your picture's dead - what did you buy? -

The Most Boring Noob Question - Knee Pads?

Speedbird_666 replied to 38super's topic in Guns, Gear & Loadouts

I think @Tacklenailed it with his idea. Four of these ITW Nexus Square loops sewn onto the outside of the trousers for each leg (two a side). Pass the knee pad strap through them, means no way to slide down. Clever and very cheap if you are handy with a sewing machine. -

The Most Boring Noob Question - Knee Pads?

Speedbird_666 replied to 38super's topic in Guns, Gear & Loadouts

Yep. And Viper Elites Gen 2s can be had for £55 here. -

The Most Boring Noob Question - Knee Pads?

Speedbird_666 replied to 38super's topic in Guns, Gear & Loadouts

Viper is hardly pricey, it's very much at the lower end of the price scale for those style of trousers, although the quality is reasonable for the money paid. Good enough for most people's LARPsoft/BBWarz. -

The Most Boring Noob Question - Knee Pads?

Speedbird_666 replied to 38super's topic in Guns, Gear & Loadouts

Have you tried Altaflex knee pads? I've had good luck with them, and own several (different colour) sets. They're amongst the best I've come across. https://www.military1st.co.uk/ok-afl-cd-34-alta-tactical-altaflex-knee-pads-multicam.html -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

https://www.airsoftzone.co.uk/cnc-metal-hop-up-chamber-and-nozzle-set-for-ak-series-combat-union.html -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

This was must of been a few years ago....what happened? -

Macks airsoft dreamers of the week thread

Speedbird_666 replied to Mack's topic in General Discussion

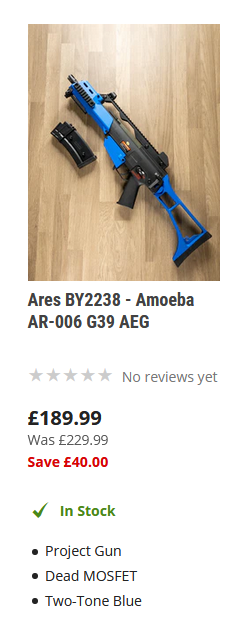

I noticed that - some of the them were only £20 less than retail. Broken or missing bits. Not really any kind of bargain. Case in point: They were selling these new, in black, for £160 in January. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

At the grand old age of 39, yes, I could be your father. You would have been 5 when I started playing Airsoft, and -1 when I started playing Paintball. The reason I mention the Two-tone is because A) only a fucking idiot gets a £350 gun two-toned and B) It shows your inexperience. Please bring us up to date with your real-world airsoft experience that backs up the bollocks you've been coming out with. Apologies, I didn't see this when I made my post -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Not quite how remember it. More like: - Uninformed, low post count noob comes onto the forums with his two-tone 'specialist platform' - Makes comments about barrel length - Told length doesn't matter compared to other factors - Berates the experienced hand on here that have been building guns for years - Spouts off stuff about physics, experiments and 'do some research' - Is also an arrogant tosser about it - Calls everyone old, senile and incoherent Yep, that sums it up. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Any issues with mounting in/on the outer barrel? I know that some E&Ls need new holes drilling to marry up to the front of the GB properly. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

I want one of these, so I'd be very interested to hear how it goes. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

*Sigh* if there is a single factor with inner barrels that determines overall performance, it's not length OR the bore size. It's the quality of the internal finish. You can take a mediocre stock brass barrel, and lap it to a mirror finish. Assuming it's straight and true, it will shoot comparably or better than many aftermarket barrels. Hop units, rubbers and nubs have a much bigger impact on range and accuracy. Edit - Back on topic, I had these arrive today for various projects: -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

That's a well-trodden subject that's been debated many times before. Let's not go into it here shall we? -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Well, this was fun. Haven't had keyboard fisticuffs in a while. We're obviously being trolled now though.... -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

-

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

You did, right here And here Jog on back to Facebook with your two-tone specialised platform. Your 'knowledge' will be invaluable to the knuckle-draggers over there. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Your 'SMG' is exactly the same on the inside as many other guns, irrespective of their length. That's the point. Your gun is not fucking special. Or in any way a 'specialised'. It's a generic M4 that takes SMG mags. That's it. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

Hey man, there are plenty of Facebook groups for you young'uns. I'm sure there are many on there, with their super-duper tupperware death cannons, that gladly agree with you. In the mean time, us old farts, who've dicked around with these things for literally decades, will keep to the belief that barrel length is not the primary factor in range and accuracy. -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

This x1000. A NBB MK23 can out-range many AEGs and exhibit better accuracy whilst doing so - all with a very short inner barrel. Why do you think so many people are strapping 3d printed carbine kits onto them and using them as DMRs? It was proven in paintball many years ago, and also proven in Airsoft a number of times over the years too that longer barrel length =/= better range or accuracy. -

Macks airsoft dreamers of the week thread

Speedbird_666 replied to Mack's topic in General Discussion

+1 for G&G BB's. Used to use them a lot when Z1 (my local) was still on friendly terms with G&G and you could buy them through them. I ordered some sample packs of Valkyrie late last year to test and they seemed good to me. Reviews are also very good. As they are a BB-only company, I'd figure they take quality control seriously. -

Macks airsoft dreamers of the week thread

Speedbird_666 replied to Mack's topic in General Discussion

Sounds like you need to give your mate a good kicking. ? (woohoo, 500th post)