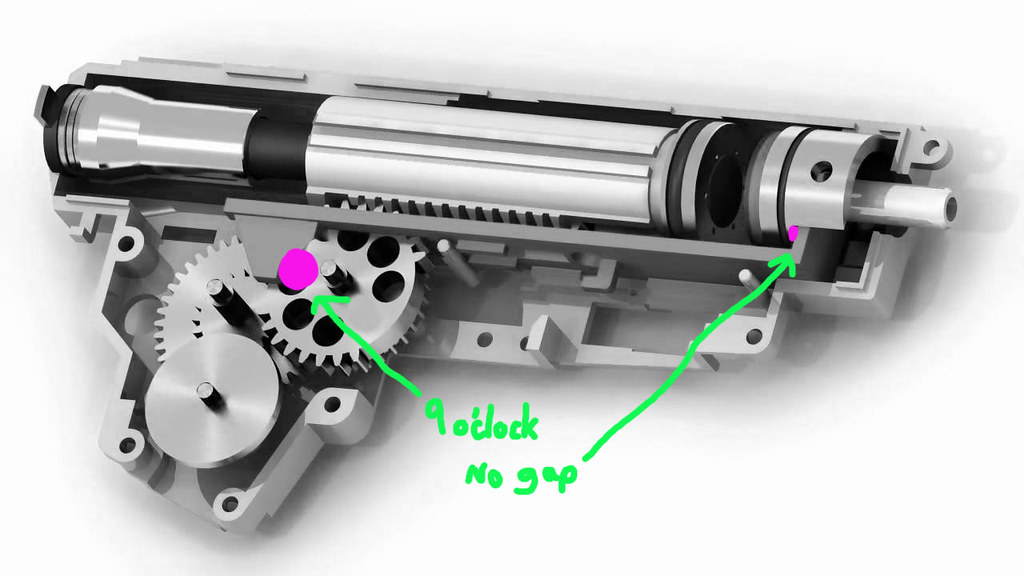

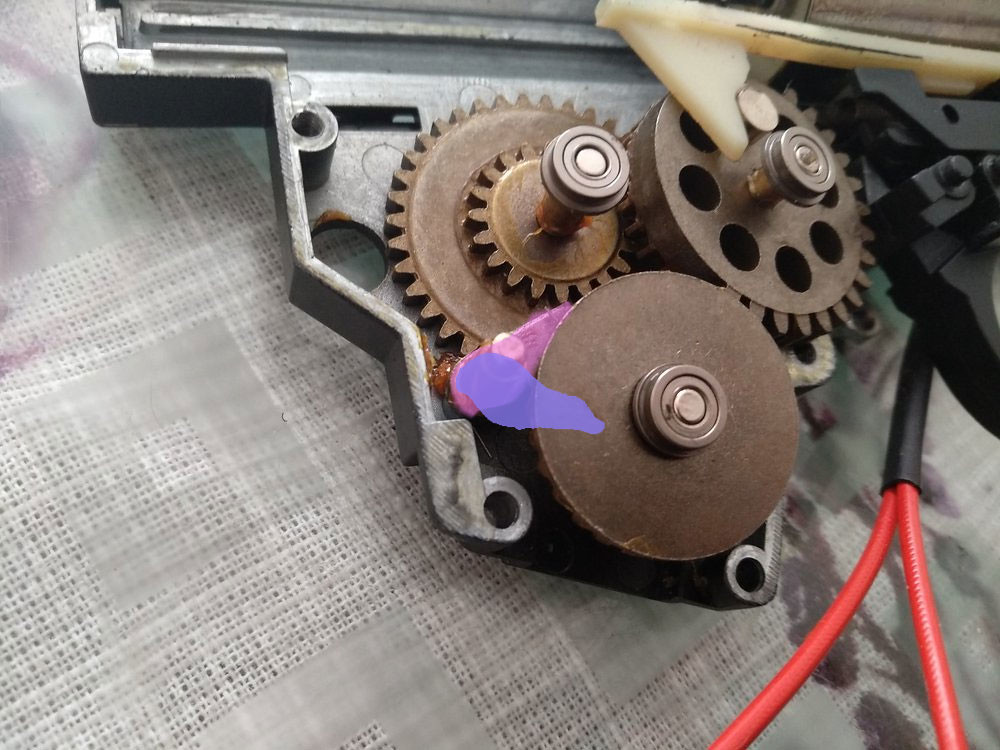

The anti reversal latch is the bit I've highlighted in pink.

It should follow the direction in blue, and catch the other side of the bevel gear. The bevel gear has a pattern cut in it so the anti reversal latch will only allow the gearbox to rotate in one direction.You also have it in upside down I think, the flat side should be on the face of the bevel gear, The curved part should be down under that gear. They require 3 hands to fit.

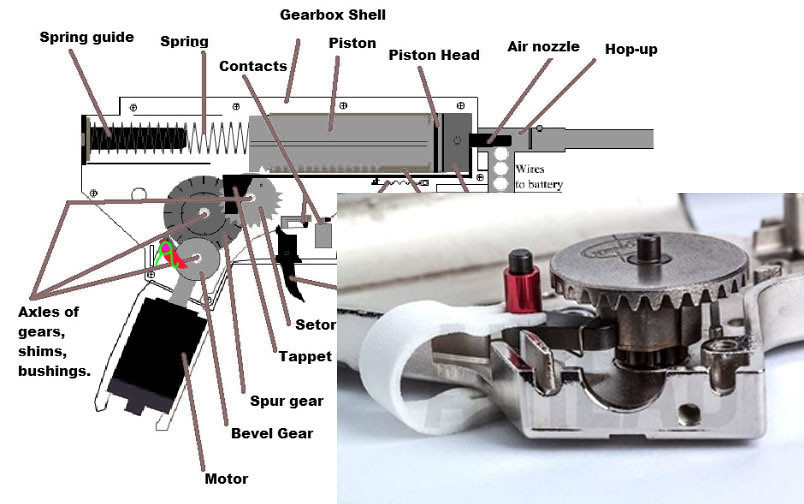

For grease you can use pretty much anything that lubricates and doesn't fly all over the place. There are numerous cheap options but I tend to stick with some cheap Ebay greases that come in handy little pots.

I use this stuff on pistons/air nozzles.

https://www.ebay.co.uk/itm/SYNTHETIC-SILICONE-GREASE-TEFLON-50g-TIN-2HT-PLASTIC-SAFE-LOW-FRICTION-/391399159157?hash=item5b21353575

and this stuff on gears.

https://www.ebay.co.uk/itm/Molly-MOS1-Grease-Airgun-Servicing-50-GRAM-TIN-/173321340281?hash=item285ac1c579

It's nice and cheap, and works really well for airsoft gearboxes. You don't need a lot for it to work just a small dab or two enough to get into the gears and protect them.

It should follow the direction in blue, and catch the other side of the bevel gear. The bevel gear has a pattern cut in it so the anti reversal latch will only allow the gearbox to rotate in one direction.You also have it in upside down I think, the flat side should be on the face of the bevel gear, The curved part should be down under that gear. They require 3 hands to fit.

For grease you can use pretty much anything that lubricates and doesn't fly all over the place. There are numerous cheap options but I tend to stick with some cheap Ebay greases that come in handy little pots.

I use this stuff on pistons/air nozzles.

https://www.ebay.co.uk/itm/SYNTHETIC-SILICONE-GREASE-TEFLON-50g-TIN-2HT-PLASTIC-SAFE-LOW-FRICTION-/391399159157?hash=item5b21353575

and this stuff on gears.

https://www.ebay.co.uk/itm/Molly-MOS1-Grease-Airgun-Servicing-50-GRAM-TIN-/173321340281?hash=item285ac1c579

It's nice and cheap, and works really well for airsoft gearboxes. You don't need a lot for it to work just a small dab or two enough to get into the gears and protect them.

Last edited by a moderator:

.jpg)