Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

Sewdhull

Members-

Posts

591 -

Joined

-

Last visited

-

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Sewdhull

-

Do you have specs of the motors you'll be stocking?

-

It's training, using cover moving, shooting etc. It doesn't need to be realistic if the drills apply in real situations. All training is like that until you want to do it under pressure and see if the drills have stuck.

-

Yes I have one of those, it is fine and cheap. Match the solder to the iron and it is fine for connectors, 60/40 lead tin or if you can find it 63/37.

-

What brand BBs are best nowadays? Bang for buck.

Sewdhull replied to Alex34's topic in General Discussion

That's an interesting graph, but man it's hard to read. -

Put a deans on the gun... bend the middle wire back remove the bare conductor bit and heat shrink it to one of the others. Connect the other two to the Deans From the above it looks like the single of the 3 connectors is the positive. Should be able to confirm from the battery you have..

-

The benefit of HPA is that the pressure doesn't drop (marginal drop) as gas is used in a shot and has less cooling ( no phase change). Both of these things create better consistency. If the pressure remains constant vs propane for example where the gas gets used up and pressure reduces in a shot, you will have more gas per shot for HPA. In a gas pistol, the rocket valve will limit the gas to the bb (its not really regulating it), then the rest of the gas operates the BBU. My understanding is that the rocket valve will close when the pressure behind is rises high enough, that this happens when the bb leaves the barrel and the pressure on the forward side of the rocket valve is released so it is pushed closed and if there is enough gas left over cycles the pistol for the next shot. If the barrel is longer this will use more gas, and get more energy to the bb. With propane the amount of gas per shot is limited ( the pressure takes time to be raised again within the magazine) but with HPA you aren't limited by gas volume and can extend your barrel and get more energy into the bb.

-

What brand BBs are best nowadays? Bang for buck.

Sewdhull replied to Alex34's topic in General Discussion

The time to target for the same energy is marginally slower at first and by the time you can notice a difference the heavier bb is quicker. This is the main reason they travel further, higher average speed. This is because of physics. From the airsoft trajectory project. -

Whilst the 101 is fine for electronics and portable soldering, for cabling and power connectors something with a bigger heat reservoir works better. Expensive too, same for Hakko. Only you will know you needs.

-

I have put the gearbox back together and test fired it and all seems to work nicely. I have the ak2m4 motor 22tpa and 13:1 gears, fettled the box and set up the Perun hybrid. Very easy and intuitive once you understand the speed you need to flip auto and single fire back and forth. I had no issues with the Perun, all worked as it should, I kept the manual safety so that the selector plate has some spring tension on it still ( the Perun removes the selector lever and therefore the plate spring ) I had previously fettled the selector plate etc to get smooth fire mode selection. I have the std spring in at the moment, 11.1v lipo and the std setting for the Perun has braking on at 3 iirc, so I took it to zero, added 3 round burst on auto and played with the pre cocking. As it turns out, with no braking and no pre cocking, 3 round burst pre cocks it nicely to the rear. In single fire I needed pre cocking to 3 and braking off. pre cocking 4 gave me a 2 round burst, I'm trying not to use braking as I can feel the motor heating even with these settings and I am thinking a 7.4v lipo might be a better option as the rof sounds more than I'm after. I was thinking the motor might be slower than it is ( but it's not), so lower voltage seems like a good shout. Maybe I should have gone with the 28TPA... Hurry up with the brushless AK. I have still to live fire the gun, check feeding and probably have to fiddle with the settings once there's a bit of back pressure and measure the fps. I intend to swap out the the spring with others that I have and see how they relate. Then it's barrel and hop time. I have put the box together with a minimum of lube, the Perun uses optical sensors which I don't want greasy and it looks like a greasy sector gear would contaminate the sensors. I will strip it down after using it a while to see how the parts are working together. The pinion to bevel alignment looks good with grease on the right bits of the bevel. Many shims aren't flat when they are made (they re stamped and end up a bit curved) so all the shims I used i flattened on a block so they sit flat, I'll check those in due course. The wiring goes to the rear now and I have a solid stock to replace the sliding one that came with the gun. A few of the fettling mods, Shimmed the motor tower to remove play into the gearbox. Brass tube Shimmed the hop unit to remove play into the gearbox. Brass tube ( a ring really) Reprofiled the selector plate and rounded the grub screw on the right side of the selector as it was rubbing on the handgrip. Added xt30 connectors instead of the Deans. Used a thinner wire tappet plate spring, for ak2m4, the original was verrry stiff. The Perun wiring is 18AWG which I may well change if I feel the need. I have some 14,15 and 16 Teflon cable so i can choose. There are pads on the Perun to add cables for a tracer should I feel the need. I'd add a couple of LEDs to the hop unit if I did that. Already have some in the parts box. I modded the feed tube to my g36 with an )O ring to stop the bbs dropping out, I may do this to the MP5, ill see what the timings are like but its not high on the list. I've got some buckings to try and the silencer to fiddle with once I am firing bbs.

-

Clip the reds together and stand back, ot the deans

-

If it's dead it's damaged, chuck it.

-

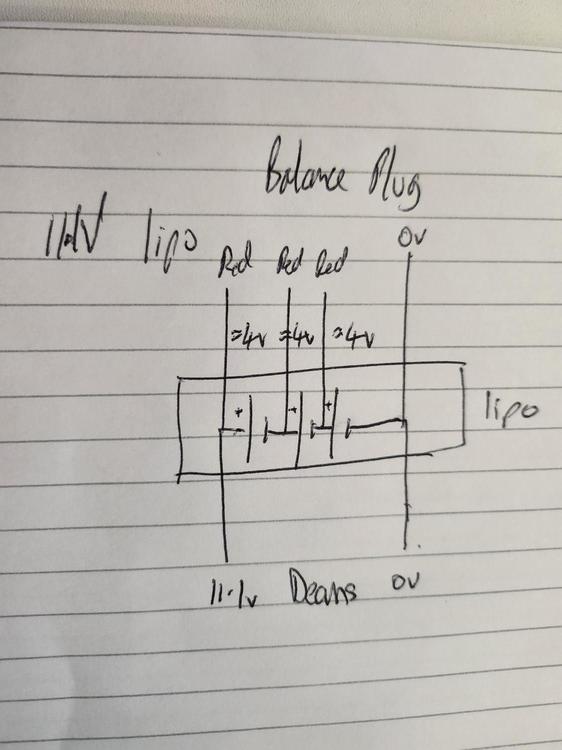

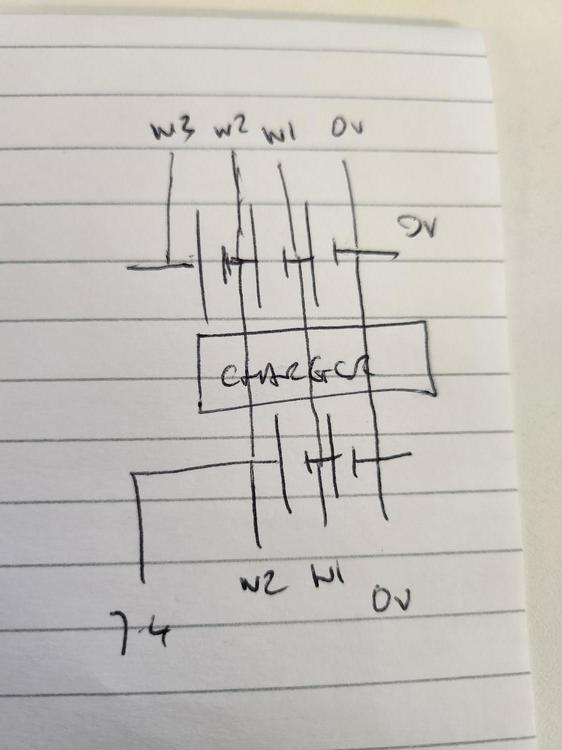

Yes the reds are on the positive of each cell. So one red will be the pos of cell 1 4v with ref to 0v The reds between cell 1 POS and cell 2 pos will be across cell 2. The reds between cell 2 pos and cell 3 pos will across cell 3. You can measure cell voltages in this manner. Most of my packs have different colours for balance wires

-

-

The red wires have a voltage relative to each other. The voltages you are measuring are cumulative. Measure between each red. The 4v red is cell 1. One of the red to red connections will be 0v

-

I'm assuming you are using a meter to measure those. I'm sure you can see the anomaly there. The lithium's won't be 8v. There is chemistry than prevents it. It's possible that the balance wires are screwed up because that looks like 4 + 4+ 0 and it's being measured cumulatively. The balance wires, 4 of them for 3s will have, from 0v, 4 8 12v on each wire moving from 0v. 0v to wire 1, 4v Wire 1 to wire 2 4v Wire 2 to wire 3 4v 0v to wire 3 12v. Apologises if I'm teaching you to suck eggs, but the numbers aren't right.

-

I don't see how a lithium cell can be 8v. It may be that the charger balancing resistors or other bits are damaged and the voltages are being incorrectly reported. What's the voltage of the whole pack?

-

I would suggest you would not have issues, altho a different rocket valve might assist if you do. Lower pressure might work for you in a longer barrel as the rocket valve will be slower to seal, but I have no experience of HPA, so maybe others will chip in. The valve on the magazine is held open while the action cycles, it's the rocket valve that allows gas to the bb, affecting gas pressure to the bb and consistency, more pressure creates more flow and depending on the design of the rocket valve that determines the pressure and gas flow . Once the magazine valve is open the pressure is released as far as the valve is concerned ( it's similar both sides of the valve) so I don't think pressure affects the valve opening, but will affect the flow rate, esp HPA. With hpa you have as much gas as you want so you can get lots of joule creep with longer barrels, with propane etc you are reliant on the liquid boiling off to maintain pressure as the gas is used so you can run out of gas in a shot, but ready to go for the next. Great description of GBB operation follows,

-

I don't think you can rule out the battery. When stalled the battery should be pulling as many amps as it ever can and 10A is no where near enough under load, my motor needed 5A just to start turning... You say the motor spins. Is this out of the gearbox? Is the commutator coppery or black. There are switch contacts and the copper parts on the selector plate which can corrode over time and use. Either you have too many high resistance parts in the wiring, or the battery current capacity is insufficient. You might want to give it a bit of a service anyway after 22 years...

-

pic please? is it the plastic that has broken? A 24hr cure jb weld or araldite will be the strongest, the 'plastic' ones may have better adhesion but its hard to know what you need without seeing the broken bit.

-

You charged a 3S lipo? And killed a cell you think? What's the voltageof the pack, not measured on the balance connector. With a meter, not the charger.

-

High currents can stress etus, some never had great MOSFETs, but also low tpa, poor magnets don't give you great braking, you need TPA to give you braking effort and low tpa give the braking more to do...

-

Yes hard braking will be worse for the motor than softer. Running any brake also means there's less time for the motor to cool between instances of running. Because motors are enclosed cooling can be an issue anyway. Brushes have a hard time as well as the armature windings. Most neodymium magnets will permanently lose magnetic strength(even after they have cooled again) if they get near 80C which will increase the current the motors run at, because the back EMF which limits voltage will reduce and therefore current will increase at the same revs making the motors heat up even quicker. Once the motor is out of its design parameters it will go south quickly. Ferrite magnets tolerate around 3 times that temp. The best setting is none, but if you need it, the weakest braking is the next best. Even in the cold the motor can get very warm in use as your hand tends to warm up the grip limiting heat transfer away from the grip, which has poor thermal transfer from the motor because it's surrounded by air anyway. Not running your motor hard is the key to motor longevity I think.

-

Yes, it's really hard to get it back tho, so I normally get another one already filled with smoke Omg. Airsoft eh? Make it your avatar pic You can probably thank TM for the polarity issue...

-

https://www.airsoftcentral.co.uk/search/for/Warhead/ 104gbp

-

Braking a brushed motor creates at least as much damage as running it. Voltages will be higher (limited by the speed the magnetic field collapses at) and you are effectively shorting the motor for varying periods of time(MOSFET switching on and off) and that energy all turns into heat. Brushes don't like it either. Higher torque motors suffer more since they produce more braking torque.