-

Posts

1118 -

Joined

-

Last visited

-

Days Won

8 -

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Iceni

-

Front element removal tool for optics and camera lenses. Should have the reach and fit for the delta ring, and as an added bonus it'll let you drop the front elements out of your optics so you can make some polcarb inserts to sit over the front element. https://www.amazon.co.uk/Professional-Spanner-Opening-Repairing-Maintanance-default/dp/B07VDY49B1/ref=psdc_1330755031_t4_B08CZ9B5WL There's also a straight version if you think the curved one might cause issues. https://www.amazon.co.uk/Neewer®-Professional-Pointed-Spanner-Repairing/dp/B00J5F6O92/ref=pd_sbs_5/261-4196459-1089624?pd_rd_w=2fzHv&pf_rd_p=c896f142-67ed-468d-b7d2-62dc03d28077&pf_rd_r=75A89WQ7FCKC8Q180XQ3&pd_rd_r=f08a3ced-2cf1-44f8-b12c-3b5e1ef69dd6&pd_rd_wg=oViql&pd_rd_i=B00J5F6O92&psc=1

-

Anyone know of any selector plates that fit with the LCT AK74?

Iceni replied to Sam-Bristol123's topic in Electric Guns

Just buy an original. £8 Fire support. https://www.fire-support.co.uk/product/lct-pk-93-anti-heat-selector-plate-for-ak-series -

Aug's can make good DMR's. Why you would want to do that with a TM HC I have no idea. You have cost - A basic Aug can be had for about £100 new. The TM HC new is at least double that. There is no external difference in quality in a JG and a TM. All of the differences are in the gearbox. TM's are notorious for soft gears that will run forever stock with the slightly lower powered spring... If you stick a big spring in there it's going to eat the gearbox. As soon as you modify the TM HC it's no longer a TM HC, As the only thing that makes them special is the gearbox. For a basic AUG DMR you would want the JG/APS A1 or A2 variant with a full length barrel. Avoid the A3/A4 the ris is heavy and doesn't improve the gun. If you think you want some more rail space look at the APS with the added side rails. If you go with JG you can pretty much just do a spring swap and run on 11.1v to get it running. Perhaps a slightly harder hop rubber. If you go with APS then I'd advise swapping the piston head, Spring and hop rubber and run 11.1v To make it better from there you'll be looking at a motor and perhaps gearing it a little different to get some trigger response. To semi lock it you can do a few things. Tape over the secondary contacts is the fastest and least reliable way to do it, A basic rewire removing the secondary contacts is probably more appropriate and can be done in minutes with a pair of clippers, soldering iron, and some heat-shrink, without opening the gearbox. Inner barrel wise the full length AUG runs a 509mm barrel. So you'll be wanting to run a non ported cylinder and don't really need to mess with the barrel length. The hop is decent enough, been a stock rotary unit, and other than a degrease to make it a little stiffer the unit is solid and not prone to walking. Mags are generally good for the AUG with no real feeding problems even on the cheapest mags. There are loads of 120-170rns midcaps out there that can be had cheap like the battleaxe ones, MAG 170rnd mags are my favourite. https://www.patrolbase.co.uk/army-armament-ku901-steyr-aug-aeg?pv=8463 £109 for the base gun. The Army Armament aug is based on the APS design so it has a raised area on the stock where the textures are. It'll probably want the piston head changing as the APS head is awful with an injection point on the sealing face. Other than that it's a reasonable base gun. For the extras, Your probably looking at Mosfet £20, Head £5, Hop rubber £10, Spring £10. So £45 ish to get it up to DMR basic spec. Add another £40 for a motor in the future when you want more trigger response, but the APS motor should pull an M120 on 11.1v In all it's not a bad basic spec gun for £155ish. As for the DMR role, The Australian and Austrian army both use AUG's in DMR roles. The Australians use a modified A2 style the Austrians use the Hbar-T. To make the Rifle into a Hbar-T the lower hand guard mount can be swapped to a 3D printed lower rail. And a picatinny tripod added. Or you can look for a barrel mounted tripod. https://en.wikipedia.org/wiki/Designated_marksman_rifle

-

When life gives you lemons... converting my AR15 A3 to a DMR

Iceni replied to RostokMcSpoons's topic in Electric Guns

Keep it simple. Buy a second selector plate, Remove a little plastic. With that modification you have a gun that can only select semi. Yes you can move the selector to auto, but it'll still only shoot semi. When you want to go back to a normal Rifle you just put a regular selector plate in and change the main spring. I would used a mosfet with absolutely no features. As a 3rnd burst will still work on a semi only gun. Doing anything more than that is pointless. If you need full auto to clear a trigger jam all you do is split the upper and hold back the COL with a screwdriver. -

If you still have some movement on the Auto contacts then shimming the linkage would be a suitable fix. If the Auto contacts are already as far back as you want then you are going to have to rebend the Front contacts to engage sooner with the dolly. Or build up the dolly with solder to make it longer. If your careful you might be able to take the contacts out without opening the gearbox. Since they just slide in the front and side of the unit from the outside.

-

Yeah give it a go and see where you end up with it. I know on my APS I built it backwards and it was refusing to reset, It would break, but then wouldn't shoot again unless you mashed the trigger a little. I'd have to strip the guns to check, but I wouldn't be surprised if the springs in both guns were bent differently.

-

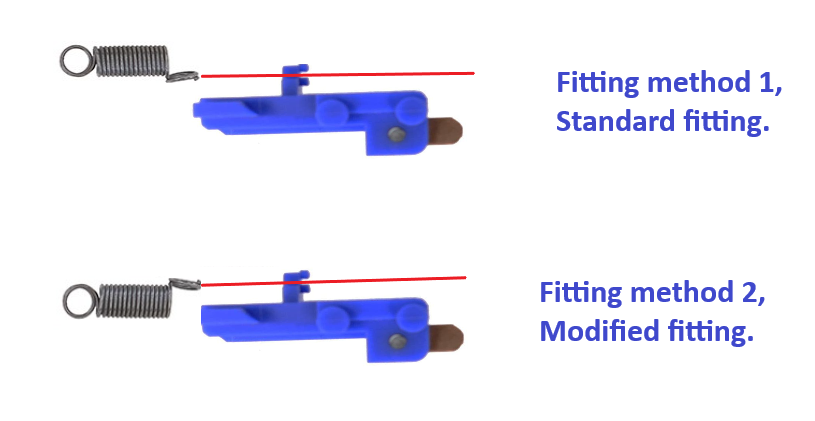

I did mention before about reversing the return spring. Perhaps you didn't quite understand what I meant by that, so I've done you a diagram. My aps aug prefers the second way with the loop at the top, the JG likes it the other way round. The only thing to watch out for is the loop at the other end might look like it's close to the edge, But hopefully your shells are close enough that it can't jump off. It might be worth just giving it a try before you put more money into it.

-

Sorry been at work Yeah definitely the COL/Dolly interaction that's failing. Glad it's not the Mosfet. I'd replace the unit for standard V3 parts. The SHS/RA parts should be fine. But to be sure I'd do the COL and front contacts. That way you rule out wear, and warping on the COL as well. If I had the time I'd say pop over at the weekend and I'd fit it all for you, but we are in the final week before the British retail consortium audit at work, and panic mode in the engineering management is kicking in.

-

My favourite was splitting an AUG at chrono to get a BB out of the body... With a mag in it. It dumped a mid cap. With everyone watching.

-

It shouldn't just push up. It should push up and snap back to the starting position without needing to reset the trigger. On semi auto. So with the tape over the auto contacts - A single full trigger pull - Moves the dolly forwards - It touches the contacts. COL hit's the dolly lifting it over the trigger - dolly snaps back - And it falls back into the reset position with no contacts been touched on some trigger designs it might stay at an angle but it should always snap back. Trigger is released and lifts the dolly and picks up the step that will allow the trigger to be pulled again. If the Mosfet is working on the program trigger, and is working in AUTO then the only fault that can be left is the Semi auto contacts and Dolly. That whole assembly is the same as the AK. So getting a replacement is easy enough if need be. But I don't think this issue is the MOSFET if the program trigger is working as intended, as all that trigger is, is a push switch.

-

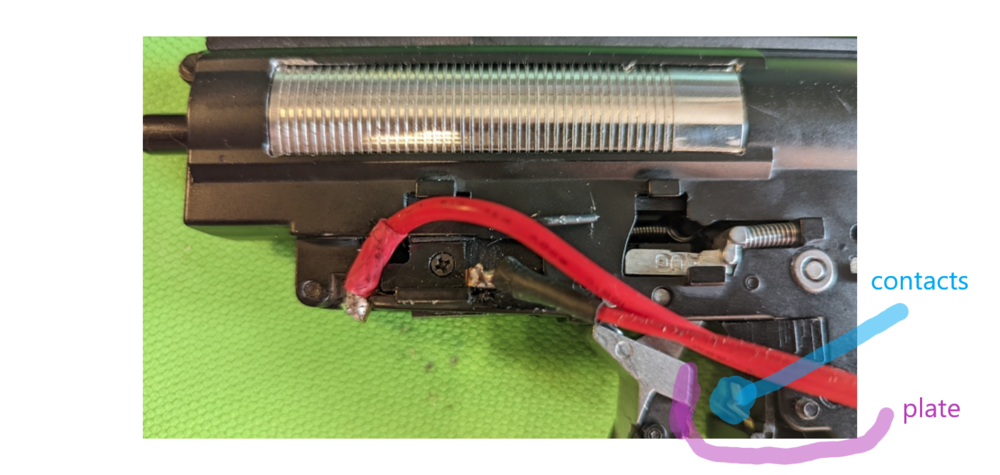

before you do anything. Pop a piece of tape over the plate on the trigger style contact... You may have just lifted the auto fire pins With the tape in place you should just get semi. Provided that works. the next step is to just lower one of the little contacts on the inside of the trigger/auto contacts until semi and auto are separate again. Adjust only 1 pin.

-

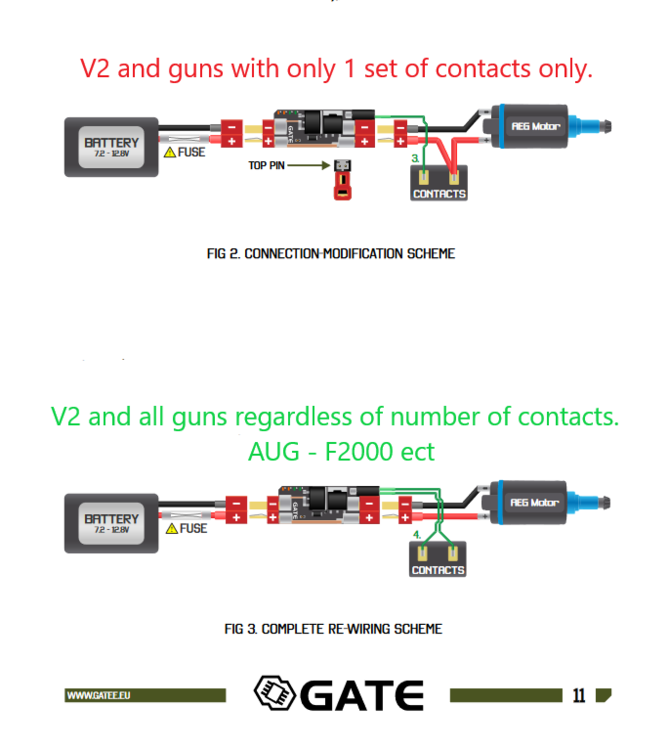

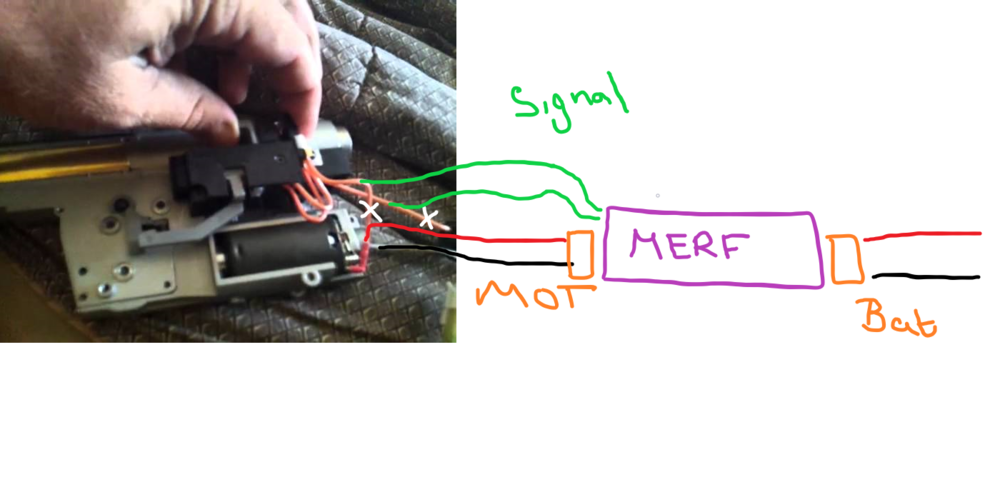

1. Remove signal wire. 2. Move front trigger wire back to original position. 3. Cut the + and - wires as per this diagram. 4. make a decision - You can go with the double signal wire. Solder it to the green area wire tags. Preferred method. Polarity doesn't matter as this circuit is now isolated from the mains. The sensor wire can go any way into the Merf. 4.b. Go with a single wire as per the last diagram I posted above - note you will have to work out how to feed the + side of the trigger. Polarity is important. The feed from the + is essential and the sensor wire has an orientation on the Merf. 5. Connect the deans directly to the motor.

-

She's a shelf queen now!

-

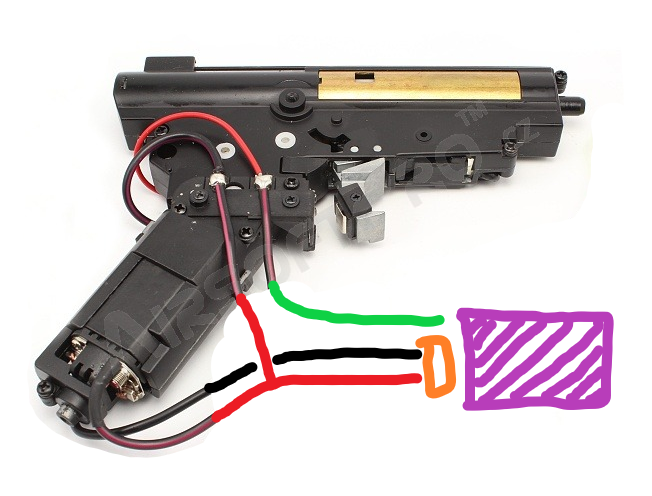

Dude it's the same as the AUG. The single wire system only works when you have a single set of contacts, like a regular V2, V3 (AK). As soon as you have a secondary set of contacts the method I put above is the easiest way. 2 cut's and just run 2 separate loops. It's actually on the same page as the V2 diagram, Under it... Figure 3 page 11 of the manual. You don't need the motor spade connectors. Your putting a deans in and the motor is separate from the loom because of that. So provided you make sure you can get the motor out of the cage with the wires on (you can on an AUG, not sure about the F2000) then you can just solder the wires directly to the motor. Those are pictures I did for another fet but it's the same diagram for the merf. In addition to this you also have to put one of those single shot trigger back to normal. Looking at how you've wired it I don't think you have put any power down the signal wire. But it would only work in single shot, and full auto would cause the Mosfet to power down thinking it had a short circuit. So exactly what you saw. As the single shot trigger would initiate the motor, the full auto contact would be open, but there would be no signal wire signal as the COL would have broken the semi contacts. So it would kind of fall over itself and go safe. A single wire setup would look like this. Had to have a good think as to how it would work.

-

Your wires should look like this. Cut on the white crosses. I think what you've done is use the signal wire to carry full current, hence it shutdown. The diagram above with the double signal wire directly to what is now an isolated contacts circuit. The motor directly to the Deans, as an isolated motor circuit. If it's still working on the program button then you should still be good. There was no need to move any wires at all. Damn I wish you would of just asked for a diagram before you started.

-

Overlander have a near identical one on the website. I would imagine they come from the same place. https://www.overlander.co.uk/2200mah-11-1v-3s-35c-supersport-pro-lipo-battery-deans-connector.html same weight 169g, same capacity, same voltage, same C rating. sizes are also pretty much spot on depending on who did the measuring. 102.25*32*22.9mm 101 x 33 x 23 The only thing I can really see that might be different is the overlander uses 14Awg to the Urgenex's 16Awg (thinner). Would be fair to assume you could pick what wire you wanted if you were ordering in bulk. For airsoft even if the 35C is burst you still end up with a 38.5-77A battery. Well within spec. But I would hope it's the same spec as the overlander with a 35/65C rating 77/143A. Worth a gamble. But perhaps charge them at 0.75C a few times to see if they have any issues. So 1.65A instead of 2.2A.

-

Zci barrel causing misfeeds and jams are mad bull barrels any good

Iceni replied to steverebo's topic in Electric Guns

Spot on it's feeding at least then. Might be a dodgy barrel, Check the window for burrs. And drop a few BB's through the barrel to see if there is a spot where it catches. To inspect the window - have a poke about at the edges see if there is a wire edge that has folded - remove with a small file or sandpaper. Check the corners, harder to repair but a bent square micro file can get into those from the top to just round them out. Clean it with some IPA and give it a decent scrub, might be something sticky in there that's picked up some swarf in manufacture. Or send it back, If you got it from somewhere reputable like AK2M4 I'm sure he'll be more than willing to replace it since it feeds but does not shoot. -

Zci barrel causing misfeeds and jams are mad bull barrels any good

Iceni replied to steverebo's topic in Electric Guns

Whoa guys! The gun is feeding fine on one barrel with the same feed nozzle and hop unit. It's only the barrel change that's causing the issue. Feed nozzles only go into the hop and touch the barrel. Therefore the issue isn't feed nozzle, tappet spring, Midcap syndrome, or hop unit. The issue can only be the barrel. So it's either got an issue like a crushed feed, Or more likely a burr or there's a little too much material on the feed side of the barrel and it's allowing the BB to lock up once it enters the lips but before it enters the barrel. Hence Chamfer it first and rule that out! It is probably that the failing mid caps have a little more upwards pressure, and it's allowing the BB to enter the barrel by rolling on the top of the feed... That position is the one that needs the attention. -

Which Mosfet for my upgraded F2000 (Cyma, v3 gearbox)?

Iceni replied to RostokMcSpoons's topic in Electric Guns

Those Fet's still use Standard contacts and a COL. So the fact it's a 2 stage trigger makes no difference. I've dropped my mates Merf into my AUG with the nano hard, And yes you can just drop them in if the gun is already setup on that system. And all the features work, you just have to retrain the cycle time so the functions work properly. The 3rnd burst uses an internal timer. It times one cycle of the gun then uses that to be able to calculate 3 cycles. Sometimes it'll get it wrong but more often that not there pretty good. I should of mentioned but didn't edit: The merf has the same hard cut off as the Nano hard. so if the battery gets too low it'll just stop shooting. You just have the program it to be on the correct voltage. If it's set at 11.1 and you put a 7.4v in it it'll cut out very quickly - It doesn't sense the battery voltage, it just runs to set parameters. -

It's not worth overthink TBF. I tend to run bushings because they don't collapse. If you are building for performance then we don't have the same demands as the USA market. Less motor loading, less gearbox stress. It is more than possible with the UK 350fps limit to get 25rps with a 7.4v lipo and bushings. 13:1 gears, HT 16TPA motor, S/S 2 teeth on sector, M110 spring or there about. Radius the shells if needed, Grease well and treat it nice and it should run for a very long time without any issues. And it's about all you could ever want from a gun. Where the wear points are on the sector bushing/bearing. I have no idea. It's not as simple a question as it seems. You have a force from the spur, A force from a spring been compressed, and it's rotating. The rotation causes some strange things when it comes to wear points, and I think a degree would probably be needed to work the answer out correctly. My guess would be the wear point is the top of the bearing due to the main load been from the spring - that force wanting to push to 3 o'clock but the precession in the rotation forcing that to be 90 degrees ahead of the applied force. The sector effectively climbs into the load. You then have a torque been applied both by the rotation, the offset spur force, and the offset mass. That torque is going to want to act at the 3 o clock position on the upper bearing and 9 on the lower... So as a rough guess 12 o'clock to 3 o'clock on the lower bearing, but more like 1 o'clock to 4 o'clock on the upper bearing. It's a crazy guess tho, I'd love for someone to do the proper maths on it. It's very very complicated in there. But bushings don't collapse.

-

Which Mosfet for my upgraded F2000 (Cyma, v3 gearbox)?

Iceni replied to RostokMcSpoons's topic in Electric Guns

loads of places have MERF stock at £40. Patrol base, Thecage, bespokeairsoft, surplusstore. Most are £5 delivery. https://www.surplusstore.co.uk/gate-merf-3-2-aeg-mosfet.html -

Zci barrel causing misfeeds and jams are mad bull barrels any good

Iceni replied to steverebo's topic in Electric Guns

Madbull barrel is garbage. I got duped into one years ago, and it was good for about 3 shoots till the coating started to wear out and it would sling BB's all over the place. One thing you should check on the ZCI is the window. They can sometimes have a burr on the inside. If you have access to one a countersink may be the correct tool to just add a little chamfer to the feed end on the barrel. It might make the BB's feed a bit better. You don't want to remove a lot of metal just a skim to give it a little feed angle. The 12mm one in this pack should fit. Pop it in a drill and use a very slow speed and just touch it in, Don't be tempted to go fast - Stainless isn't like other steels and will work harden if you get it hot. https://www.amazon.co.uk/Gasea-Shank-Degree-Chamfering-Countersink/dp/B07GB524J7/ref=sr_1_6?crid=3QOSKIXWGZXJ&keywords=countersink&qid=1643758732&s=diy&sprefix=counter%2Cdiy%2C69&sr=1-6