Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

-

Posts

1719 -

Joined

-

Last visited

-

Days Won

30 -

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Speedbird_666

-

Pics or it didn't happen...?

-

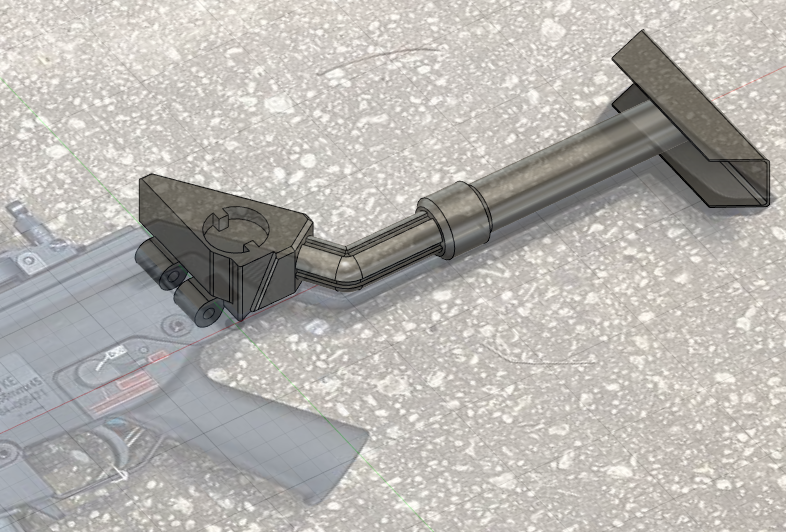

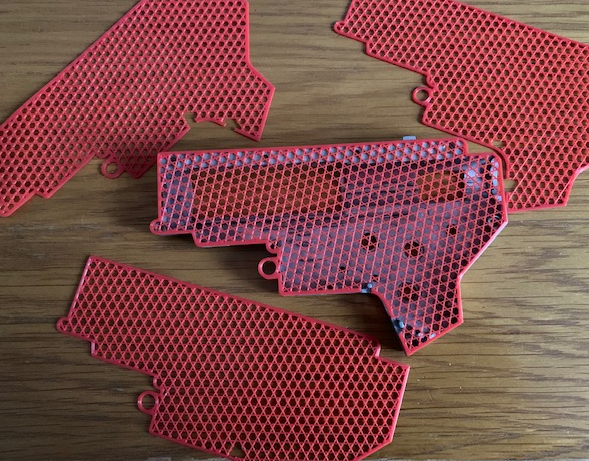

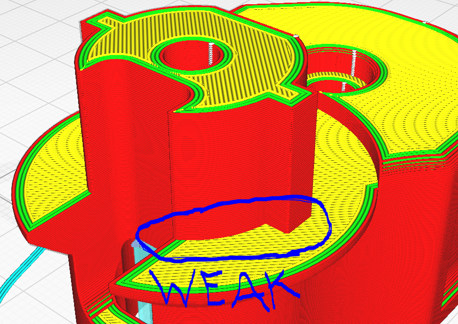

A quick and nasty print to test fitment - 0.30 layer height (accidentally left the upper and lower skin thickness at 0.12 which also doesn't help) and a very low infill leaving a rough finish. Fitment was damned near perfect - just needed the hinge holes opening up a little and a relief hole drilled for the gearbox screw that protrudes a little. Test print was done in two halves then glued - I'm considering creating a channel for a bent steel rod to be sandwiched between the halves for reinforcement before epoxying them together. The final print would be done at 100% infill with a much smaller layer height (around 0.12mm) to smooth things out. Haven't worked out the rear (sliding) bit yet - probably an aluminium tube and 3D printed bushing and stock pad. I'll probably not bother with a sprung button mechanism, rather glue the metal button in place and have it non-folding. Real Steel: Yes, it's ugly. But I like it. Very popular with French and German Police forces - they also use them on MP5s and I've never seen one on an Airsoft gun.

-

Not speedsoft....honestly! I've been modelling a real steel B&T Visor/Gas Mask Stock for a G36 using pictures as a reference. Not sure if I'll actually make this one (although it's dimensionally accurate to TM spec guns), but it's been fun to model nonetheless. RS references:

-

I can't help myself... Ended up with three unique designs for ICS, G&G and Specna Edge guns: Really comfortable with a mask on. I know they look wank, but they are so practical. Much like Crocs or Bum bags.

-

If you don't have much luck finding a replacement part, I could take a crack at knocking something up in CAD that could be 3D printed?

-

Same boat really. Not had any desire to play this year. Tinkering, buying and making (since buying a 3D printer), yes. Hauling my fat arse over to an Airsoft site...nope. It's my two boys (16 and 13) that make me go, and it's fine when I get there and actually play TBH, but I'm the one who preps all their kit, fills their mags, charges their batteries, sets their guns up etc. so it's a triple whammy of ball ache for me when I get to site.

-

I heard the Makarov was shit, but their other offerings are supposed to be reasonable performers from what I heard? At least you can get parts easy enough from Fire-Support. They have their own (TM compatible) Hi-Capa coming out soon that doesn't look too bad at all.

-

Taiwangun Shipping Disruption (Brexit Related Content)

Speedbird_666 replied to Speedbird_666's topic in General Discussion

Yeh, just as things were getting spicy. Ah well, I'm sure there will be another argument about barrel length and accuracy at some point soon on here...? -

Yeh - I know right? Whilst I'm pleased with this little project from a technical and learning perspective, I've realised pretty quickly that just because you can do something, it doesn't mean you should... ? Rest assured all stock parts have now been re-fitted. That really does look like a very cool project - how did you go about printing the shell? It looks almost like SLS?

-

Ok, last of the Speedsoft content - moving on to other projects now. Made a hand guard using 40mm PVC pipe that acts as a sleeve over the stock outer barrel. Barrel nut epoxied to one end, and a cap that is a tight interference fit on the outer barrel epoxied to the other. Very solid given the soft plastic of the pipe, no flex or wobble. Perfectly usable I reckon, assuming you don't plan to use it as a club and wrap it around a tree. I call it - the fleshlight....? (Note - no guns were harmed in the making of this project, all bits will be reverted back to stock shortly.)

-

Taiwangun Shipping Disruption (Brexit Related Content)

Speedbird_666 replied to Speedbird_666's topic in General Discussion

-

Indeed Herr Hamster. My overall (long term) aim is to produce the most minimal viable gun that will work around a V2 gearbox. That will mean a receiver of my own design, but I'm not skilled enough to model such a thing yet...however these smaller projects have helped immeasurably. It's unlikely that I would ever rock up at a field with such a setup myself though, because that would just look stupid - fat middle aged guy thinking he's a speedsofter? Nah. However my middle son (13) loves playing airsoft, but has no real interest in realistic guns/RIFs (he sees the hobby almost as big-kids extension of Nerf), so he has no problems with rolling with such a gun if it's light and easy to shoot.

-

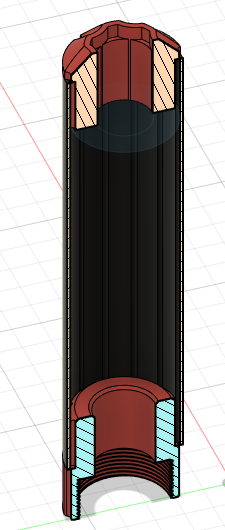

Yep, Fusion 360 models the threads. I send to model to Cura, which in turn slices it and creates the GCode for the printer.

-

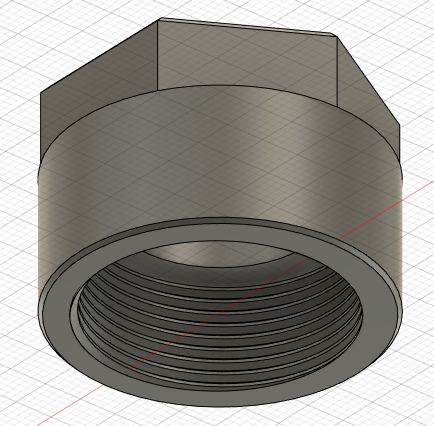

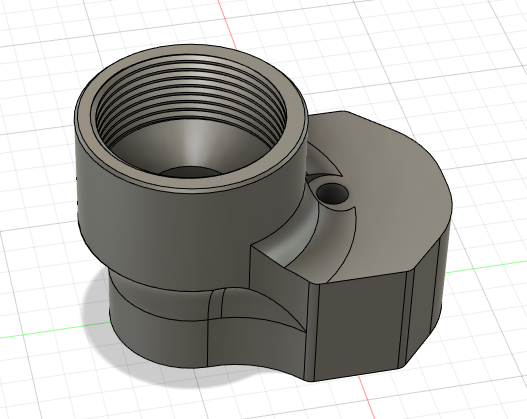

Modeled in Fusion 360 (M32x1.5) and printed them - they needed to be scaled up by 2.5% to account for slight inaccuracies in the 3d Printing process. So I needed to remove the proprietary barrel nut for the stock G&G front end - so had to design/print a tool to do it: I knocked up a 'proper' barrel nut to check barrel fitting - y'know I think speedsofters have got the right idea when it comes to ergonomics, this thing feels super light, balanced and point-able: (I know, I know, haters gonna hate - this is an exercise in curiosity more than anything else) I intend to make a whole front-end using a ~40mm Carbon tube epoxied onto a 3D printed barrel nut, a printed outer barrel stub at the receiver end, a printed barrel stabiliser cap at the front, with the inner barrel free-floating in between.

-

15deg stock adapter (apologies for those easily triggered by Speedsoft-type stuff ?? Took a few attempts to get the scaling right, but I got AEG barrel nut threads nailed:

-

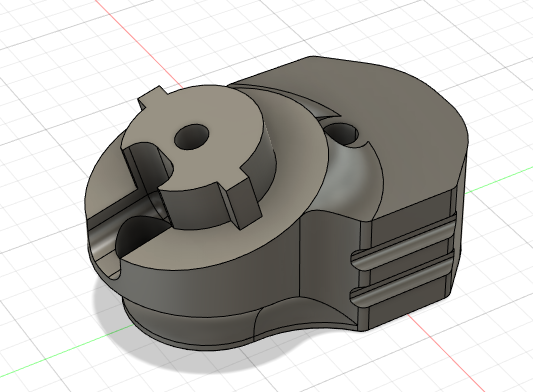

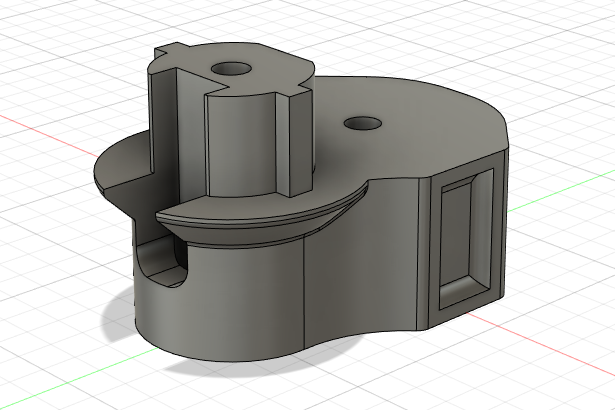

I'm modelling a reasonably accurate V2 GB (+/- 0.1mm) in F360 to use for an own-design receiver project. Took a few 1mm test prints to get the footprint measurements dialed-in Progress so far - I won't need all the details (not bothering with bushings and screw holes etc.) but I will model the trigger hole, rear pin hole, grip frame slot/holes, and the selector area on the other side.

-

Result. I would be inclined to reduce the size of your powerbank to drop some weight - it's a bit overkill for two tiny fans pulling ~0.06A each. You would be looking at ~120mAh, which would take even a cheap £2 Poundland 2200mAh Powerbank 16 or so hours to discharge.

-

-

Macks airsoft dreamers of the week thread

Speedbird_666 replied to Mack's topic in General Discussion

When you try too hard to get the 'battleworn' look -

The 'What have you just bought' Thread

Speedbird_666 replied to Cameron364's topic in Guns, Gear & Loadouts

This. I have several BCM style grips - I run them all angled-forward. -

That's a really good idea! Do you print the threading or tap it after printing? What thread is the buffer tube?

-

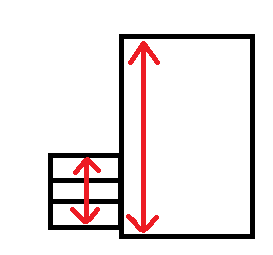

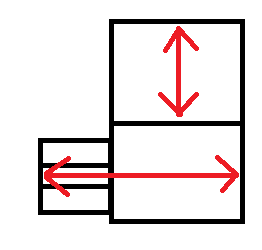

To answer your questions: - Yes, I like to model the parts myself wherever possible, although you can find a fair bit of stuff on Thingiverse. I use Fusion 360 as my modelling software and Cura for slicing the model for print. If you want to design more 'organic' (such as your skull masks) I know people use software such as Z-brush and blender to produce the models, but I have no experience with these. - That's a difficult question to answer, as there are several main types of printable plastic (PLA, PETG and ABS), and numerous sub-variations with additives and special properties. I'm using PLA+, which is less brittle than normal PLA, but at the cost of some mechanical strength. Normal PLA will catastrophically fail (i.e. snap or shear) , PLA+ is more likely to bend and stretch. In the example of my drop-stock adapter, it's been printed in the least-optimal way for strength (the receiver extension for the buffer tube could potentially fail under enough force) due to the way that a printer lays down plastic layers on top of each other, but it was easiest to print it that way. In reality, the adapter feels more solid that the plastic G&G receiver it's attached to and there is zero flex, but time will tell. I have an idea for the next version to make it a 2-piece design that means that the receiver stub will be printed in a different orientation to the rest of the adapter. Current design print layer direction vs 2-piece design: - I'm using a Creality Ender 3 V2 bought directly from the Creality UK warehouse. It was on sale for £168 with free postage, but I think the price is back up to around £200 now. I'm running it pretty much stock with no upgrades other than a quieter fan for the PSU and yellow bed springs. I plan to add BLtouch (self leveling sensor) and some new bowden tubing at some point soon though.

-

Now that is a cool (no pun) idea. I didn't realise you could get blowers that small. I could potentially integrate those into the sides of my paintball goggles. My only concern would be fan noise?

-

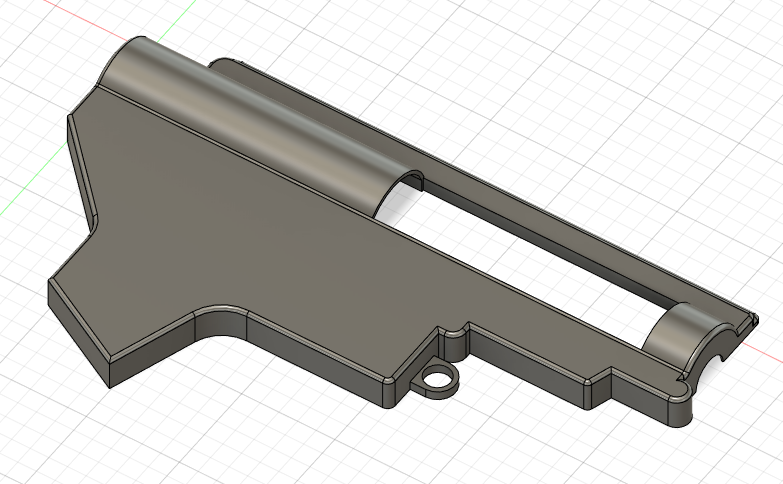

Job done. Perfect, tight fit first time (wasn't expecting that, hence the Red filament as I'm running low on black). Will print a black one shortly now I know the tolerances and fitment work.

-

I see someone is flogging G&G Drop stock adapters for £25 a pop. Decided to design my own for my son's gun (he wears a paintball mask). Not quite as slick as their design, but an hour or so of CAD work gives me this. Prototype is on the printer now.