Right I have for you an image!

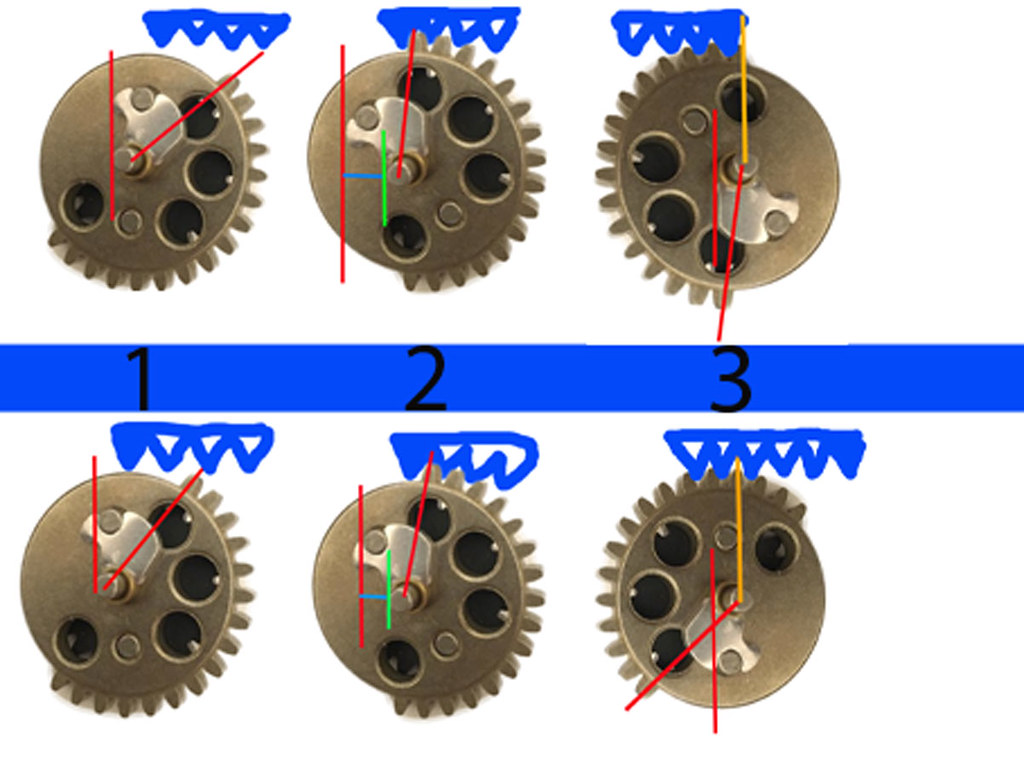

There we have 3 stages of Chip and sector engagement.

Stage 1 on the upper shows the 0 position for the chip (no engagement on tappet plate). You can see the sector gear is not on the piston teeth.. So it is going to keep spinning to stage 2.

Stage 2 on the upper shows the point at which the sector gear has engaged the piston. There is now load on the sector gear that should slow and stop the gearbox. You can see the chip has pulled the tappet plate almost fully back.

Stage 3 on the upper shows the point at which the chip has reset the tappet plate to a 0 position ready to fire. You can see this is right at the very end of the sector gear teeth. So you have maximum delay, and perhaps a problem if you want to reduce teeth on the sector or piston.

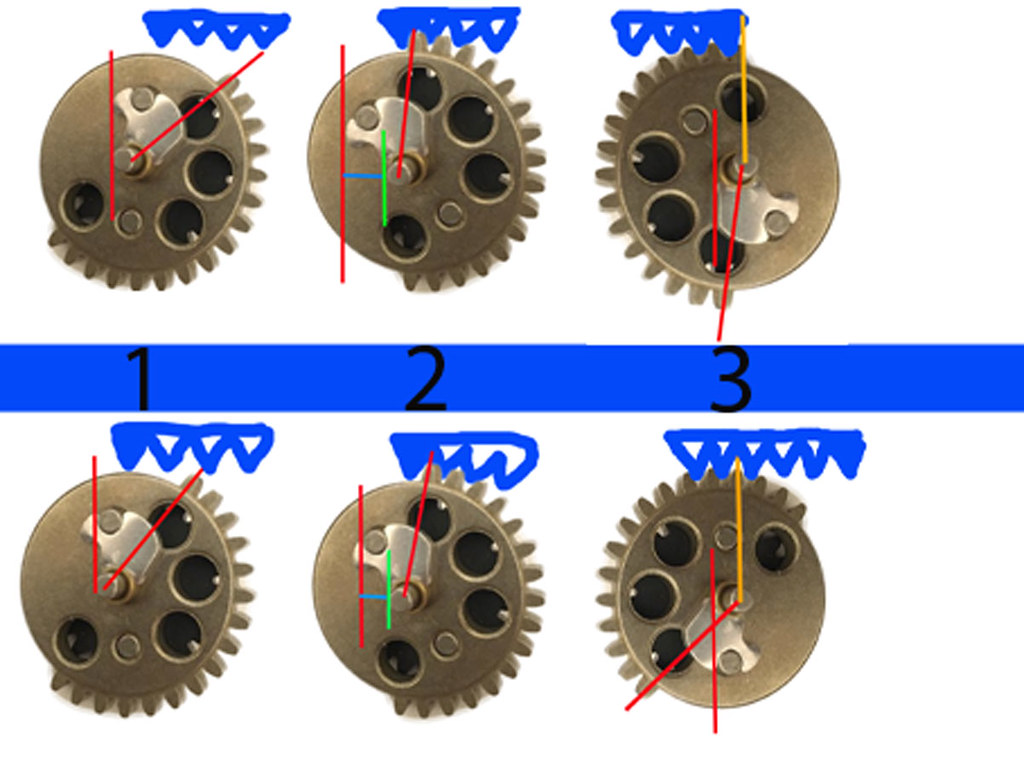

Lower (standard).

Stage 1 0 engagement on the tappet plate happens much later, and the sector is much closer to the piston teeth.

Stage 2 Engagement between the piston and the sector gear. The tappet plate is only just starting to move at this point, And still has several degrees more to turn before full retraction is achieved.

Stage 3 the tappet plate is fully released. Note there are still several teeth left on the piston before it is released.

Stage 2 in all instances will have some roll back and settle action on semi. Depending on the number of teeth on the bevel gear and ARL this distance may be larger or smaller. In a stock gearbox with standard gears the rollback is normally sufficient to allow the gearbox to return to stage 1 (no load on piston sector or tappet plate). A bevel gear with more ARL notches will not allow as much distance to fall back, The gears will be arrested sooner, leaving some load on the tappet plate or piston/sector.

Do you see now why I called the chip huge. It's got a very long holdback time that could cause problems if you short stroke the piston. Regular delay chips are much shorter on the release stage.