Pseudotectonic

Members-

Posts

476 -

Joined

-

Days Won

2 -

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Pseudotectonic

-

Did they force you to pay for the repairs? Or did they just try to sell you things you don't need

-

Need a spade connector.... what size, and where from?

Pseudotectonic replied to RostokMcSpoons's topic in Electric Guns

I actually have that same style of crimping tool but it doesn't have an exact crimp for 2.8 mm for some reason and I ended up having to use needle nose pliers to do a better job, in principle you just need to make sure you apply enough crimping force to make it secure but not a deadly amount of crimping because you need to retain the diameter for conductivity -

Yes exactly, radial and axial forces please (some vector arrows will do) Although I imagine in reality it is in all directions because of vibrations and airsoft physics and whatnot

-

It's a cosmetic part I know but it is just rattling around literally held in place by the upper and lower receiver What is the most solid way of fixing it in place so it doesn't rattle around?

-

Need a spade connector.... what size, and where from?

Pseudotectonic replied to RostokMcSpoons's topic in Electric Guns

2.8 mm -

It seems your forces are going "one way" from the motor, what about the spring load coming back, does it apply any load on the bevel gear and does it modify the radial load directions? For sake of my understanding do you mind drawing some arrows on this diagram?

-

How did you calculate the 3N on the other side? And the 2N axial force?

-

For UK sites you can generally go just under 350 fps with 0.2s (1.14 joules), so if you try to reach 330 fps (1 joule) it should be good with some safe margin for variance, so the m100 spring should normally be ok For .25 to up to .35s I would suggest the maple leaf super macaron hop, since you are using 0.25 which is on the lighter end of the spectrum a 50 or 60 degree rubber would be good, and also get the maple leaf omega nub so the hop is applied correctly And see if you are happy with the results, if not you can think about the barrel but I don't think it is as critical as the hob

-

For gun room/armory interior design, it seems there are generally two common styles, either you go 1. grid mesh/pegboard/slat wall for a utilitarian look, or 2. fancy cabinets https://www.thefirearmblog.com/blog/2016/03/25/top-100-best-gun-rooms/ You might want to think about coordinating a colour theme for the room (e.g. grey pegboard with grey wall and not just random colours) and designing your lighting for wall displays, i.e. spot light bars on the ceiling (Best lighting are found in museums so you can get some ideas from museum lighting design)

-

In terms of mixing, it appears that ALL the manufactures (at least on Evike) would agree on bearings on bevel and bushing on spur and sector Not sure if this means anything https://www.evike.com/index.php?cPath=28_24_68_518

-

Anyone know the model of this glove?

Pseudotectonic replied to hsin1970's topic in General Discussion

What rifle is that? That quad rail looks very short -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

The ones I'm using are PTV-6R0V305-R https://www.digikey.co.uk/en/products/detail/eaton-electronics-division/PTV-6R0V305-R/13404670 (They are 3Fs) Resistor is https://www.digikey.co.uk/en/products/detail/yageo/FMP100JT-52-2K2/9107445 LED is https://www.digikey.co.uk/en/products/detail/broadcom-limited/HLMP-1601/637567 Wire is 16 awg Deans is deans Btw I'm studying the pros/cons of omitting the resistor because the LED alone draw more than enough milliamps to function as draining resistor (with its built-in resistor), perhaps this is something you can try -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

@kadamski I agree with more testing with LiPo. In actual fact, rather than me buying a bunch of LiPo and just simply measuring the trigger response in milliseconds, it would be more economical and informative for me to make another unit and simply send it to you to be tested with your LiPo and looking at the currents and voltages with the scope, if you don't mind the work and sharing the results of course. That will be more insightful than me measuring with Audacity. In fact the offer is up for anyone happy to test it, the condition is you need to have a scope to look at the currents and voltages (with LiPo) and share the results. (I will pay for postage and everything) -- And btw, I have uncovered the ancient texts from the "Airsoft Mechanics" website (2005) somehow stored on the Internet Archive. There is an article and some forum posts which some interesting discussions that somewhat mirror the discussions here... https://web.archive.org/web/20110511090621/http://www.airsoftmechanics.com:80/home/content/view/16/30/1/0/ https://web.archive.org/web/20090726234228/http://forums.airsoftmechanics.com/index.php?topic=78. (sadly only the first page was saved) In the article they say they tested with some salvaged PC motherboard "2200mFD 10V" capacitors which I think is a mislabelling on their part. Because a 2200 mF or 2.2 F 10 V capacitor would be firmly in the realm of a supercapacitor (rather than a normal capacitor) but I don't think you can find these on PC motherboards. Also looking at their small picture it seems to be rather a 2200 uF (which is 0.0022 F) capacitor which is more plausible coming from a PC motherboard. In their text they refer to "microfarads" instead of "millifarads". Although their caps were in the millifarad territory, which I don't think would work, somehow they say they have improved ROF by around 3% and an unknown amount of reduced voltage drop (I think their image is missing). I don't know what to make of this. Maybe it is down to the fact they were using some 8.4 NiCd on some TM motor. The forum did confirm the OP didn't improve trigger response, although another person say it did but with unknown capacitors. All without any actual numbers so I don't think it means anything other than confirming my maths about they need more farad than a few millifarads to actually improve trigger response. -- And for the sake of continuity here is the Reddit post for future reference: https://redd.it/18k2324 -- Also semi-relevant: https://www.youtube.com/watch?v=tKki89sq0XY -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

I thought it is common knowledge that higher load means higher current, and that of course includes the initial spike, and the measurements confirm that. I am not sure what you are trying to get at, but I think if you are trying to theorise higher load will not induce higher current, not sure if that is a feasible exercise because I think it goes against conventional wisdom and also empirical data. If you are talking about the micro events at speeds of electromagnetic waves (which approaches speed of light) maybe you are onto something but I don't think this affects the "macro" effects of higher load inducing a higher inrush current. https://youtu.be/O-WCZ8PkrK0?feature=shared&t=666 -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

I think the rabbit hole of brushed DC motors and inrush currents goes deep and I'm not ready to jump into it, sometime to do with back EMF or something -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

That thing looks incredibly fun to drive so I take that as compliment -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

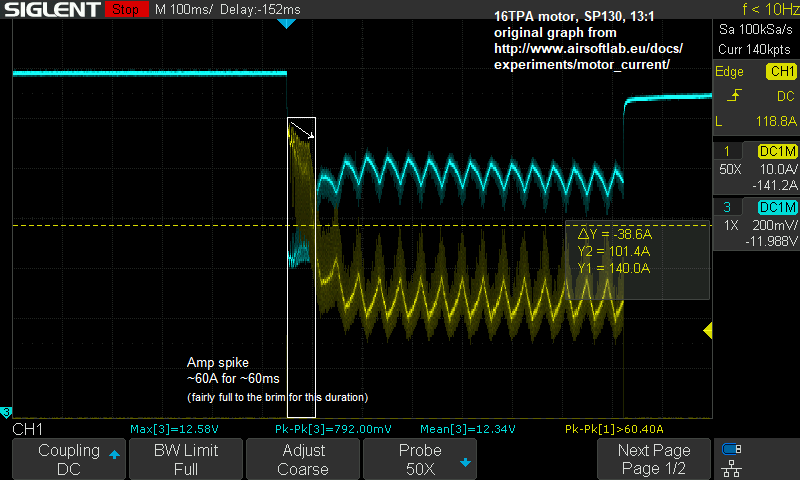

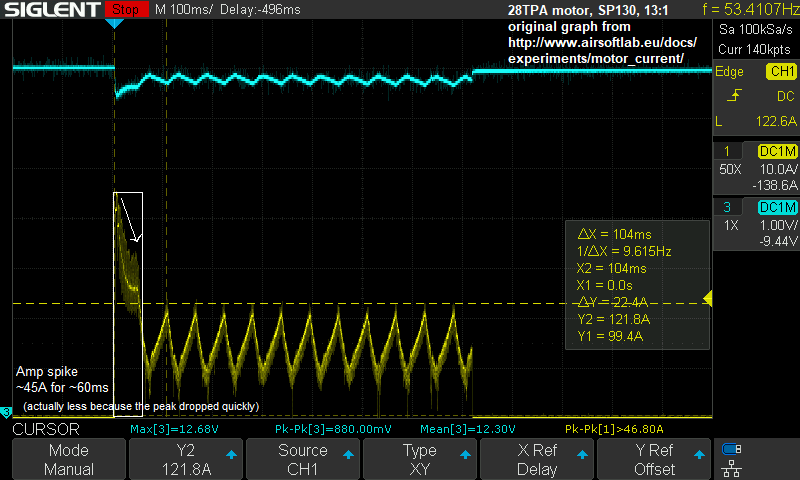

I can perhaps chip in about the motor question, if we go by this graph (another semi-educated guesstimation of mine) 16 TPA is on the high speed side, and 28 TPA would be in the high torque camp. And about spring vs current, the higher the load, the higher the current draw from any motor, that is completely normal and not anomalous at all -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

@Sewdhull Yeah definitely a lot more testing and more data is going to give more insights, but again I don't have the equipments for this, but I am hoping anyone can just make their own units and test the working principles which should be the same even if the components are similar I think I have dropped enough hints as to what supercaps I am using and how to actually wire them, but the working bits are really not complicated, the one I built is using some 3F supercaps, they are just wired in series to make total 1F with 18V headroom, and then parallel with the batteries, I mean I think the photo alone should have enough information, but for avoidance of doubt the drain resistor is a 2.2k ohm 1W, and the LED has a built-in resistor so I don't need another one for current limiting, plus the wires, plus the heatshrinks, plus the deans, that is literally all the parts @Adolf Hamster Is it the Lonex BAW system? Never seen this before, very interesting, it seems they are using the buffer tube as some sort of recoil system but the gearbox seems to be a traditional v2 gearbox I guess if there is ever a linear solenoid system, probably the best way is use some off the shelf units if there is one that fits (I have no idea), for cost and repairability reasons -

A Call for Revolution: Supercapacitors in Airsoft

Pseudotectonic replied to Pseudotectonic's topic in General Discussion

@Adolf Hamster Precocking: should benefit even more, yes. More space efficient than simply another battery for surge power: yes. Brushless motors: possibly can still benefit from the more stable system voltage, but someone needs to test this. Linear solenoid: very interesting idea, but I think it also has to do with the architecture of an M4 (or any rifle shaped object) and how to make use of the space, and I suspect using solenoids may not be the most effective strategy in terms of making use of the space available to translate electricity into moving a piston of a particular shape, I don't know. Btw, the Systema PTW Infinity gearbox is somewhat innovative in this regard and I suspect their design may be a step in the right direction. Although I'm not entirely sure considering complexity and cost etc. @Sewdhull Many thanks, for LiPo, yes it should still benefit from it (but not as much as NiMH I would imagine), the graphs were measured with an 11.1 LiPo so certainly the theory would still apply. Not sure about LiFe batteries but I would think the premise still stands, my understanding is LiFe does not have dramatically improved peak current over LiPo, the only advantage seems to be in safety if I'm not mistaken. Good point about ESR. The guy at Airsoft Lab actually says something similar about ESR being more informative than the C rating. (see below) And by the way, someone from Reddit questioned the voltage sag which prompted my to re-examine the whole voltage sag issue. I have noticed I have actually read the graph wrong and in those examples the voltage is not sagging as much as I thought (the vertical scale is off for the blue voltage curves), however, upon investigating this subject the same website is proven useful again with http://airsoftlab.eu/docs/opinions/c_rating/ which actually shows the Vdrop of several LiPo batteries at different current amps. And I think the data is potentially very interesting (I will just repeat what I typed in Reddit below) and potentially making supercaps even more useful: The Vdrop at nominal currents are wildly different from one LiPo to another Their top of the line LiPo of 2.2 Ah (which is too big for an M4 stock anyway) can do 110A with just 5.5% Vdrop However the other brands which are probably more representative of your average LiPo (used by "teenagers") goes from doing ~30A with 15% to 25% Vdrop, to 72A with 50% Vdrop (!) If we extrapolate the data we can assume the average LiPo inside an M4 at 60A is going to Vdrop in the region of 40+% albeit ± a big margin with different brands So the assumptions are really not too far off at all, and depending on your LiPo brand (which is really a mystery because no one has tested all of them) the benefits can skyrocket if you happen to have a below average LiPo unknowingly, which is 50% of the chance!!! 40% voltage sag is a big assumption, I know, but the key take away is LiPo quality vary so much that I think 40-50% voltage sag at 60A (as I understood originally) is still entirely within the realm of possibility, even with very good probability, so much so it only reinforces the whole premise of using supercaps to plug the gap in surge power performance, in my opinion. -

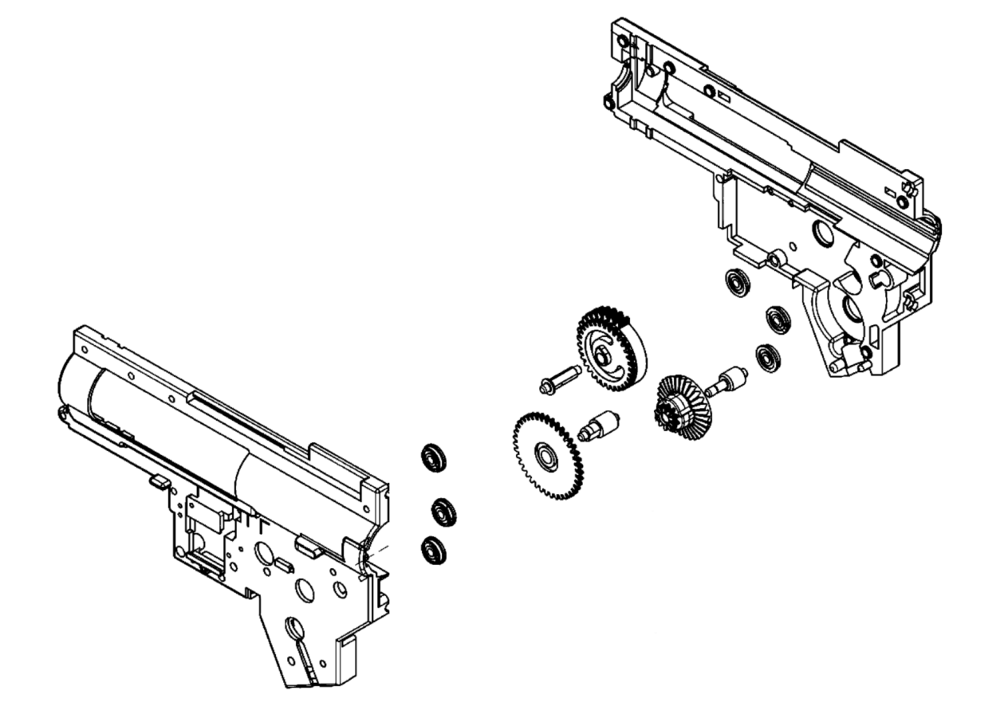

Introduction: The lost art of capacitors in airsoft The mythical powers of "capacitor banks" is not a new idea in airsoft, but the original sources and theories are lost in time, with only faint forum posts remain (all the links are dead in https://www.airsoftsniperforum.com/threads/capacitor-banks-revisited.8688/). In my pursuit of the ultimate trigger response in AEG, power supply remains a big unresolved issue because batteries (LiPo or NiMH) do not really give enough oomph for lack of a better word. We need something better, I thought, we need supercapacitors. And so I set out to rediscover the elementals of such dark magic from scratch (but based on the same principles). And I believe I have revived this magic which I will share my formula below. And dare I say, the surface of this dark art has not really been scratched, because the predecessors either did not use enough capacity (some examples were in the order of millifarads which is not nearly enough), and did not really use the correct type of supercaps (stacked coin cells hybrid types are not capable of high amps). And perhaps the right modules were not available until very recently, so this study will also represent a fresh look into this subject. If you want the bottom line: Why supercaps at all, isn't LiPo good enough? In short (excuse the pun), LiPo cannot provide sufficient peak current for the amp spikes during start of motor which is often in the region of 45-60 A. These micro-events of shorts (from the perspective of the battery) is also a main pathology of LiPo degrading and swelling over time. These spikes happen every shot in semi, and in the first shots in full-auto. This status quo practice of relying on abusing LiPo as sacrifice for performance does not sit well with me, because firstly it is electrically primitive, and secondly it is a safety risk in this toy gun industry that I think is unnecessary and should be done away with, at least as much as possible. The whole premise of using supercaps is to provide a voltage reservoir for surge power during these initial amp spikes. This is needed because these amp spike often exceed the capabilities of the battery (even LiPo) and the batteries drops voltage in response (for milliseconds) and unable to feed all the current needed for this initial spin-up of the motor. In theory, it can achieve the following: Surge power for much more responsive motor, resulting in snappier trigger response. Stabilised voltage supply for full-auto, resulting in better ROF. Protecting batteries from surge currents, prolonging their lifespan and minimise risks of LiPo fire. My evidence and theorisations are as follows. What is the actual energy requirement? To begin to figure out the solution, we need to ask, what is the minimum capacity to be effective? We can analyse these two graphs from airsoftlab.eu for theorycrafting. http://www.airsoftlab.eu/docs/experiments/motor_current/ To figure out the ballpark of energy levels we are talking about, I have picked two cases representative of a high stress build (with a 16 TPA motor) and a more optimal build (with a 28 TPA). The first graph is with 16 TPA motor, SP130, 13:1, to illustrate a typical suboptimal setup with a low torque motor paired with a high stress spring and gear ratio. The second graph is with a more comfortable 28 TPA motor with SP130 and 13:1 to show a more efficient setup. Just by eyeballing the graphs (and the blog), we can character these spikes (and the energy required to tame them) to be about 45A to 60A, for a duration of about 60ms. 16 TPA: 28 TPA: What do the numbers mean? There is a simple answer, and a more complex one. A simplistic way to translate this to farad (the capacity we need), using the 16 TPA setup as example, 60A for 60ms is 3.6 coulomb, which at 11.1V is about 0.324 F. For the 28 TPA example, this would be 2.7 coulomb, at 11.1 V this is 0.243 F. Therefore we can say our ballpark figure is about 0.25 F to 0.33 F as a minimum target. If we are aiming to create a unit that can work with worst case scenario, let's go with 0.33 F. However because supercaps discharge their voltage linearly (meaning their 11.1 V drops down to zero as it discharges over the 60 ms), we can think of it as sharing the workload with the battery in a 1:1 ratio (this is very simplified), meaning it is only doing half of the work while the batteries still need to supply the other half of the current (which is a big improvement already). Here is a prediction: In this predicted scenario, the amp spike seen by the battery should be reduced to less than half, because the supercaps will react faster to supply the spike, but as the supercap runs out of voltage, the battery will notice the difference in voltage and catch up, eventually supplying the full load in full-auto, but at a much improved stability. And as the trigger is released, the current stops, the supercaps are charged up again to battery voltage as the battery recovers from voltage sag. We can offload even more work from the batteries if we multiply the supercap capacity (say 3 times, to 1 F) so the they will perform in a 3:1 relationship i.e. 75% of the work are done by supercaps, which will stabilise the current even more. If we go bigger, say 1.66 F, the ratio will be 5:1, or 83% of work being done by supercaps. (The actual result will probably be better, the ratios e.g. 1:1 at 0.33 F are just conservative notional numbers I made up for ease of explanation. Supercaps are more responsive than batteries, and the overall lowered battery stress should further reduce overall voltage sag, so the battery should see less than 50% of the peak current, but I don't have the equipments to proof this hypothesis.) So let's say our notional baseline is 0.33 F, now we just need to implement this theory. Designing a supercaps unit Here is our goal: 1. Supercaps with total capacity of 0.33 F or more, bigger the better. 2. Voltage should be ok for airsoft usage. (Say a fully charged 11.1 V LiPo is around 12.6 V) 3. Overall size to be small enough to fit in a typical buffer tube, with room for cable management for most cases. Smaller the better. 4. (Bonus feature) built-in safety to drain residue voltage when unplugged. 5. (Bonus feature) LED to indicate presence of voltage. The obvious (and probably the only viable) strategy is to use 3 no. of 5-6 V supercaps in series to give us a 15-18 V headroom for the maximum 12.6 V we are expecting from a fully charged 11.1. The first problem is selection of supercaps. The second problem is designing the whole package that can physically fit inside the buffer tube. Long story short, here is my blueprint: (Just connect the supercaps in series, and then parallel with the batteries, I don't have a drawing) The Eaton supercaps I am using are the highest capacity that can still fit inside a typical buffer tube and wiring, and with one of the better ESR in its class, and can theoretically suffer 115 A of thermals over 60 ms, and tested to MIL-STD 202G for shock and vibration. They are wired (I'm using some fancy SPEC 44 16 awg wires) to a connector that goes between the AEG wire and battery wire, so it is completely plug and play, and removable for safety and for storage. It can in fact be stacked up (if you have multiple units) to give extra performance. For extra safety I have included a bleeder resistor to discharge the residue voltage in maximum 3 hours after it is unplugged. Also for safety (and aesthetics) I added an LED for visual indication of voltage presence. I am tempted to call it the PASTA 1000 (Pseudotectonic Advanced SupercapaciTor Array 1000 mF) but any suggestions welcome. Here is what it looks like in real life: Testing AEG: Specna E-19, completely stock (which has an X-ASR mosfet preinstalled.) Battery: 9.6 V NiMH, fully charged, measuring about 11.32 V when testing. This is just a simple A/B test to see if the supercaps work at all. I will simply alternate between plugging and unplugging the supercaps several times, then take measurements with groups of 6 to 7 shots, until the data are fairly consistent and/or a pattern can be identified. The groups are measured in Audacity and averaged and rounded to nearest millisecond. Also note I am not testing with any magazine inserted because A. that is not going to make massive difference either way and B. it is one less variable to worry about and C. if a BB goes off it is going to affect my measurements with sound. The results: Stock setup (without supercaps), group #1: Trigger response: from trigger action = 83 ms, from motor spin-up = [data missing] ROF: ~17.17 RPS With supercaps, group #1: Trigger response: from trigger action = 81 ms, from motor spin-up = 57 ms ROF: ~17.48 RPS (+1.8%) Stock #2: (I stopped measuring full-auto because it is getting too loud for the neighbours) Trigger response: from trigger action = 96 ms, from motor spin-up = 64 ms With supercaps #2: Trigger response: from trigger action = 74 ms (-23%), from motor spin-up = 62 ms (-3%) Stock #3: Trigger response: from trigger action = 90 ms (+22%), from motor spin-up = 69 ms (+11%) With supercaps #3: Trigger reponse from trigger action = 71 ms (-21%), from motor spin-up = 62 ms (-10%) Stock #4: Trigger response: from trigger action = 84 ms (+18%), from motor spin-up = 68 ms (+10%) With supercaps #4: Trigger response: from trigger action = 76 ms (-10%), from motor spin-up = 62 ms (-9%) Stock #5: Trigger response: from trigger action = 80 ms (+5%), from motor spin-up = 69 ms (+11%) With supercaps #5: Trigger response: from trigger action = 75 ms (-6%), from motor spin-up = 61 ms (-12%) Analysis of results: Definitely a noticeable audio difference in trigger response. The only way to describe it is it sounds more "instant" and there is less of the spin-up whine. I am not sure why the groups vary quite a bit (maybe battery and/or gearbox settling) but I think it is fair to say the supercaps are making a difference. If we average the data after group #3, with supercaps, the overall trigger response is about 14% improved, with the cycling time from motor spin-up is remarkably consistent at about 11% improved. The shorter lag time from trigger action to motor spin-up can be explained by the voltage stability provided by the supercaps. Overall I didn't know what to expect but I would say 14% improved trigger response is pretty good. It is definitely not a negligible difference, and definitely noticeable when compared side by side. But going by feel alone, it definitely feels a bit more snappy. ROF is probably improved a little bit, but more testing needed. The installation: This may be the only draw back. To actually fit the unit inside the buffer tube along with the X-ASR is a massive hassle, which I have to actually remove the original long heat shrink around the three wires to get them to flex, and re-crimp two out of three of the spade connectors to the X-ASR because they were damaged by too much bending. And even when the supercaps are in, it is still very stuck and you need to wrestle the wires to get the battery on and close the butt plate. Although I have done it with the stock fully collapsed and if I install it with the stock a few positions out, it will be easy. Once it's on, it works. But it is definitely not ideal if you have any in-line mosfet like mine. However if you use a proper mosfet inside the gearbox and just have wires in the buffer tube, it should fit very easily, potentially upping the supercaps to 5 F ones for even better trigger response. There is no noticeable sparks or heat or anything when install and in use. It simply lights up when you plug it in and it just works with zero drama. Here is how it looks like installed, with a fully collapsed stock, and without the stock: (it barely fits) To uninstall: If the battery is disconnected with just the supercaps plugged into the gun, the gun will barely able to do one shot and the second shot will be stopped by the mosfet because the voltage will have dropped too low. This is just as expected and fairly consistent with the maths. The LED: When you unplug everything, the LED stays on but slowly dims down over the course of about an hour (just as designed). This shows the draining resistor and the LED are all working as intended. I could also feel zero heat from the resistor, which is great and again matching expectation. The LED still visibly faintly glows even at as low as 2 V so it works perfectly for its purpose as a voltage indicator. The red LED is pretty to look at, although I might change the colour to something like blue or green, because the red can be mistaken as error from the mosfet. I might also move it to the "top" side of the "plug". Conclusion of experiment: The prove of concept is a success. Most importantly there is certainly a performance benefit (14% in my test). All the maths check out. The unit is fully functional and fully match the expectations. It literally is plug-and-play. The installation can be a hassle for wire management but that is purely down to physical space and should not be a problem if you are not using in-line mosfet. Conclusions and speculations More testing is needed with other setups, if you would like one for testing I can make you a copy for a fee. The tech tree can potentially branch into AKs or other platforms or even external compartments, but I don't have any of these for development. Here is a summary of what this device can do. The biggest feature for me is safety, because when the LiPo (or any battery) is shielded from stress they are much less likely to puff up over time and starting a fire. Another key thing is of course the performance. It works very well in my very first little experiment. Electrically the overall voltage floor and current ceiling is improved. Adding supercaps is a bit like transitioning from NiMH to LiPo, but on steroids. There is also where the drawbacks are, because a mosfet is probably a good idea for such power, and if you want to collapse the butt stock you will need a more advanced mosfet that sits inside the gearbox rather than the buffer tube, for cable management reasons. (If you copy what I did you will risk breaking some wires) In terms of use cases, it will benefit NiMH the most because the performance is suddenly brought closer to that of LiPo because the performance gap is effectively closed, making NiMH a viable option again. In fact it makes NiMH better than LiPo because NiMH is much safer. This is also a must if you are chasing the state-of-the-art trigger response or battery efficiency in any build. It will also help with cold weather performance. And the best thing is, this is essentially a "free upgrade" because it is an entirely new component added to the system, it does not replace or compete with any existing parts, and it doesn't need any complicated installation, it is literally plug-and-play. The only downside for now is with wire management inside the buffer tube to make room for it. I am not sure if there is enough space for guns other than an M4 but maybe you can find creative ways to fit it e.g. longer wires. This can potentially benefit rental fleets because it is the easiest upgrade possible with zero overhead on tech, plus it makes your NiMH or LiPo inventory much safer and longer lasting. The savings in overhead for battery management could be worth the investment. And when a gun dies you can very easily transplant it to the replacement gun. In theory, you can actually stack multiple units for extra performance (the only problem is finding the space to put them). Conclusion is, and I am probably biased, supercaps could be the next best thing in airsoft. If the space problem can be resolved. Please do comment if you spot any issues in the theory or in the blueprint. Thank you for reading.

-

What would the most "function over form" AEG look like?

Pseudotectonic replied to Herrgh's topic in Electric Guns

If you are talking about AEGs specifically, you are really talking about an M4 without the appearance of an M4 If you take all the functional parts out and put it back together, it would still look somewhat like an M4 You can go crazy with the design of the externals, you can even do one of those 3d printed guns like https://github.com/HYBRIDAIRSOFT/MOSQUITO But in essence, it will be an M4, because an M4 is close to being the most practical AEG you can get considering the parts available If you have unlimited budget and designing the whole mechanism from zero, of course that is another topic -

I don't see the point of mixing bushing and bearings because as per airsoft physics, the differences and variables affecting the three gears do not make them considerably different from one another in terms of the type of loading and the amount of force behind them The different surface finish on the axles themselves with different gears already makes it impossible to work out the precise newtons applying on a bearing because if it is anything but perfect it is going to have a bit of wobble, and the brand of bearing alone (and the size, and the amount and type of grease, heck even the amount of dust exposed) will determine your shock load capacity of the bearing which is what ultimately makes using bearing worth while for the speed advantage But since every particular setup is different, even the best bearings you can find will have a risk of exploding, again because of airsoft physics and tolerances If you have to be mathematical, the bevel gear spins the most, followed by spur and sector gear, so the bevel gear will benefit the most from the less resistance from a bearing, in theory, but if you are willing to take the risk of exploding bearings there is no reason to not use it on all three gears So it comes down to whether your setup is so marginal that your motor and battery cannot handle the negligible amount of extra resistance from bushings that you have to sneak in one or two or three bearings to lower the resistance, and choosing how many bearings to use is just a matter of risk management, because more bearings = more points of failure In my opinion, bushings work fine, they are more reliable, the speed difference is not worth the risks of failing bearings because they fail catastrophically in almost all cases If you want to put in bearings, I would start with putting on the bevel gear first, then spur, then sector gear, but in reality it does not matter because again, airsoft physics and tolerances is a pure chaotic mess therefore there is no theorycrafting possible, in reality it might even come down to the finishes of your particular gearbox and whether your shimming is making one of the gears rubbing on any one of the bearings, for example, so again, no theorycrafting is possible, because it is ultimately up to you and two million other variables

-

Yes you can still play with it without UKARA The question is only related to how you got it in the first place The only legal route would be she give it to you as a gift But after you got it, you can go to a field and play with it no problem

-

DDM4 PDW pictured with a light and red dot it's the DD pistol grip that gave it away