Pseudotectonic

Members-

Posts

471 -

Joined

-

Days Won

2 -

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Pseudotectonic

-

Recommend me a speed loader

Pseudotectonic replied to Enid_Puceflange's topic in Guns, Gear & Loadouts

Odin clones -

@EDcase just an observation, that solder joint in the picture is a cold joint and might break or overheat (due to poor conductivity) And yes you can charge an AEP 7.2 V battery, just charge it with NiMH settings (or whatever chemistry it is)

-

I built an XL4015 for breaking in a new motor, cost me £4.60 (plus wiring etc) and you can change the voltage to whatever you want with the display, plug a battery in and it will run a good while at 1.5 V, above this voltage the motor gets too warm and warm is no good for the magnets Good for seating new carbon brushes and cleaning the commutator with a qtip and a drop of brake cleaner The carbon brushes are more durable than I thought tho, you can spend days running without fully seated the new brushes

-

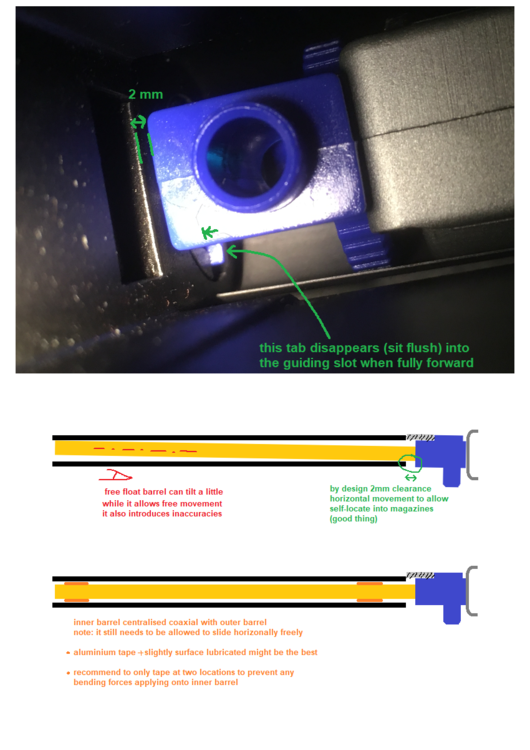

PS I think the air seal issues you are talking about are mainly coming from the misalignments of the axis and all the wobbles and misalignments axially between inner barrel vs outer barrel vs upper receiver vs gearbox nozzle. I think the horizontal movement is by design and not a major cause of air seal issues. I don't know exactly how much extra mm the nozzle goes beyond the hop rubber sealing lip, but I suspect it should have enough mm to cater for this 2 mm movement by design. It would be all the tilting that makes the nozzle not coaxial and perpendicular with the hop rubber lip causing air seal issues. If it is aligned and coaxial, it shouldn't matter whether the nozzle is inserted by 3 mm or 1 mm, but I am just theorising here.

-

@Rogerborg I got a Specna Edge as well and after tinkering a bit I discovered a few things: The inner barrel assembly is free floating inside the outer barrel and can move freely horizontally in the axial direction. The hop unit is spring loaded on the outer barrel, which pushes it against the gearbox. But when everything is assembled, there is a whole 2 mm of clearance for forward movement, obviously by design for self-locating into magazines. The hop unit feeding tube is chamfered for this purpose (or made more chamfered to improve magazine locating, as you have done). The inner barrel has surprising amount of wobble inside the outer barrel because it is just free floating inside. All these wobble up and down and side to side, and tilting in any direction, is detrimental for self-location into magazines because when the magazine comes in, there is too much room for error and the hop unit can be outside the correct zone for self-location. The inner barrel can be shimmed or "stablised" for better accuracy, but this needs to be allowed to move horizontally without friction for the self-location to work. Similarly the outer barrel can be shimmed on the inside diameter of the upper receiver hole (as opposed to using barrel nut shims to try to hold the barrel in place by sheer friction), to centralise the axis. Besides accuracy, this has added benefit to tightening the guiding slots for the hop unit so there is less chance for the hop unit to rotate axially which again throws off the location of the feeding tube into the magazine. You can test the forward movement of the hop unit by pushing it forward with fingers through the magwell.

-

The hop unit should actually be moving forward or backward slightly to locate itself to insert into the feeding port of the mag Maybe your hop unit is slightly deformed so it is not sliding smoothly, or not inserting itself smoothly into the mag Can you turn the gun upside down and take a picture of the mag well with strong lighting?

-

They all seem to made of steel wires body Are there any that is completely plastic?

-

I'm surprised m120 can do the Orion in, could the new cylinder is a bit bigger than original and it is tight on the shell? Or the cylinder head? Or combination of both?

-

below .35 ---> maple leaf macaron (or super macaron) + omega nub or similar above .35 ---> maple leaf MR hop + omega nub or similar

-

For brass instruments like trumpet or trombone they have these "snake brush" which is some nylon brush at the end of a flexible spring (plastic coated to prevent scratching) If we make something similar for airsoft with a small brush (wholly plastic like a toothbrush) tied to a paracord or something non-metal, it will work similarly or like a real steel bore snake Key thing is everything has to be plastic because it has to be softer than aluminium and brass to prevent scratching Toothbrush exists so the technology is there, just a matter of making it sized correctly to go through 6 mm tubes Bonus feature: make it clip onto its own tail and make a loop, and then it can be powered by you full autoing the gun for automatic cleaning

-

Can you upload the form?

-

oh it could be the hop, if you increased the hop, the FPS will drop, because more force is being applied to spinning the BB if you touched the hop any amount at all, it can affect the FPS a little bit it cannot be battery, battery does not really affect FPS

-

maybe fire a few more shots to clean out the lint/dirt that got pushed

-

Btw the inner barrel can be stabilised (centered) to the outer barrel if you wrap some tape around it which helps to reduce the barrel rattling and reduce any vibration from travelling along the brass I do it at two points, one towards the front tip and one towards the back near the hop unit, with only two points you won't be applying bending force to the inner barrel if there is any knocks or bending of the outer barrel, because you need a third point to bend a straight object

-

Take this as example, from this view (and the receiver opening) if you turn the dial down, it means up, the hop rubber will come down, and the BB will go up (seriously just turn counter-clockwise to reduce hop, which is what you are trying to do in your situation)

-

AEG has several sources of sound: motor and gearbox sounds, piston sound, and muzzle pops Motor and gearbox sound is mostly generated by meshing of gears and all the little mechanisms rattling, which can be minimised from source with shimming and tuning the overall rigidity of the system. Normally this is transmitted via resonance or reverberations through the gearbox and AEG body itself, so if you can dampen this vibration around the receiver area this can be reduced. Piston sound is a loud pop from the piston hitting the cylinder head. Similarly this can be dampened however you want with piston head + piston head combos/trickery, or something done to the cylinder or gearbox or receiver to dampen the vibration and transmission. Muzzle pop is probably not as loud as the above, but first you want to contain the expanding volume of air, and secondly dampen the vibration from being transmitted via the smooth cylinder shape of the suppressor. These are all essentially sound insulation problem and there are several principles for dealing with this. Sound travels through air so any unnecessary air gap can be sealed to contain sound, but this is perhaps not practical for an AEG. Mass absorbs sound, so in theory filling your receiver and suppressor with concrete would be best but obviously this is not practical. Another way is material science, make it less resonant so it absorbs the vibration (i.e. sound) instead of transmitting it into the air, usually this means a suitably soft material, or even better, a composite material like applying 3M 2552 Damping Foil Tape so the vibration is turned into heat rather than being allowed to vibrate freely thus transmitting into the air. Foam does not do much because while it slows the expanding air, it does not really dampen much vibration of the aluminium can that is holding it. So in theory perhaps the best airsoft suppressor will firstly have damping foil applied to interior (to deaden the can body), and then layers of heavy weight acoustic rubber floor matting (the type used for soundproofing floors, use heaviest grade you can find), then the inner most post leave just enough diameter for some baffles (material doesn't matter) to allow the air to expand and be slowed before it travels towards the end of the can, you only need maybe about the same volume of the gearbox cylinder or even less. Then if you put some damping foil on (inside) the receiver and gearbox and cylinder(I have some on my motor) then it will be even quieter, if you are going for ultimate stealth SD6 build. Somewhat relevant video https://www.youtube.com/watch?v=SK9qpGqBBmg you don't need a whole lot to be effective. Only downside is the 3M stuff is expensive and I am still looking for alternatives. This is not normal aluminium foil tape because this stuff has 0.254 mm thick aluminium (~250 micron) as opposed to the 30 to 50 micron thick common stuff, and you can't just double up the normal stuff because it doesn't work that way.

-

I agree, the wording is vague, "completed" could mean many things, e.g. if all the product information is uploaded, so the advert is "completed" and no further editing is expected if the duration of the listing has expired, therefore the listing duration is "completed", but the item may be unsold and there could be a new listing with the same item if the product is unsold, but the seller withdraw the advert, marking the listing as "completed" While "sold" cannot be interpreted any other way therefore a better alternative

-

Competitive Tournament in London

Pseudotectonic replied to Toxic Raider 2-1's topic in Other Events and Meets

Hit calling will be shit due to low light -

Pretty sure you can just replace with the white one https://www.ikea.com/gb/en/p/skadis-pegboard-white-10321618/

-

Competitive Tournament in London

Pseudotectonic replied to Toxic Raider 2-1's topic in Other Events and Meets

what reward? -

Wow that is labour and skill intensive but certainly a much nicer result than tape

-

I doubt very much the 5 mm layer of air is going to dampen much energy from an incoming piston at 300 mph unless there are videos proving otherwise Seems to me it is more for AOE correction

-

Nice, you cut it yourself? Does it free float or glued down? Yes it should have a little play for free movement, a bit like shimming other gears

-

How to stop the bolt catch from rattling?

Pseudotectonic replied to Pseudotectonic's topic in Electric Guns

I ended up using some 3M VHB tape, seems to stick quite well, time will tell if it holds up