Classifieds rule 5 - adverts must have the username and date in photos. Adverts failing rule 5 will be deleted

Sewdhull

Members-

Posts

591 -

Joined

-

Last visited

-

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Sewdhull

-

If the motor spins too fast the spinning system doesn't slow down before it cycles again. When a battery has current drawn from it the voltage the motor sees drops, the motor speed drops and the spinning system slows down earlier, perhaps before the next cycle. The amount of slow down is dependent on the internal resistance of the battery and the energy lost is dissipated as heat instead of in spinning the gears in the battery. Dissipate enough heat in the battery and as roger says it gets warm and possibly so warm it splodes. So it becomes important to have your gun fire correctly in the first place and not use the battery to handicap it.

-

Yeah, using your battery to tune your gun shouldn't be a thing. You are deliberately stressing the battery but that's up to you. It's not the batteries causing the issue, it's your setup causing the issue. If you are getting multiple shots on semi it's either overspin or worn cut off lever. Overspin seems unlikely.

-

misfeeds are likely to be the lip end of the rubber being too long and partially obstructing the feeding.

-

It's a science lab populated by research scientists with PhDs. They have proper calibrated kit so yes the weighing is likely accurate. I'd suggest getting the bbs round goes hand in hand with the rights weight( ie the right amount of material) I'm pleased those bbs were satisfactory

-

Yeah you'd need a hundred samples for any statistical meaning, he just chose 10 from 500 or 2000. For roundness you'd probably want to rotate them and try to detect any wobble, on a stream of air perhaps, like you do when you're getting Maltesers by floating them over your mouth and blowing the air out... what, just me?

-

The nozzle needs to penetrate the lips a little so they seal around it

-

I don't. Normally the std nozzle is reused, but if the zci hop is a little further away or closer, or the hop rubber a bit longer in the lips then it varies. You can usually see how far the nozzle comes forward through the bb feed hole, but you'll need to be able to push the cylinder forward so its bit of a pain.

-

Well its one of those things... my money is on the nozzle/ hop meeting, since that's a part you've changed and requires the right clearances and operation to not leak ( randomly or consistently)

-

Well I would suggest if they are getting the weight right they are half way there at least. Perhaps I'll see if my lab buddy can look through a scope at a couple. I'm unsure how you would measure sphericity... Do you?

-

So just out of interest I asked a lab friend of mine to measure the weight some of the BBs I have, all Vorsk ones. Here's his summary. Weight .43g .4g .32g Mean 0.424 0.404 0.324 SD 0.002 0.004 0.001 RSD 0.5% 0.9% 0.5% Median 0.424 0.403 0.324 The BBs were measured, 10 of each from a bottle, to 4 decimal places. Mean is the commonly called average, SD the standard deviation, RSD is the relative standard deviation around the mean, and median is the middle value of the dataset. The .32s had a max and min difference over the 10 samples of .005g, which is just 1.6%. Pretty good I reckon.

-

I am going to regret asking but... Vorsk parts VM9 pistol

Sewdhull replied to Egon_247's topic in General Help

Just say no to spare parts. -

for the thicknesses we can play with, its foams and butyl. Most systems need 25mm or more as the wavelength of the sound reduces ( frequency rises) https://iopscience.iop.org/article/10.1088/1742-6596/1719/1/012062/pdf#:~:text=Commercially available acoustic foam made,coefficient is higher than 0.6. That's for polyurethane foam, I'm sure you cold find others. The goal should be the least noise forward out of the silencer, so we should use diffraction and mass to achieve that.

-

The can has a similar restriction on the front meaning the air will speed up again through the exit hole, I agree this is airsoft and the pressure is pretty low so the pop from the air isn't much and ultimately is probably better managed by voluming. A firearms silencer is all about the combustion gasses and giving them a place to go depressurise and importantly cool down, decreasing in volume. Silencers cool to reduce the pressure... In airsoft all we are doing in allowing the pressure to release slowly, however the gas doesn't cool and contract so playing with volume and baffles doesn't have the same effect. More importantly, absorbing etc, the sound from the piston hitting the cylinder head is the goal, remove the resonance from the can and force the sound through holes which diffract the sound away from the path out the end of the silencer towards the sound absorbent stuff, what ever you use. Simple physics. There's not a lot of room in a can to fit the sort of foam which is effective on walls etc, and foam in speakers isn't about silencing like we are looking at, it is removing resonance from the cabinets so they sound better. The holes are for diffraction and the spaces between the holes filled with something absorbent, there are many to choose from but space is limited so a denser foam, even closed cell types should be tried, but soft may work better, I don't have a range of foams to try. Rockwool is good, but may not have enough volume. 2mm butyl sheet inside the receiver is an idea I wanted to try, but never got round to it.

-

I am going to regret asking but... Vorsk parts VM9 pistol

Sewdhull replied to Egon_247's topic in General Help

Hamster spare parts... its wrong. -

You can't diffuse the air in an open container, it just comes out the other end. I don't see how it's related to the volume of air. The cylinder air will just push the air ahead of it out. You can mitigate the pressure with squidgy things with a view to slowing the build up of pressure in the can like a spring absorbing energy. Air on its own will absorb this energy. The pressure wave or sound wave is different and that's what we are looking to get rid of. The air isn't moving in that case, but a wave moving through the air, which you can deflect, absorb or reflect. Holes deflect the sound direction or surfaces will. Foams absorb the sound wave or filter it so what you hear is less noticeable. The air pressure ahead of the BB is way lower than that behind it, when the BB exits the barrel it is unplugged and then the air pops out which whatever pressure is remaining immediately so I guess you want a larger void, a foamy one behind the BB. A larger cross section of the silencer will slow the expansion more and the idea would be to have a gradual reduction in pressure so there is no pop, you don't need to absorb the pressure. The amount of air (the mass and pressure) will be that same so the hole out of the silencer can't be too small or you'll get a similar pop when the the air compresses again to leave. That's taken care of by the BB needing an exit , around 10 or 11mm on mine. I'm unsure I'm clear, it's late, apologies

-

What is important is where the noise originates and how loud it actually is. The piston hitting the the cylinder head creates a sound travelling right down the barrel along with the excess air popping out the barrel. Well volumed guns may have very little pop, but still have the piston slap noise. You need multiple holes or the sound continues forwards, but honestly the sound levels aren't high to start with so the silencer effects might be lees than expectation and benefit from fewer holes. The holes change the direction not the volume. Interesting huh

-

Yes indeed it is.

-

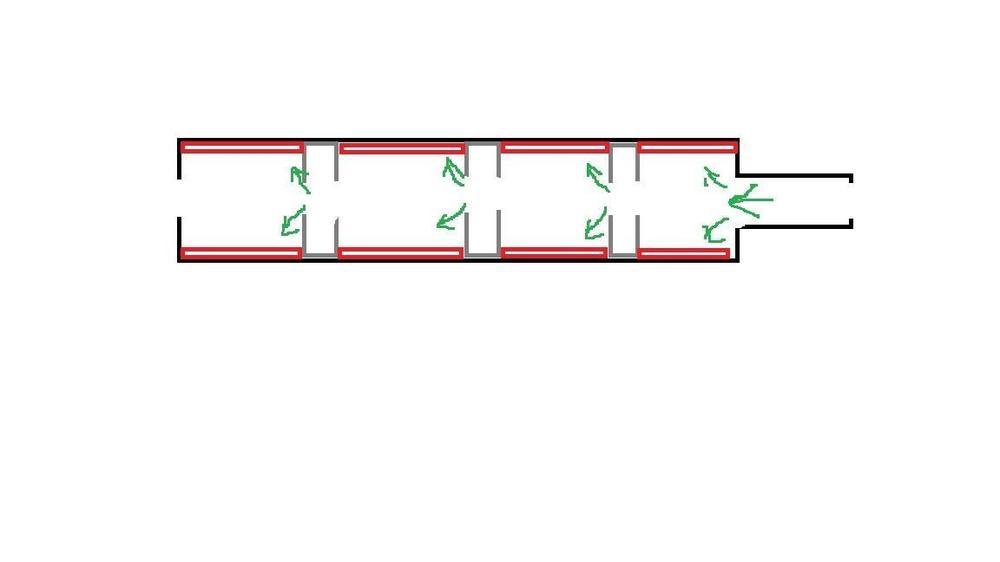

My thoughts and musings. Red is Butyl, grey is hard foam or washer, green is sound. I haven't drawn in the barrel, but there should be a taper ( in butyl maybe) from it to the butyl in the first stage. Send sound through a hole and it propagates outwards in an arc originating at the hole so long as the hole is small enough ( which it is in this case). The sound level reduces with each hole it passes through if steps are taken to absorb the sound after each hole. An empty silencer can rings because of resonance, alter the resonance and can will absorb the sound instead. Absorbent material like butyl is soft and dense, most metals are too hard to use, it will alter the resonance and absorb sound. Foams will only absorb sound. Rubber washers make good separators as does the rubberised foam in HVAC stuff. The volume of air being moved is the volume of the cylinder, you need to reduce the speed of this to reduce the noise and/or absorb that noise. The diameter of the silencer will do this not the volume as the air will slow to fill a wider space but should be gradual to prevent a sudden release of pressure. That amount of air will still be pushed out the end of the silencer so it is always important to not be over volumed or the exit hole of the silencer will behave just like the barrel end but with a larger, quieter exit. The holes in the end of the silencer system will get larger further from the barrel.

-

My Specna RRA SA-E01 is feeding like a PIG now..

Sewdhull replied to Spartan873's topic in Electric Guns

Tube comes in all sorts of wall thicknesses and diameters and tends to be telescopic too. I forget the diameter, but a standard tube size fits inner barrels. I can look when I'm home. You can use a thread lock or epoxy, sometimes it's an interence fit or requires heating/cooling I've just got a hot melt glue gun, I don't know how I managed without one -

Surely in an uncompressed state, but with the preload of installation? Leading to the same thing. Rubber is soft and that alloy looks sharp.

-

We only have some low pressure air and the sound of piston slap to get rid of. The air needs a place to go and the sound needs holes to go through so it bends into the absorbent material of your choice. You do need to deaden the metal tube. I keepeaning to get some butyl in for speriments

-

My Specna RRA SA-E01 is feeding like a PIG now..

Sewdhull replied to Spartan873's topic in Electric Guns

for shimming I use brass or stainless tube slipped over the barrel or fitted in the outer, none of this tape malarky -

Get the rubberised foam used on Hvac stuff, I got mine on amazon, also I have use drubber washers to provide the separation between elements. Or yoga mat material.

-

Can you improve the Tectonic Innovations Quake 8 Impact?

Sewdhull replied to Tiercel's topic in General Help

I've looked at the video and spring tension reduction is probably not going to help, the is only a little resistance it looks like. What would help is increasing the circumference of the round lever, with a rubber ring of suitable diameter. Making the lever heavier will help too.