Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

Sewdhull

Members-

Posts

591 -

Joined

-

Last visited

-

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Sewdhull

-

I have a well l96, which has been fine, I haven't used it for years now tho. Most of what needed doing was DIY, with some trigger parts bought in steel and some reinforcement of the cylinder. I improved the tolerances on the hop and the gun generally and it was pretty good out to 70m, the length of my testing field. In game ppl were never that far away so it became pointless, you need the right field for sniping. Back then the heaviest bbs generally available were .4 or 45. I enjoyed the gun. Probably one of the cheapest I've had and I like cheap guns.

-

Army Armament R34 light striking with WE Mags?

Sewdhull replied to The_Lord_Poncho's topic in Gas Guns

My we gas mag for the big bird has a valve that sits at the same height as the back of the mag. If your mags have different valve heights they will be struck differently by the striker, perhaps not sufficiently to work properly. You should be able to see if this is the case as well as how the exit rubber bit sits compared to your known good mag by close inspection. -

Army Armament R34 light striking with WE Mags?

Sewdhull replied to The_Lord_Poncho's topic in Gas Guns

Dimensionally are the 2 mags the same, in respect of the outlet valve area. Pics maybe? -

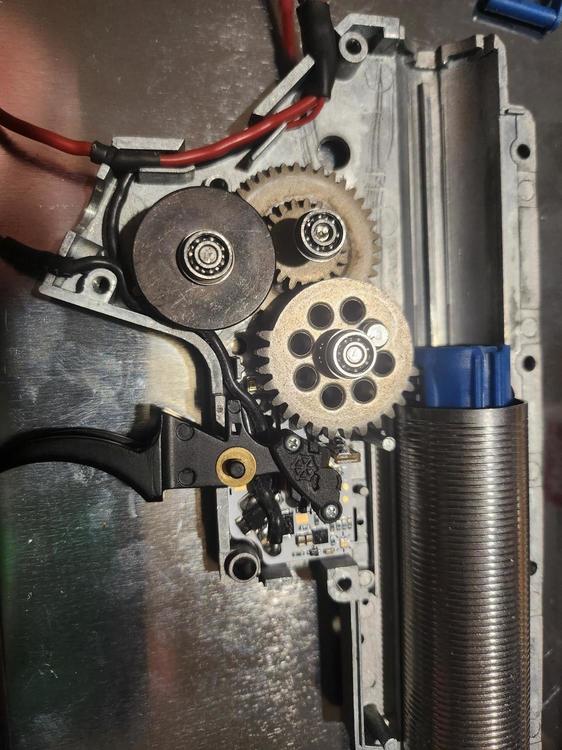

Did the shimming and finished off the perun tasks today. On this gearbox I removed the trigger screw protrusion with a drill bit instead of grinding stuff. The cutoff lever is removed with this perun hybrid. All the scratches are from the manufacturer. The perun sticker I applied after removing the copper and cleaning the plastic with isopropanol. The bearings are 3x8x3 and I had to widen the channel in the selector plate at the top in this pic to take some pressure off the plate so it moves without much effort. Even with 2.5mm ones in the plate rubbed Bearings are from ak2m4, run nicely with thier 7 balls. Obviously better than 6... When I'm finished opening the box I'll lube everything, seems I have a leaky nozzle, the blue, apparently 3d printed, one that came with gun has a texture on it, no o ring and a very strong tappet plate spring which I'll have to compare with some others before I'm happy.

-

It's just 10mins to cut and prep the tube, it's half a mil wall thickness. Can't use a pipe cutter cos the cut piece is too short.

-

Yes, for this type of thing on thin tube I'll use a drill to hold the tube and a file to cut the tube itself, just put it on the tube in the right spot, let it make groove and then file it as the tube revolves. Once you have a decent groove you can use a sawblade, then back to the file to finish it off. Deburr and it's ready. I make it an interference fit, heat the tube and drop it on. If the tube has a bigger OD than needed, reduce that with wet and dry in a spinning drill before cutting. This one didn't need it. Or you can ream the opening to fit the tube, a 10mm reamer works but all this depends on how much gap you have to start with. A bearing in the thin end would be nice but this tower doesn't have one. The tolerances for some parts are really poor I have found in Airsoft.

-

The piston heads I've seen don't seal so much as restrict the airflow out of the cylinder head, perhaps aoe is unaffected or only if there is insufficient time for the air to escape. I recall calculating an unrestricted cylinder taking 1ms to travel 70mm with an 80N spring. If there's not much sound reduction it's likely the piston head still reaches the cylinder head but at a lower speed. I take on board the issues with bounce and aoe It's a layer of air under pressure and 300mph seems a little high ?, but it's the energy that matters anyway. I'll do some sums, I know you guys love sums

-

Anyone used these at all? I see they have been used successfully to reduce some noise, they also look to be likely to reduce the shock forces in the gearbox. I realise they may make no difference at all to anything but I find it interesting so any experiences would be welcome.

-

I thought everyone would make it so thier motor stayed in one place whilst in use. Seems pointless shimming your gears and then let your pinion flail about as it rides the bevel because the motor isn't fixed to anything or slotted snugly into anything. Some might be lucky with tower gearbox fit ment. I had a mil play. I used .5mm wall brass tube as a shim.

-

Propane butane mix is the ultrair buff coloured bottle

-

Oh, you have an adjustable valve...I take it your experience of propane or the propane butane mix hasn't been successful at that sort of temp?

-

The we big bird seems to have a fixed inner barrel altho not terribly well fixed. I added o rings to better locate it when in battery. My KSC or kwa Glock 17 has a tilting inner barrel.

-

Yes. Every gas cylinder should have that. Thank you. Find out what pressure your gun likes and then adjust your gas to suit.

-

That's a useful thing to have on the gas for comparison. The actual pressure I think will an atmosphere less as pressures are usually quoted with refence to a vacuum. Anyone have the lil chart for green gas?

-

Are you looking to lose BB energy for any reason? If not keep the same length.

-

As in disproportionate to the delivery device. With no slide and just a bolt it cycles quickly, never mind when ppl use lighter bolts and stronger springs. Semi auto can be plenty fast enough, full auto is disappointing. If you don't mind everything being all over quickly then it's fine.

-

That's some pressure... I presume its absolute pressure, propane is 135 psia.

-

There's a lot of cool down on full auto, it's a small mag and the fire rate is silly.

-

The aap is pretty good, fine in std form if you don't go full auto. Better buckings are always a good idea. Most of the noise is the nozzle and bolt hitting things

-

Need a spade connector.... what size, and where from?

Sewdhull replied to RostokMcSpoons's topic in Electric Guns

The ratcheting one from 12v planet is great -

Need a spade connector.... what size, and where from?

Sewdhull replied to RostokMcSpoons's topic in Electric Guns

You are crimping to get an electrical connection so you need to fully compress the wire inside the crimp so there are no gaps, deforming the wire and providing as much contact as possible with the connector. Folding the tabs over rarely provides this. There are crimpers for insulated and non insulated wires. The Screwfix one there is for insulated terminals. The eBay one is fine. This page shows a range of tools. https://www.12voltplanet.co.uk/cable-termination.html You can see how small the gap is on the crimping tool jaws. https://www.12voltplanet.co.uk/non-insulated-terminal-crimping-tool-standard-duty.html That crimper will do, altho I have the 40 quid one or similar. The ratcheting helps alot. Wire thickness will affect the size and quality of your crimp. 16awg wire is the largest that will fit a 2.8mm terminal usually, which is the largest guage you'll see in Airsoft. My perun doesn't even have that... Cheapest is soldering the wire having lightly crimped with pliers and then crimping the insulation in the strain relief part of the connector. Bend it beforehand if you'll be bending it. -

Need a spade connector.... what size, and where from?

Sewdhull replied to RostokMcSpoons's topic in Electric Guns

Take the plunge...go on -

Need a spade connector.... what size, and where from?

Sewdhull replied to RostokMcSpoons's topic in Electric Guns

-

The MOSFET has 2 extra wires otherwise it's the same as the Airsoft one. The motor is unlikely to be too strong, the effort in the gearbox is dictated by the spring. Isn't it possible the bevel gear was damaged when the nozzle hit the mag knob thing and the gearbox locked up? It doesn't sound like they have been diligent but the timeline is a bit confusing for me.