-

Posts

5 -

Joined

-

Last visited

-

Feedback

0%

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Babo7H's Achievements

-

Thank you @Lozart The Part I am looking for is actually want those letters, this is what my designer has done so far, I think s/he has done a good job. but I wish I could get a real one but thanks again, for the vector file

-

Hi, I have bought a blank receiver from ESD (Skeleton kit called ESD ER-15) and also have bought original BCM exterior parts (hand guard, pistol grip, vertical grip, charging handle, end palte etc) Only naturally I am trying to put BCM engraving on the receiver. I have hired someone to make 3D drawings for the laser engraving(basically I googled the picture of the real thing and gave it to the designer and s/he had done pretty good job), but this isn't exactly the same. I have inquired BCM if I could get my hands on that drawing but I am skeptical about it for an obvious reason. Is there anyone who actually has this drawing in files, or anyone who knows about the font BCM is using on their logo and markings? Thanks !

-

@EDcase 3D Printing is an option, I want it CNCed tho..

-

@Terry_Rist Thank you so much for detailed explanation, I've heard about it will be needing 5-axis machine and all the stuff that I don't fully understand, I just come to wonder, they made this around $50 a piece on a retail price, which means it would have cost less to produce, How many of these do you think they have produced or promised to produced to the machine shop to acheive that kind of low cost if I can make this price happen I maybe able to pull 300 pieces. I think these steel aftermarket parts tends to be less elastic to the price, because airsoft isn't something we need but we want, and people like high-ends stuff like I do... I am willing to pay as high as $200 even $300 why not, but to make this project to live on, maybe something under $100 or $80. I am all over the places here but to summarize 1. How many do you think cowcow had to produce to keep the price that low 2. Reverse designing that part is relatively easy considering the size and simple geometry, but not with 3D scanning but with manual measurement? Thanks again @EDcase I was surprised when Mapleleaf just sent me downloadable file on FB messenger lol, I was being hopeful. I mean it is company asset of course but there isn't a big mystery to it, so I was like why not

-

Rogerborg reacted to a post in a topic:

To produce aftermarket parts

Rogerborg reacted to a post in a topic:

To produce aftermarket parts

-

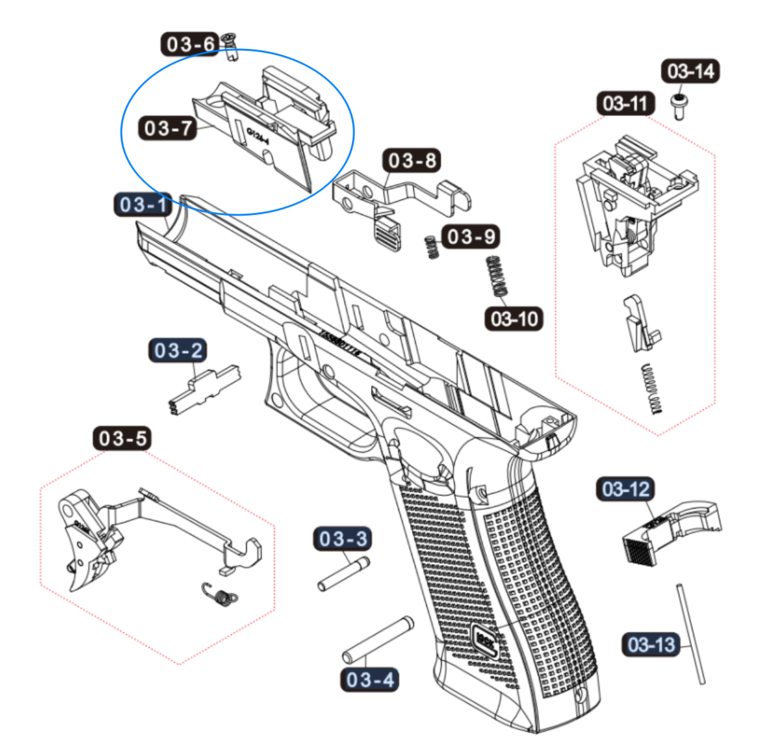

Hi I bought VFC G45(Umarex, Eliteforce whichever it is called) and gathered most of aftermarket parts available in the market. I have notied that no company has manufactured a "Barrel Base" (Parts # 03-7) this piece tends to break on the heavy use yet, there is no aftermarket parts. I would like to make one for myself and possibly for few other people in the community (where i am from) I had no idea how these things work, but I have learrned that we need 3D modeling to begin with, to do so, we need to 3D scan the actual part or reverse design the part, in which way it would cost fortune and time. So I have asked VFC to provide me with the one which they have declined - understandably, but I have asked different company once and they just gave it to me no question asked, which was a surprise. Anyway I was wondering all these aftermarket parts manufacturers for example Cowcow, they have made many parts in steel, does anyone know if they would have been provided with 3D Modeling from VFC with certain contract? or those aftermarket manufacturer also gone thru all those reverse designing and 3d scanning thingy? or do you think anyone or any organization would have that 3D modeling I am looking for? By the way, the part I am trying to build is this part. (the one in the blue circle) Any idea or suggestion for me to accomplish this project would be highly appreciated.