ttony1314

-

Posts

43 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Posts posted by ttony1314

-

-

Not sure if this will help anyone as it is a old thread.

this “issue” is not unique to umarex/VFC GLOCKS, in fact it can happens on any GBB that has a similar rocket valve system.

what happens is when a bb is in the chamber, the back pressure from the BB is pushing back the rocket valve too much that it won’t cycle the slide enough the load the next round, and when the hop is empty, there is no back pressure, it will cycle properly and load the next round. That’s why it only fires every other round.

so the solution is to release more gas to create enough pressure to cycle the slide and overcome the back pressure.

1. Stronger gas

2. stronger hammer spring

3. trim the rocket valve spring coil by coil.

4. My personal favorite, unscrew the release valve on your mag to just before it starts leaking.

and on umarex Glocks, what you can do is just use WE mag( but with TM or VFC gas router).

or use WE release valve on the original mag.

hope this helps someone. -

Not sure if this helps, but looking back at paypal, I have sold one with full RA tech trigger box, Npas 2 spare nozzles, 6 mags + 1 hpa drum mag for 360 3 years ago

The problem now is tho, with all the other brand like GHK and TM all have much better perfroming GBBRs, WE GBBR really took the hit on used market.

I would say start with 150 to 200, and you only have GHK and WE to choice from for a PDW and I havent seen a GHK for a few years now. -

Quick update on trigger group

After about 10k rounds from new I started to see metal shelving in the trigger box when cleaning, so apart from the full auto sear that I can see is wearing there is something else is not quite right.

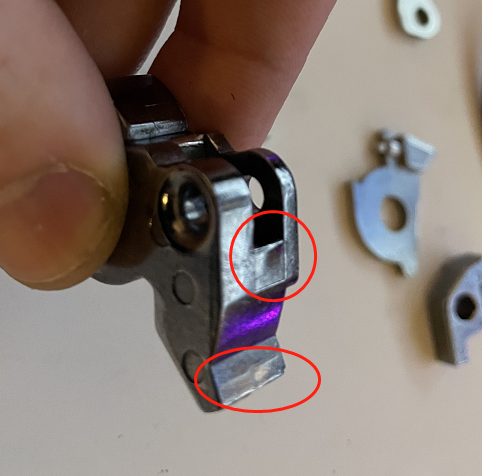

Took everthing apart and found apart from the Hammer, I dont see and wear that worries me. Here are a few pics of the hammer:

As TM only uses soft ish metal on the Hammer with a steel roller, over time the roller keep hitting the hammer and created a "bump" but his does not affect the function as far as I know, but I did seen a post else where this will crack the hammer if not addressed.

other than that, it is just normal wear from the sear realing the hammer.

Here are I think where the metal shelvings are coming from, a part of the hammer keep touching a part of the trigger box casing and cause the coating coming off, and note also the hammer is a bit deformed (the right circle)as that part is also keep hitting the hammer casing.

Here is the the DP full steel trigger set for the MWS installed for now, If anyone wants a to know anymore I will do a write up later on, but in short

1. it is not a drop in fit, if anyone remembers the RA tech Steel trigger set for WE GBBRS, they are not smooth and needs a lot of sanding and polishing to make them run smooth.

2. It is designed in a way to avoid most of the issue above.3. After about 3k rounds I dont see any wear on the full auto sear, not even the gold coating is coming off, it has a must "softer click" to it and that might be why, as the bolt is not hitting it as hard.

4. The trigger dont feel and different on break and reset (still bad) -

Don't have time to read though all 171 pages but here are some findings on gas and please let me know if you have experience the same thing or different.

I have orginally ran my MWS on ASG ultrair, started to have issue with not finishing a whole mag when it is sub 5 degree. Read here that they are not pure Propane hence why the poor performance when Temp is Low.

Switched to Nuprol 2.0, but ran just as bad as the Ultrair, interesting as I thought they are just pure Propane with silicone oil mixed in.

Switch to propane which made the gun run much better even sub 0 degree.

Can anyone comfirm Nuprol is just propane? if yes why there is such a big difference on performance?

FNX-45 - TM or VFC

in Gas Guns

Posted

TM if you dont mind a plastic slide, will always works better and TM has a newer design compare the VFC (they are completely different system).

But have to say VFC is one of the best pistol they made, steel trigger group (the valve knocker/firing pin can still fail)

large rife type nozzle, which makes it works reasonable well in the cold and really well in the warmer months.

But mags are expensive and harder to come by.