-

Posts

190 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Wild Weasel

-

Thanks mate, I've been through a fair few like, Geoff's 0.25's, 0.30's, 0.40's and finally ended up on 0.32's for 270fps. I have in the past used bls and tippmann as well. Accuracy wise my best is on here somewhere at around 45x40 @ 20m. 200 pages, woo, hoo!!!!

-

I'm currently reverting back to stock for testing, I don't have a stock float valve anymore as I've butchered a machine screw through it for a DIY npas (my next test nozzle config). But I'm trying to get this mythical +/- 2fps between shots that people have been on about as mine have been anywhere between 2 to 9 feet per second variation between shots and about 13 to 14 feet per second variation over 10 shots with a good 1 to 2 second pauses between shots. Currently I have reverted all my inner barrel components, new barrel, hop, bucking etc to try and sort my accuracy as it has deteriorated, and it is now to the point were I can hit a 325x325 mm steel @ 40m 9 out of 10 shots (50 to 90mm groups @ 20m) on propane with Geoff's 0.32g bb's and a six g nub on a wind less day. Now I want to further improve that by sorting the consistency to help with the vertical spread. In order to do that I have laid out all different nozzle configurations to try and figure out what works best with what I have and I was hoping you guys could try and point me in the right direction yet again. I'm fairly certain there's a lot more that she's got to give, I'm just trying to figure out the best way to get there. Any advice for what to look for with gas routers as they are original and untouched?

-

Right folks I'm still struggling to get my head round consistency here but with regards to the bolt what is the best setup in your opinion for consistency here i.e. for standard TM bolt barrel, nozzle - I have bought a fair few options including npas, g&p three position piston stop, dp valve, TM valve with grub screw drilled through it (went through a little bit pissed) TM nozzle, guns modify drop in nozzle, ag v1 nozzle, TM piston seal, ag v1 piston seal (swollen), dp enhanced piston seal and a few nozzle springs. I'm planning on using a new TM nozzle, TM springs, TM piston seal and the grub screw through the original valve first. If none of this makes any difference I'm going to replace the gas router seals on my magazines Any thoughts?

-

Couldn't tell you, after reading this thread before I bought the rifle I put an angry gun mpa nozzle in immediately, then a npas from r a tech and had FPS fluctuations ever since. These are my findings with the setup at the bottom the piston is lightly greased with tech T salve and mags V1 & V2 are GG modded - I'm ideally after those 2 - 3 FPS variations that some people on here describe but mostly i'd like a set and forget (within reason ~20° c) on propane and geoff's 0.32g at 270fps so I don't have to mess on at chrono and have 4 ok shots and one that goes over wildly:- https://docs.google.com/spreadsheets/d/1lfmKJtQm-qGtE-EJLlXXixfkon5uT6nDdt7BJOOOb1o/edit?usp=drivesdk P.s. Dave - off for some testing at my range today as John at firesupport managed to hook me up with a complete new inner barrel and hop up set!!!

-

Been using r a tech npas, standard setup with geoff's 0.32g bb's. Update one on order from firesupport as we speak. Sorry for the bone questions, I have just finished reading the entire thread again and to be honest there's a lot of conflicting advice, I remember your post now and the take away that I took from that was this item didn't provide enough power and you ended up sanding down the end of the valve blocker and ruining it? Anyway I've bought one now so I will give it a go go and if I need to slightly adjust I will probably lengthen the spring by stretching it or maybe cutting my new amount down till I get a reasonable FPS. I'm going for about 270 FPS on 0.32g bb's Cheers for answering though I will give it a go.

-

Right folks I've had it with npas. What's the best option for sub 350fps on a standard setup using propane?

-

Right folks, sorry I can't for the life of me figure out how to search within a thread but my question is:- asg blaster's- safe enough to shoot for chrono on an mws?

-

Anybody has one of these this please? http://www.wiitech.com.hk/product-detail.shtml?product_id=539&path=57_145

-

I have gg modded all my mags v1 & v2, I think the main issue with it is vertical consistency (as explained to me by @Davegolf) and that is just for the first few shots. I get around 3 BB loads on one mag so 6 mags and a TM xl470 speed loader buried deep in a haley flatpack to keep it quiet from rattling does me for a half days major contact! the one thing that I did do was cut the Syphon tubes to a consistent height and I'm seeing (after the first shot which is always 10fps more regardless of fill) 3-4 FPS difference although my accuracy is crap at the mo but that is due to my barrel and hop I think ( have complete inner barrel set on order) however I have seen a 25mm group at 20metres which is my best so far on og parts with a six g nub. mine and a few others tech data:- https://docs.google.com/spreadsheets/d/1lfmKJtQm-qGtE-EJLlXXixfkon5uT6nDdt7BJOOOb1o/edit?usp=drivesdk

-

Team, I thought I would run this by you and ask your thoughts on this and if I have done something to cause this failure and if so what, so nobody makes the same mistakes. So I got in touch with Miguel regarding the scoring that happened whilst using my Hao Econoline REBCG bolt carrier. This is a fairly large bit of e mail tennis here but if you own a Hao bolt I think it is worth your while to read as the way I have understood it is if you have aftermarket parts on your replica and you have a problem with your bolt they can't help and I believe one other on here has, so if we can figure out what went wrong we can save a buffer tube here and there!!! So crew, what are your thoughts on this as I cannot think of anyone buying this bolt to put in a vanilla Mws? Here is what I've emailed and the response:- Hi, Hope you are all well, unfortunately me and one other on the mws forum have developed a fault with our bolts damaging the internals of our mws's. Much as it pains me to say this as I really love my Hao bolt it has started to create some significant scoring damage to the inside of my buffer tube and upper receiver to the point where I've had to replace my buffer tube and stop using this bolt. Although the dimensions seem relatively close to the original bolt for some reason the roller has scored the lower part of the back of the upper and the buffer tube for which I have had to replace, please see attached photos. I believe however through a slight modification of a smaller diameter roller wheel would help with this problem rather than a complete redo of the whole bolt. I hope you can help with this as I really like the look and the lightweight action of this bolt. Many thanks. Matt Kills him Dear Mills, Sorry for the inconveniences. Id like to know first some of the various in this build ? What receiver and buffer tube are you using ? Yours sincerely, Miguel hao Show quoted text And also the buffer Hide quoted text Service Hao <[email protected]> 於 2021年4月26日 週一 11:11 寫道: Hi Miguel, OEM TM lower, upper, charging handle and buffer were used but after scoring appeared I black permanent markered the scoring and tried different nozzles (as I thought they may change the angles of the bolt + checked the buffer tube wasn't cross-threaded). I tried a g&p aluminium buffer with a dollar coin and faucet washer in the buffer tube (as I was told it may be caused by over- run) I have recently bought a g&p roller weight but that has arrived too late for this buffer tube each time blacking out the scratch and going again, in the end I just stopped using it and went back to the TM original. I have bought a second hand tube from the afuk TM Mws thread guy Wolf for next to nothing so that's all good, but would like to get this bolt working for winter or for a nozzle spring failure mid game. Cheers Matt Mills Dear Mills, We are still figuring out what might cause this problem as our own testing sample don't have such significant wear off . Also, we noted that per your photo shows the wound on the lower receiver which should caused by the over run bcg hitting the receiver. This shouldn't happened if it's the oem marui buffer tube or product of ours . BR, Miguel Show quoted text Yep, Hence the dollar coin and faucet washer now and the reason I don't run a magpull b a d lever with a standard bolt catch plate anymore (c&c maritime bolt catch and g&p lightweight bolt catch plate now) as you have to unwind the buffer tube so much to give the plate time to catch the bolt you end up increasing travel allowing the gas key securing screws on the top of the bolt carrier to catch the top of the lower receiver and crack it. This is prior damage to my Hao bolt days and does not affect it. If you look at the pictures you will see the buffer tube is wound right in with 2 threads remaining so this is no longer an issue. Hope this helps. Cheers Matt Show quoted text Since you have mentioned . We also have the bolt stop plate for this situation as when we developed the 416C mws kit. We were facing a really short travel for the bcg so we made the plate to catch the bolt with a really short travel space of the collectible collapsable stock fyi . https://www.haoptwart.com/product-page/hao-s-light-weight-bolt-stop-plate-for-marui-mws-z So, the nozzle and the buffer tube are all oem while this happening ? Long story short is that our parts should work under fully oem situation and we are not sure how it works with parts fr other manufacturer. You have listed pretty much combination so I got a little confused . BR, Miguel Show quoted text Miguel, I understand your position and I agree I have made my mistakes on this rifle which is why I have reverted it back to original parts for testing - I think the problem I'm having is the profile of the bolt roller wheel being a bit sharper around the edges? Show quoted text Dear Mills, All in all, we can't promise compatibility with other third party manufacturers' products . Our parts are precisely made and tested under fully OEM/HAO's build. Many manufacturers from China/HongKong may not well tested their product before release and the tolerance issue might also be a thing for them. We only have this issue heard from you (and the one you mentioned in the first email ) for now. Other than that, everything is fine for the hundreds of it we sold. We also ran some testing yesterday, nothing noticeable. So we don't think there's problem with the bolt for now. If you still have this issue even under a fully OEM build we are happy to exchange you for the bolt.

-

I bought the c&c tac maritime catch and is fine + half the price!

-

Don't suppose anyone has a 'spare' TM original buffer tube and un-chewed castle nut that they would be willing to sell please as mine has been badly scored by my hao bolt. Cheers

-

I've just ordered a 65° one of these are they the same?

-

Fantastic answer, thanks - I've got some work to do. The reason I went for the G&p buffer is the top screws of the BCG were smashing into the buffer threads on the lower receiver so I was advised to pack it out with a dollar coin and a 23mm tap washer to prevent over-travel and the buffer to prevent bolt bounce. With regards to the hao bolt I'm shelving it as an emergency spare as I did not get these problems with the TM BCG. I think I will give the roller bolt weight a go as it hopefully will smooth out the cyclic action. Once again I'll let you know how I get on. Cheers for the answers everyone.

-

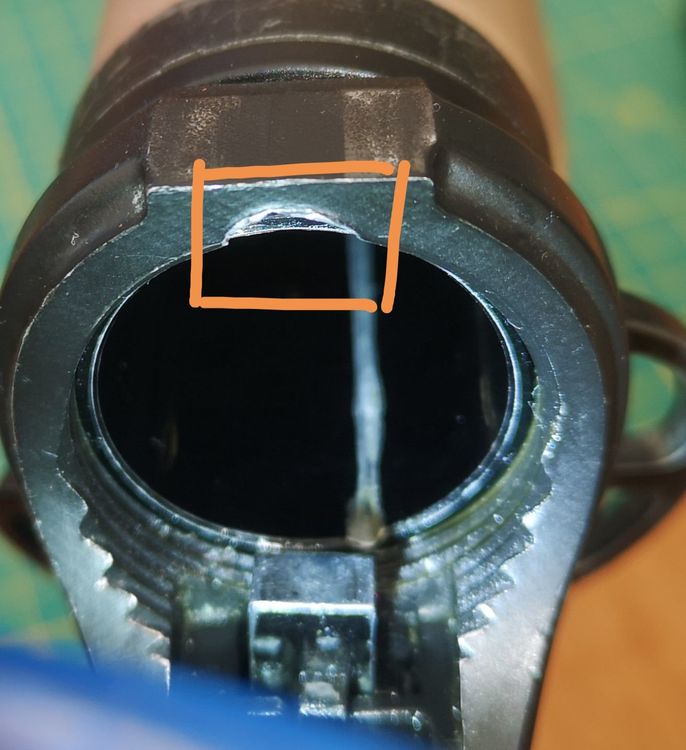

Just checked with calipers and it is within .5 mm so I may have to go to a new buffer tube.

-

It does, thank you but I've pre empted you a bit here - roller weight pt. no. Mws002 on order from Airsoft tiger, angry gun nozzle despite being rather nice polymer and having the guts replaced with npas etc - removed and replaced with a TM original nozzle, dp enhanced sealing buffer. Fitting a new npas on the way from emperion and to top it all off a new 60° Autobot hop rubber. I just want to say, she didn't jack on me and fail, she was just struggling. I'll look into filing the lip on the buffer tube but due to the scoring involved I think I'll just replace. What can you tell me about the roller buffer as it looks a damn good idea. Does it take the pressure off of that wheel at the bottom of the bolt? Cheers

-

Now them team mws, I'm struggling a little bit with my cold weather operation, I know this has been covered before and I'm currently at page 57 rereading the entire thread, in the meantime can anybody give me some tips to get better cold-weather performance out of my mws? My current setup is the following. Hao Econoline geissele bolt Ag MPA nozzle with Ra tech BLK npas ML Mr hop 60° with six g nub TM oem 250mm barrel C&c maritime bolt catch G&g V2 buffer (empty) with dollar coin and 23mm tap washer to shorten stroke (to prevent lower receiver strike from over-travel) Hao 9.3" urgi handguard with BCM foregrip Magpul CTR stock Bcm gunfighter mod 3 pistol grip. Vortex crossfire RDS. Shooting Geoff's .3's bio bb's with rothenberger mapp+ gas. Last shoot she was severely underpowered, barely able to cycle with an FPS of around 200fps on .2's - I've subsequently noticed that the buffer sealing ring made by angry gun was dragging a lot on the inside of the bolt carrier group as it had swelled and become baggy I don't know if this was the cause what are your thoughts? Cheers. Second question of the day, I appear to have developed some scoring on the inside of my buffer tube since using the hao Econoline bolt carrier. I'm thinking of replacing the buffer tube with the the G&P roller buffer tube set will this prevent the scoring and what are the improvements of the roller buffer tube please? Cheers

-

Yeah I've managed to secure a fantastic piece of private woodland for a bit of team training. Unfortunately probably due to my own error my mws is having issues at the moment. My current config is the following. Hao Econoline geissele bolt Ag MPA nozzle with Ra tech BLK npas Ml Mr hop 60° CW six g nub TM oem barrel C&c maritime bolt catch G&g V2 buffer (empty) with dollar coin and 23mm tap washer to shorten stroke Hao 9.3" urgi handguard with BCM foregrip Magpul CTR stock Bcm gunfighter mod 3 pistol grip. Vortex crossfire RDS. Shooting Geoff's .3's bio bb's with rothenberger mapp+ gas. First group I did was 25mm @ 20m then it deteriorated from there ending up at 150mm groups. to resolve this chew I'm having I've pur-chased a new npas (old one was shifting all over and causing my inconsistencies) and a new Autobot 60° (old one got changed as I had bb's dribbling it the barrel, but I think this was the npas's fault not the bucking. and I'll try again from there and let you know how I get on.

-

Nice one, stripped out down and put the silver hop rubber nozzle ring on, noticed even with it fitted it didn't grab the nozzle like the Autobot did though. Cheers Davegolf will be testing super 6g nub with maple leaf 60° Mr hop today at the range so I'll let you know how I get on.

-

Quick question, does anybody use the silver sealing rings on maple leaf buckings as I'm sure I couldn't get the hot chamber closed last time I tried it?

-

So I've had a bit of trouble with my r a tech npas as it just seems to be doing it's own thing and not regulating my fps. I started a shoot at 380 FPS with about 3/4 of a mm wound open and by the end it was around closed hitting 380fps on propane. I did try a bit of thread lock on it but thought it too weak so I found a small o ring (the type found on fill valves) took it apart and put that on to hold it open a bit as I believe you can buy disks to do the same job. Has anyone tried similar? Has anybody bought these disks? If so any chance of a link? Next question, has anyone paired a 60° maple leaf Mr hop with a six g nub yet? I'm getting 15mm groups at 6m but was too windy to shoot down the garden @ 20m.

-

Now then folks, I'm in the market for an ambi fire selector and atrg says that the angry gun one which is predominantly the most available is shite, does anybody have a link to a reasonably priced selector that they have/have tried please?