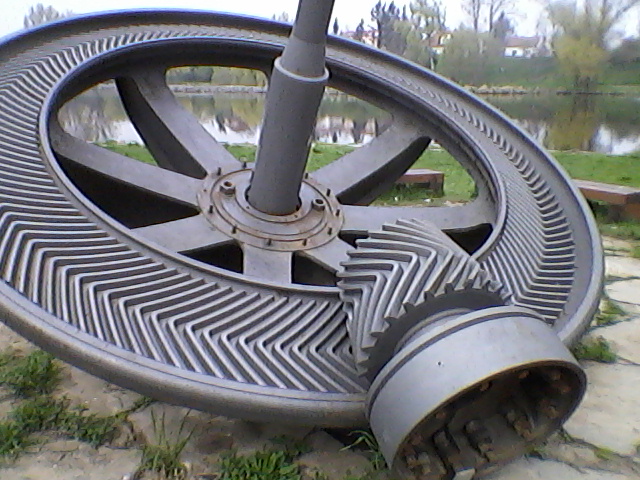

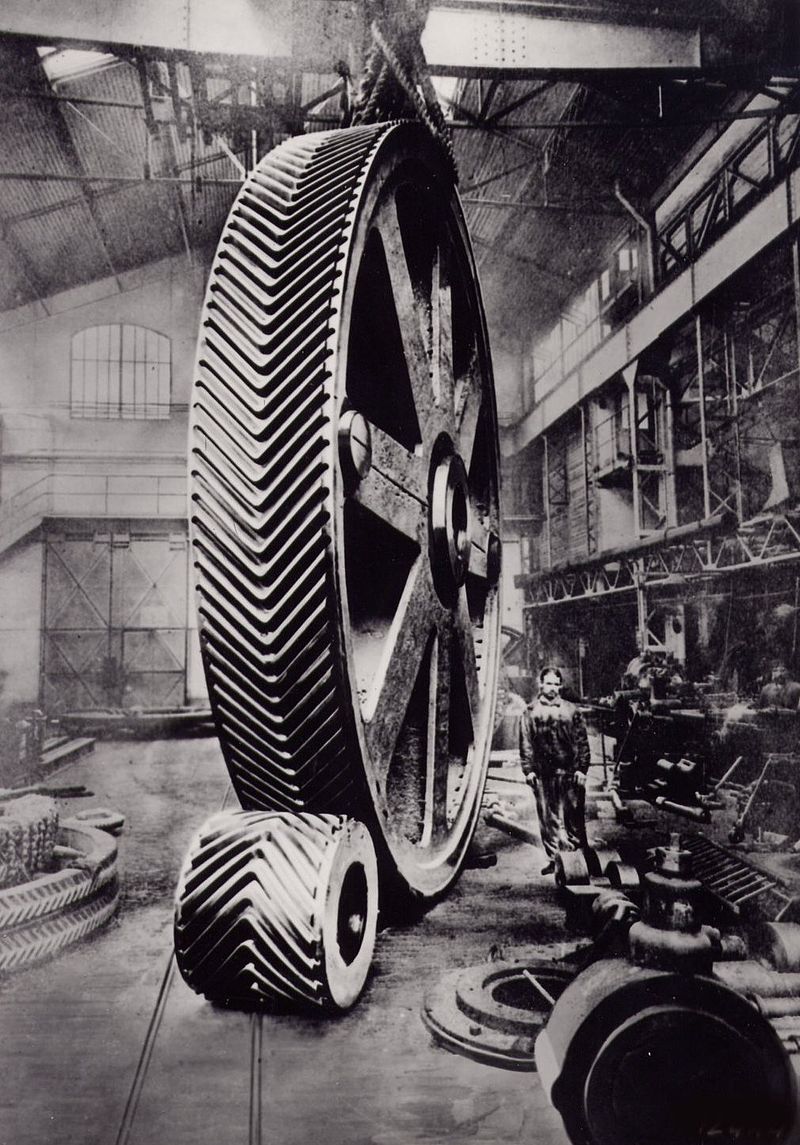

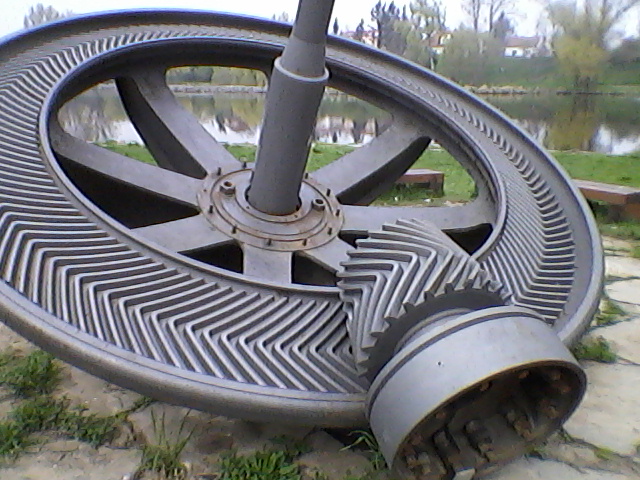

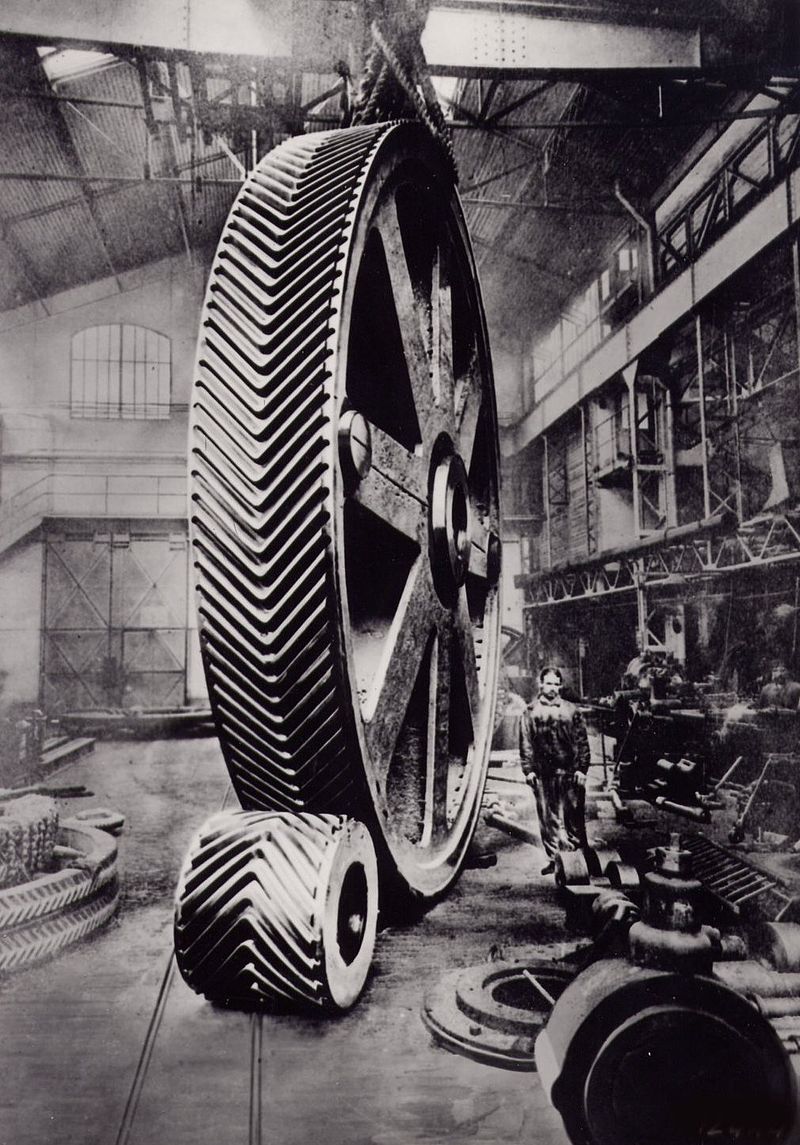

Self centring double helical gears. Would never need shimming and would run with much lower friction that standard or single cut helical gears. Perfectly possible with current powdered metal injection moulding.

Think this.

&

Afaik there is a version of the brushless system with a dedicated channel for rotation, certainly something viable to replace the optical versions in things like the titan.

Cost i cant see as being the big barrier given how much folk will drop on their pews.

Maybe theres a technical reason it hasnt caught on, but then we're dealing with a hobby where nimh is still current tech despite being old hat for over a decade in the rest of the world.

Also liking the look of those gears, its not something i've ever put any study into but i'm reaching the point where gear whine is my number 1 hate.

the issue with the present helical gear sets:

100:200 or 100:300 = a helical bevel gear that afaik they don't sell on their own

meaning if it strips, you can't use any old spare bevel in your junk box

coz there is not regular cut usual 10 tooth bevel gear, but a bespoke helical bevel gear driving the spur etc...

Some of the ideas are taking the basic stuff to the next level

which tbh are we really ready for ???

helical gear set - why not helical pinion

and for that matter why not helical steel rack piston ???

brushless motor - you are still looking at a motor costing 3 times the price of a std neodym motor

(maybe 4 times the price)

and you would need some sort of controller or system board...

placed on/near the motor - it will be getting rather warm/hot

so somewhere inside box perhaps to control brushless/stepper motor

in RC's you need the controller for them motors...

but it "could" be done as we have said

However that is if people really wanted or felt the need to make that next jump in technology

I mean MAYBE some higher end manufacturer could look to implement some fo this

but would they really get a return on it knowing that if successful this innovative design

will just knocked out on the cheap & slapped into cheap mid range China guns within 6~12 months

Personally I think we have around another 2 years, or maybe 3 of squeezing out the max efficiency

in out of the box guns - there is no denying that guns today are offering you much more bang for ya buck

and are setting a revised standard in what we expect at say £100, £150, £200 etc...

Somewhere at say £125 you are expecting - well maybe seeing a gun with mosfet

£150 QC spring gearbox, £175 higher barrel/hop unit & £200 pretty much all if that with a decent or better motor

meaning less must have tweaks required

Bit like TV's - they haven't got insanely cheap that they fall out of cereal packets

but instead you are getting a STFU 50" Smart arse 4k TV for the price you paid for your old crappy 32" box tube telly

(figure of speech, don't quote me on black friday AO deals, nor will a 50" fit in a box of Coco Pops)

Personally I'd like to see some parts made with a bit more allowance for tuning/tweaking

Cylinder heads set back just say 1mm further casting, with sorbo/neoprene or AoE increased a smidge already

V2 gearboxes with trigger "tang" stops/limiters as std - rather just a few reinforced boxes having them

(so you can set the trigger pull limit more easily)

Maybe a V2 with a motor cage - but never caught on...

weird eh ???