Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

SSPKali

Members-

Posts

667 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by SSPKali

-

Probably just a Metric thread grub screw, easy to get a packet of them from Ebay or Amazon. Maybe throw a bottle of blue (mid strength) LocTite in the basket too!

-

AG fit and finish seems variable (I am being nice about this) At a minimum swap the piston head (AG one swells and jams up!) and put a dab of super glue on the end of the valve grub screw so if it does unscrew you won't accidentally fire t at someone! Mine has never lost adjustment...YMMV. I would go for the Dynamic Precision bolt and either the TM or DP internals (DP have better springs in the nozzle, probably easier to buy it as a whole kit)

-

Yep, I have a TM M4 and pistol speed loaders and they fill the mags fine, you just get huge thumb muscles ??

-

I have 6 but rarely run them all. In CQB type games I can use 2 - 2.5 in all. I often change mags in a lull in the fighting before they are empty just so I don't get caught out. Woodland games are a bit different, especially on windy days but if you know the limits of the platform it isn't too bad. If you are sensible and only shoot at what you can see / hit 35rds goes a long way.

-

I had a great day yesterday in CQB, big site but small teams so could do sneaky looping back manoeuvres and get the kills in. Managed to shoot through a 4" hole in a door and get a guy in the leg...while I was 7m behind the door, that'll teach him to try and sneak in the back! ? By the last game people were pretty knackered with all the stairs and such but spirits and game play were still top and fair on both sides. Reminded me why I took up this silly sport ? Although my MWS was great, carrying 6 GBBR mags (plus all my other gear) was a silly idea!

-

Just taken out the buffer spring and weight to check the buffer cap screw and add some blue LocTite to it and noticed the end cap that it holds on has a small locator hole on the underside. This looks designed to take some of the stress off the end cap and spread it through the buffer tube stock rail part. No pin or screw fitted (on my 2nd hand MWS) and the Eagle6 tear down video doesn't show it. Maybe a feature TM never used? Because on duster gas it wasn't an issue? I have tried a few screws I have kicking about but nothing that fits. Maybe a future product for SixG Gunsmithing?

-

TM MWSmMags back in stock at FireSupport

-

Take a full speedloader and small can of green gas out on the field with you ?

-

Probably due to play and uneven / offset spring tension causing binding. It is a really weird trigger set up that has lots of places for friction and uneven loading My fix for this was to strip and clean the trigger parts, note where they were burnished and sand them with fine grit wet&dry then rebuild with 0.1mm shims to remove as much play as possible while not causing it to bind. Takes a while to do but much smoother and consistent now. One thing to check is that you are not getting a light strike...The valve knocker isn't moving with the first stage?

-

Probably best to Google that one! Prices in the UK, when they have stock, all seem to be about the same.

-

MWS for sale on here! (Not mine)

-

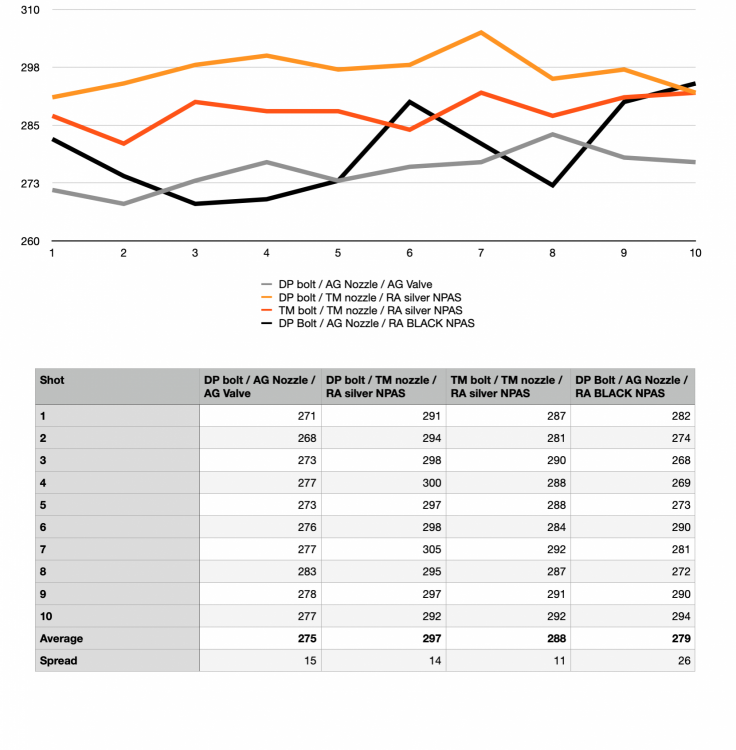

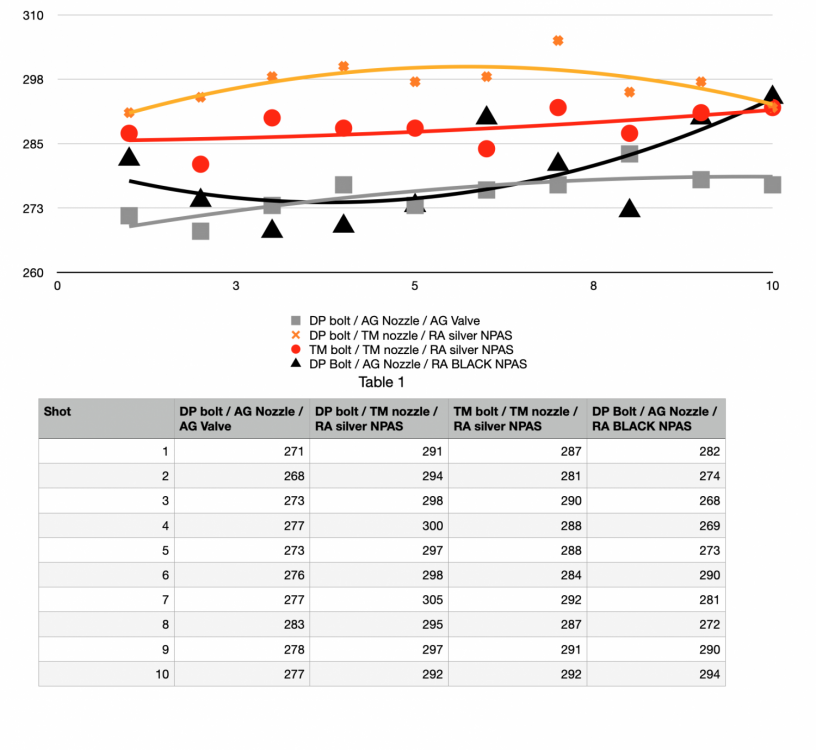

Right, grab a cuppa as this is a long one with charts and graphs! So, having found that my current MWS set up was less than consistent on FPS I decided to play about with the parts I had to find the best (ie most consistent) set up available. Quick Notes: RA Black NPAS - Lose fit in TM nozzle, very lose fit in Angry Gun nozzle (probable source of inconsistency) Requires safety-pin to stop it rotating while using special tool to wind in or out. Hard to see in nozzle when adjusting. Angry Gun adjustable valve - Good fit in Angry Gun nozzle, was too large to fit in TM nozzle. Had a drop of superglue added to rear of grub screw to prevent it unscrewing and flying out the barrel! It was a good tight fit in the screw threads so unlikely. Easy to adjust with allen key, nozzle marked "+ more / - less" on the nozzle to aid adjustment RA Silver NPAS - Had been sanded around circumference to fit smoothly in TM nozzle, was a bit lose in Angry Gun. Easier to see when adjusting it, again it requires safety-pin to stop it rotating while using special tool to wind in or out. Things I did not change: Nuprol Green Gas / v2 MWS magazine, unmodified / 0.28g G&G BBs. Modify Tan Bucking / Laylax hop arm / Crazy Jet 250mm barrel. G&P highspeed buffer / SixG HSB / std recoil spring. Xcoretech X3200 Chrono The weather, sunny 22deg C. All tests conducted out of direct sunlight Dynamic Precision green nozzle cup (moved between test setups) Magazine given a 10s charge, left for 30mins. Given a 4s top-up and left for 5mins between tests What I changed: Initially I used the Dynamic Precision lightweight bolt for tests #1 and #2 Test 1: Angry Gun Nozzle and valve, Dynamic Precision nozzle spring. (GREY plot) Test 2: TM stock nozzle, RA Silver NPAS, Dynamic Precision nozzle spring. (ORANGE plot) Test 3: TM Stock bolt with RA Silver NPAS, Dynamic Precision nozzle spring. (RED plot) Test 4: Dynamic Precision bolt, Angry Gun nozzle, Dynamic Precision nozzle spring, RA Black NPAS (this was conducted a couple of days ago, and kicked off the investigation, otherwise all the same) (BLACK plot) Results: Have a look at the two charts, both have the same data, but the scatter graph has the best-fit line added to aid in looking for the most consistent set up. The setup #3 was the most consistent, but changing to the DP bolt(#2) gave almost the same consistency but slightly higher FPS (maybe more gas efficient?) The one outlier at 305fps spoilt it somewhat so maybe over 20-35rds it might be just as good as #3? The TM bolt, due to the extra weight, gave more recoil, but probably at the expense of gas efficiency. I feel this is an acceptable trade-off as the action was still pretty snappy (thanks in part to the SixG HSB) and full auto was still fast enough. The DP lightweight piston probably saves a little gas and can eke out a few more rounds from a magazine but it will likely be marginal and at the expense of recoil felt (if you want low recoil and high RPS....get an AEG!) Conclusions: The TM Nozzle with the modified RA Silver NPAS seems to be the most consistent, it is likely that the bolt (TM or DP) has little bearing on the outcome in terms of FPS consistency. Recoil and gas efficiency is where these make a difference. The TM Nozzle with the RA Black NPAS (built for the MWS system) is a loser fit and will likely have a wider variance, but not as bad as the larger internal-bore Angry Gun nozzle! (I would guess it would be around the 17-19fps spread...maybe one day I'll check!) So, if you use Angry Gun parts...use the whole thing and don't change out valves/NPAS. Or better yet, if other experiences are to go by, just stick to TM! If you are sticking with TM nozzles try the RA Tech Silver NPAS and spend 5mins with some fine wet&dry carefully sanding the external diameter until it drops in and moves freely. If you can find a Black on that is a suitable alternative...oh and in both cases carry a safety pin in your tool box to adjust it

-

G&P MOE repainted with graphite grey engine paint, Octarms 13" rail and over-barrel carbon fibre moderator. Camo Krylon stripped from the rest of it. Internally I have put in a non-wobbly spring guide and M105 spring (minus 1 coil!) to give me 292fps on 0.28g BBs. Still got the Titan basic and SHS gears. PEQ box for the battery as the MOE handguard was a nightmare and looking a bit old skool. Waiting on BCM rail covers in grey and maybe one of their hand stops if I can find one in the UK as US shops refuse to post due to ITAR regs ?

-

That is really consistent! my RA silver NPAS manages +/- 6fps and after 10 shots it really drops due to mag cool down. Got my AEG +/- 1fps but pretty sure a GBBR won't do that (or need to) Just tested it and on 0.28g it is between 278 and 290fps (one outlier at 294fps, so still under site limit) DP lightweight bolt, AG nozzle, DP springs and the RA NPAS almost all the way closed. Modify Tan bucking hopping 0.32g and a Crazy Jet 250mm barrel. No idea on bore as previous owner installed it.

-

I tried those with my AI propane adaptor and MWS mags....still didn't fill them Gave up and spent the £££ I would have thrown away "solving" the problem buying green gas in bundles

-

I have an airsoft spec one that I don't use (left handed so kept dropping mags when slinging the weapon!) let me see if I can dig it out

-

I had this issue (before I finally tracked down the black one that drops straight in!) All I did was use some fine grit wet&dry and clamping the NPAS in the drill chuck *carefully* sanded it down. Go slow and keep checking the diameter!

-

The 'What have you just bought' Thread

SSPKali replied to Cameron364's topic in Guns, Gear & Loadouts

Internals done, just need to finish weathering the externals. Cyma CM045 Krinkov. -

If you want noisy CQB I would recommend a TM MP7 GBB with a SoundHog on it....sounds like a 22 rimfire when I tested in the garden, will be even louder inside ?

-

Cyma CM045 "Krinkov" Arrived yesterday and I spent today stripping, cleaning and shimming the gearbox (great quality, still with gunky blue grease!) and re-wiring with a 11.1v Li-Ion and Gate NanoHard mosfet Madbull tightbore barrel I had lying around and G&G green rubber / Firefly nub. New O-ring nozzle from AK2M4 arriving tomorrow but not sure I can be arsed to strip it down again ? Outside has been sanded and roughed up, wood sanded and stained. Still more to do on this (and the 5 steel mags!) to give it the true Khyber Pass look. 335fps +/- 4fps and 20rps on full auto ? Destined for OPFOR MILSIMS, loaner gun and noisy CQB!

-

How about this beauty, a thermal rifle scope...pretty cool eh? Asking £500 plus fees and post. Reasonable if it has been cared for... ...then you see the single bolt holding it in the mount. It also looks like a 25mm mount holding a 30mm scope body ???♂️?

-

Anyone tried the TM pistol mag sized speed loader with MWS magazines? I have the TM XL one and it works great but want a small one to carry in the field for those busy games ? I have tried my Nuprol one and only managed to spray BBs all over the floor.

-

The 'What have you just bought' Thread

SSPKali replied to Cameron364's topic in Guns, Gear & Loadouts

Just bought a Cyma CM045 AKS-74U with wood furniture and canvas sling I had the tactical one and it was a beast of a gun (especially with a few upgrades!) and I regret selling it. It easily shot TF guys at the top of the Copehill Down tower (sHoRt bArElLs cAn"T sHoOt fAr dErRp....) and was the best CQB I have used ergonomics wise (don't let my MP7A2 hear that!) Plan is to turn this into a weathered AK as you might find leaning against a shack wall in Afghanistan, but make the performance a little better Internally I have a Gate NanoHARD, G&G Green rubber and some gearbox shims to add, it will be running off a 11.1v LiPo and using steel 125rd mags. The ultimate sleeper gun / bad guy loadout / loaner / backup to my GBBs Next purchase will be ANOTHER gun case ? -

Mine slid on fine with zero play, possibly the finest tollerences I have seen for a while! I added some good quality grease so I have a hope in hell of removing it at some point in the future. You will love the rail covers, if you ordered from Brownells don't expect them to be with you before 2weeks after order, I think Customs / ParcelFarce are a bit busy!

-

The 'What have you just bought' Thread

SSPKali replied to Cameron364's topic in Guns, Gear & Loadouts

No flare and low enough to be below the optic. Only issue is backsplash from the 1200lm! There is a lens holder on it and I have red, blue and green filters to cut down the glare (and protect the lens of the light!) I just need some dark CQB games to see which works best for dazzling the target and IDing them quickly