Cyberlawyer

Members

- Jan 1, 2020

- 340

- 79

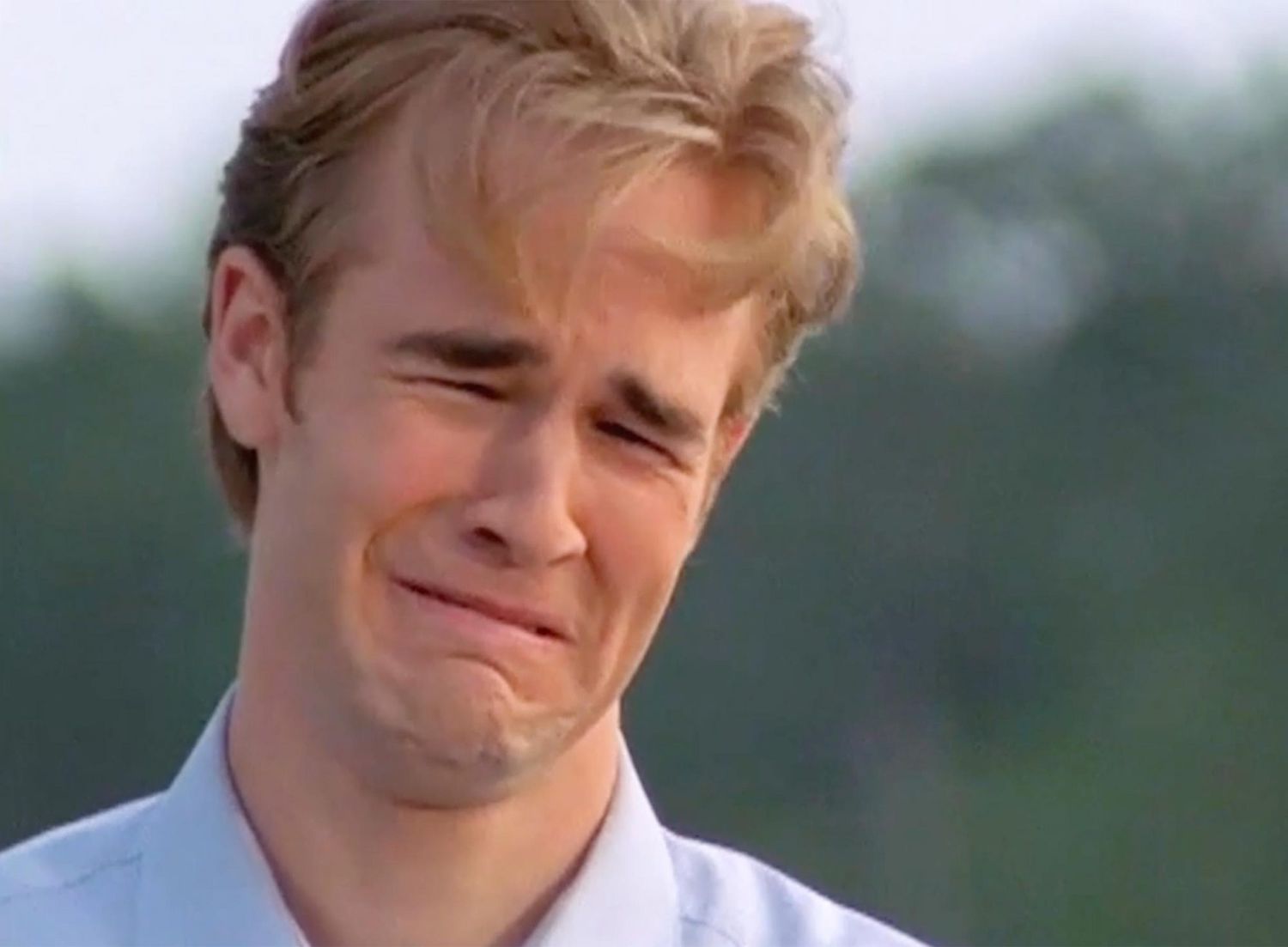

What did you do???

Mine is currently in the back of a UPS truck so I’d be interested to know for when it arrives later today.

Mine is currently in the back of a UPS truck so I’d be interested to know for when it arrives later today.

Last edited by a moderator: