-

Posts

523 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by paradoxum

-

I did a better video: so as far as I can tell the actual board with the plugs is completely fine, so the problem must be elsewhere further down the line, and that balance connector board won't help at all.

-

Alright, I'll get that if I can't fix this + the balance breakout board thing doesn't work (Don't have high hopes but could still be useful with any charger). I recorded a video of me testing the continuity with all the pins, can someone check it looks good?

-

I just found a video on that and was about to check them:

-

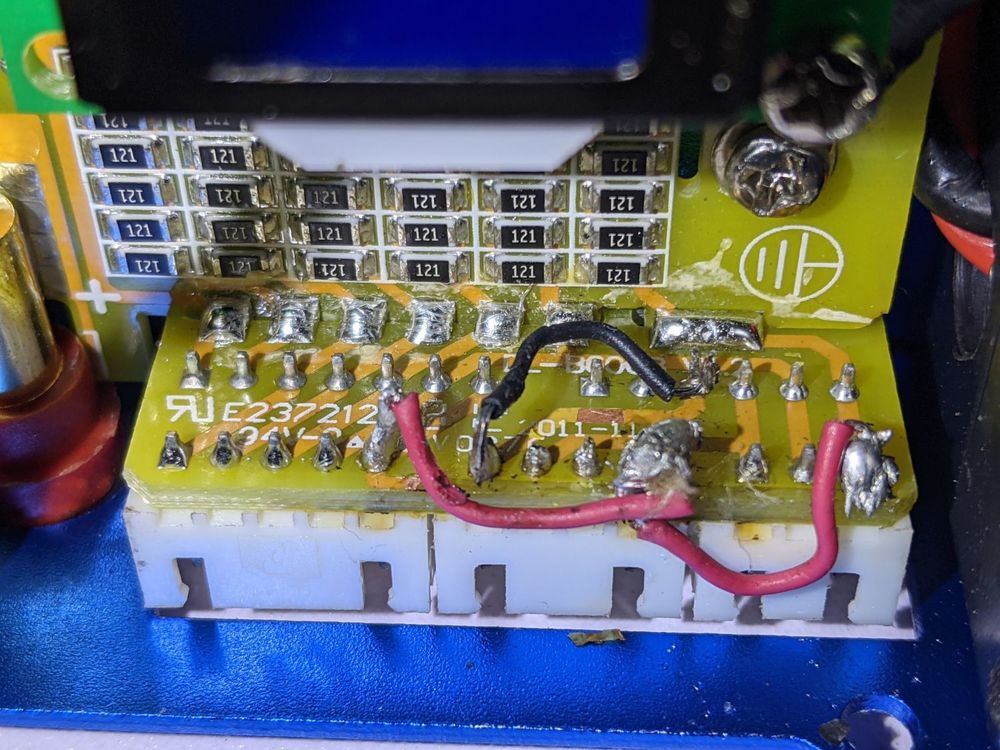

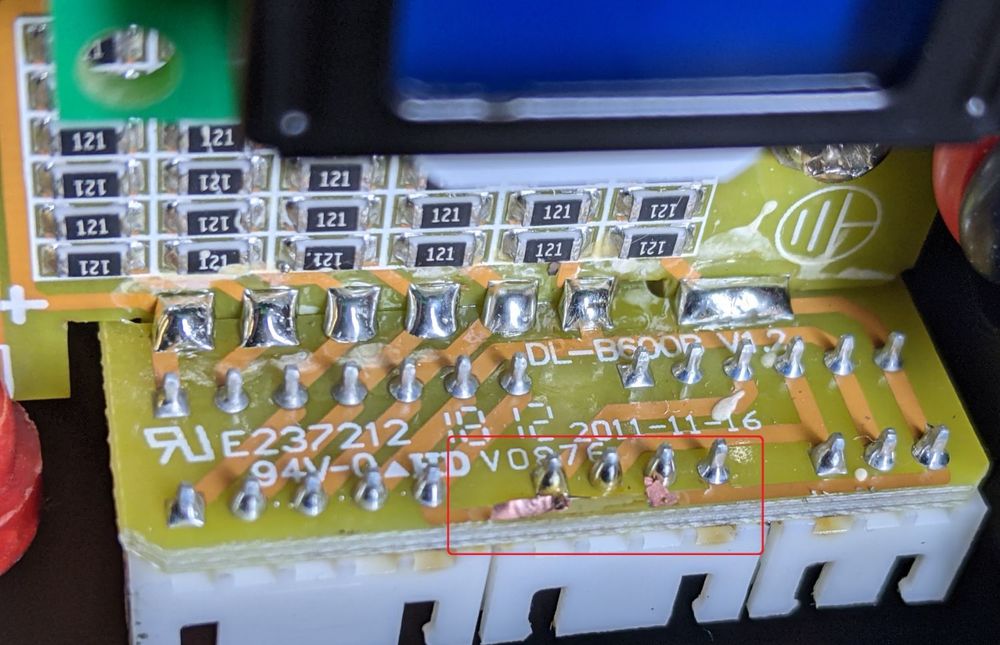

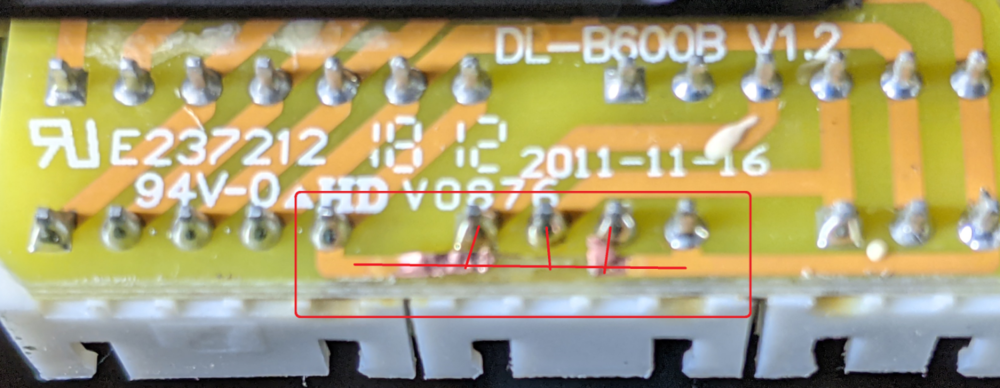

Thing is, the amount of money I spend on my guns, I'm not gona skimp when it comes to a lipo charger when they're "only" £60 (yes expensive but I see it as an investment, and well, this has been running great for like 3 years until I fubard it. If I wanted to get a new charger but a really high-end one with extra testing suites etc (planning to get a whole electronics setup with oscilloscope and everything for fine-tune testing things) any brands or ones I should look for? The higher priced ones seem to just mostly have multiple charging outlets rather than any additional features from what I can tell, and while being able to charge two at a time would be good I'd never need 4+. This is what it looks like now. I cleaned it up with iso alch and made sure there was no leftover trace or bits of solder anywhere. I burnt another trace myself by accident so I fixed that too. It was pretty easy actually. I know it looks a mess, but it all checks out with a multimeter from the pins on the 'outside' to the 6+1 solder points going from the smaller PCB to the large main one. I'll just paste what I posted on rcgroups forums asking for help:

-

There's no way I'm gonna skimp on a lipo charger of all things. Whole reason I got a legit IMAX to begin with. I can get one of those boards for about £5.50 on ebay. I'll try that and see if I can get balance charging working with it. Thing is, I went through every single pin / connection from the small pcb to the main one, and I have continuity in all the expecpted places, and there's no visible damage anywhere else - it was literally a split second as the wire fell down and grazed the connector pins - I doubt it did any more damage than the trace right next to it. There's an electronics store around the corner I can take it to, maybe I'm doing something dumb. I did find this though: https://www.rcgroups.com/forums/showthread.php?2664873-iMAX-B6AC-v2-balance-connect-error Which seems to be basically the same problem but caused somehow else. Started looking at different chargers anyway. How about this one? https://www.banggood.com/Charsoon-Antimatter-250W-10A-ACDC-Balance-Charger-Discharger-For-LiPoNiCdPB-Battery-p-1068233.html?cur_warehouse=CN&rmmds=search

-

Well I did as much as I could and the continuity all checks out but still can't see cell2. I just turned off balance in the settings now I can charge lipos for the time being. I found this thing: https://www.amazon.co.uk/Parallel-Charging-Board-Battery-Charger/dp/B07BSHN8T2 It seems to plug into a difference balance connector on the imax, perhaps this would get around the issue and work?

-

Well I had a go. I soldered two of the points between the burnt trace, checked for continuity, all good. Still not working: https://streamable.com/s6r7nv Not sure what else to try. And cheap? They are like £60! Seems to be an issue detecting Cell2. Any ideas? I checked under the board and there's no blown things there.

-

Long story short I shorted the balance connector on my imax, took it apart and I've blown the trace on it. Is this how it should look? Or does it skip the middle one (by the looks of it?) If anyone has one and can help just take the screws off the side panels and slide it out, take a picture of that part for me? Any tips for fixing myself?

-

The 'What have you just bought' Thread

paradoxum replied to Cameron364's topic in Guns, Gear & Loadouts

Yeah iI needed something small enough that would fit in the stock, still need to dremel out some of the inside though. https://www.modelsport.co.uk/product/spektrum-2200mah-3s-11.1v-100c-smart-lipo-battery-ic3-443852 -

The 'What have you just bought' Thread

paradoxum replied to Cameron364's topic in Guns, Gear & Loadouts

New battery came: Excited to see what RPS I can get with this + a titan which should be here thursday hopefully. -

Some more glamour shots: Pretty much 100% complete on the outside now unless anyone has any suggestions.

-

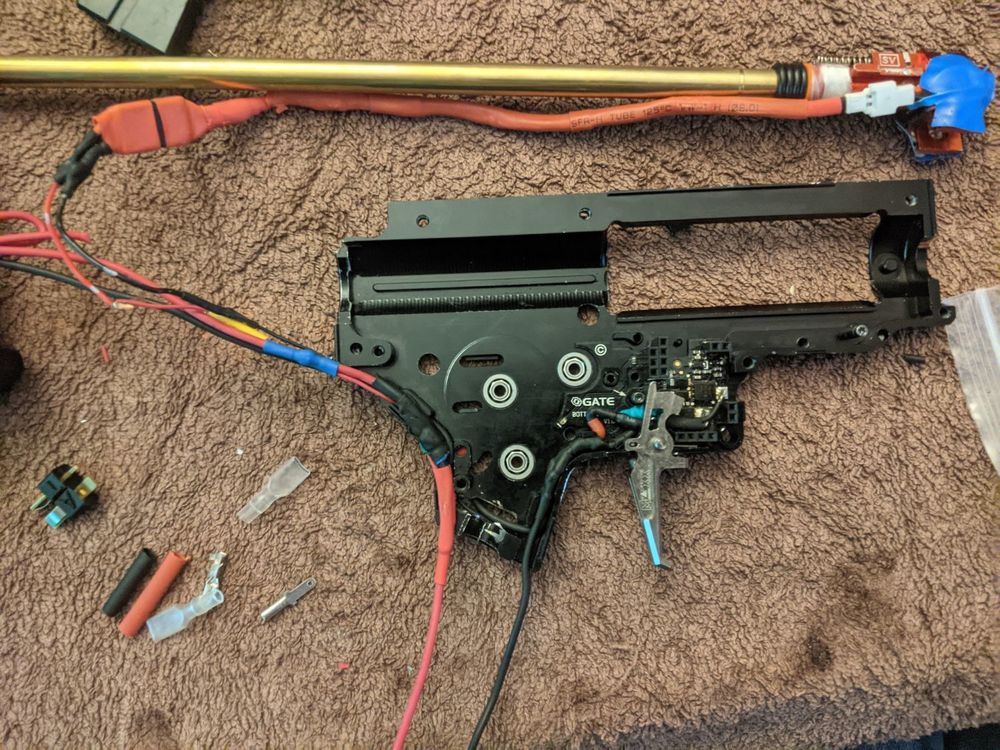

Pretty much complete, my basically scratch-built custom gun, the Orion: I'm getting a titan and dremelling the GB to fit it in there so I can get it over 35 RPS.

-

The 'What have you just bought' Thread

paradoxum replied to Cameron364's topic in Guns, Gear & Loadouts

Nice did he do that? I was thinking of going for something like this on my new build: This is what I have as a base: Thinking of getting a PDW9 stock, getting it cerakoted like that pic, but with touches of gold, like the MPX in the new matrix: What d'you guys think? -

The 'What have you just bought' Thread

paradoxum replied to Cameron364's topic in Guns, Gear & Loadouts

Lots of parts came back from Supreme Coatings today, can get my scarh, orion, and half my new build started. Here's what the ACR stock looks like with the black cheek rest: -

-

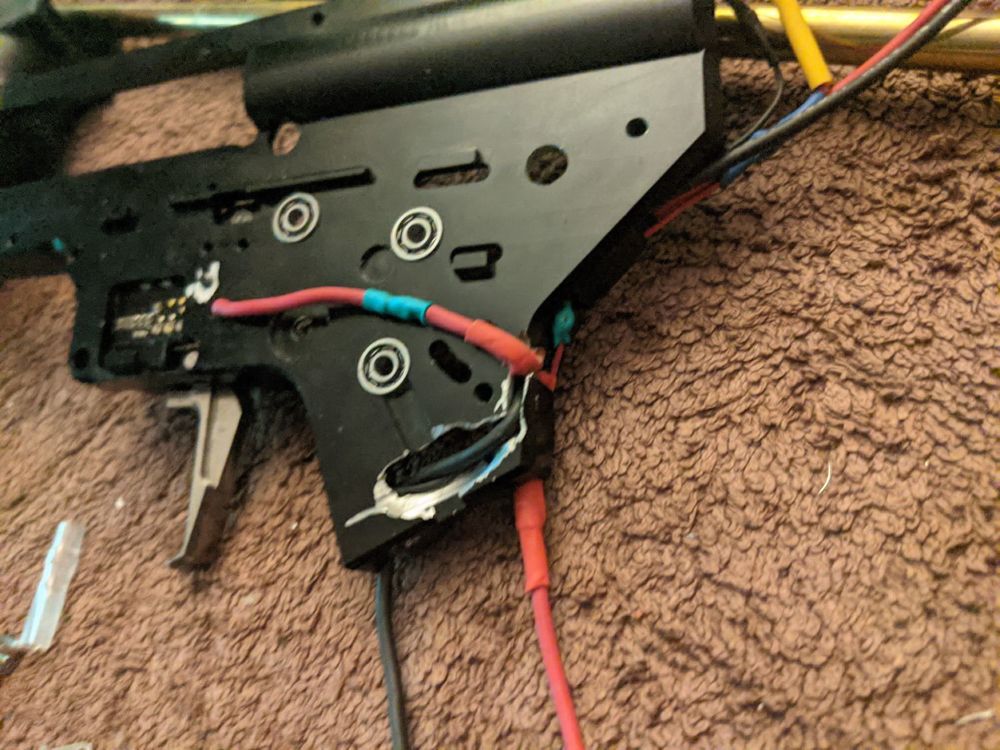

Working on this; put some nylon sheath over the wires so the stock can retract back and forth nicely.

-

I like to keep it handy, cocks, for close encounters. Edit: also, dope guns.

-

Like I said, I've cut the titan wires back to the board and I'm going to rewire it nice and clean when the new wire comes in. I'm committed to the maxx tracer at this point, I took a dremel to my RA GB. nowhere for another battery, plus being wired to the motor before the trigger means it only turns on when you pull it. I have no doubt this wouldn't be an issue with any other gun that isn't a SCAR, there is just no room for those 24g sensor wires without causing fitment issues. I bought an Acetech Lighter BT Tracer unit for my Orion Can't wait to get it setup and shooting red tracers.

-

does this count?

-

The 16awg and being 2mm OD is basically what I needed, because it was impossible to not have my pinion gear shred my wires - wiring the maxx hopup tracer unit into it just took up too much space, I ended up taking a dremel to my retroarms GB and cutting some space: The wiring ended up being a total mess because I was trying to save what little EcoWire I had left, I've since chopped the titan down to short wires to re-do it. But basically I threaded the positive wire from the titan around the outside of the GB so it doesn't have to cross the gap under the pinion. I had to do this, because you need to wire the tracer into the battery wires before the trigger, and if you route them outside of the GB, one of them will stop the grip from fitting properly against the GB, if you try to fit them all inside, there just isn't enough room under the 'lip' below the pinion gear, which results in shredded wire sheathing and shorts.

-

NOW I see somewhere has it in stock here.. Oh well, I'm gonna make the 14awg fit so I can get maximum brrrt with my DSG.

-

I decided to pick up 4 meters of 14awg and 16awg wire, the 14awg is 3.6mm O/D, but with the modifications I've made to my GB I should be able to actually use it - get a full 32amps through it. https://www.ebay.co.uk/itm/361296232202?var=630634243754

-

Messing around; https://streamable.com/5326f6

-

I've been using EcoWire Plus; Alpha Wire EcoWire® Plus Hook-Up Wire Alpha Wire EcoWire® Plus Hook-Up Wire is 100% recyclable, halogen-free wire that resists hazardous fluids, has a -40°C to +110°C temperature range, and is ideal for industrial applications. This wire is up to 15% lighter and up to 30% smaller diameter than polyethylene (XLPE) hook-up wire. Alpha Wire EcoWire Plus wire is insulated with modified polyphenylene ether (mPPE) thermoplastic and does not contain heavy metal pigments. This mPPE-based insulation helps manufacturers meet WEEE requirements. This 300V wire is available in 28AWG to 10AWG, suitable for ISO 6722, and is RoHS, REACH, and CE compliant. https://www.mouser.co.uk/pdfDocs/EcoWireandEcoWirePlusBrochure_web_3-26-14.pdf (page 4) That came with an order from SR in the US, but this stuff is impossible to find here unless you buy in the hundreds of meters - are there any equivelants at 16gauge in terms of thickness here in the UK? Solid core, etc etc.