hi guys so i'm like half way through my build and the problem is i lost a lot of power and i have no idea what it is. i don't have a chronograph so i cant measure it but it used to go through cans easily and now it doesn't. i noticed that my piston is not going all the way back to the starting position. you think that might be the problem? if so how can i fix it? is it the piston head bearing thats too tight? or is it the spring thats too weak? here is a video of it thanks for help

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

loss of power

- Thread starter kubskihqs

- Start date

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

hi guys so i'm like half way through my build and the problem is i lost a lot of power and i have no idea what it is. i don't have a chronograph so i cant measure it but it used to go through cans easily and now it doesn't. i noticed that my piston is not going all the way back to the starting position. you think that might be the problem? if so how can i fix it? is it the piston head bearing thats too tight? or is it the spring thats too weak? here is a video of it thanks for help

First of all give us some more info on "your build......"

First of all they come in hot from China @ 400fps

So where did you get it and was it UK 350fps

Next what battery/motor are you using ????

You have overspin on semi for starters - not much but raises some questions on juice or motor upgrade ??

The stock Cyma motor is a crap slow 28tps (I've cut one open and then hacked the windings it is about 27/28tpa)

So it's bloody slow rof stock unless you change juice/motor

Overspin is happening if a low spring, worn Cut Off Lever, or fast cycling for setup

The overspin is not bad at all but is still there that is unlikely to take place imho normally slow-ish stock gun

List EVERYTHING so far if/what you did/touched

The overspin is likely a fresh higher than the crap 8.4v 1100 mah it comes with

I assume you might be trying a 9.6v or 11.1v perhaps

but I'm not second guessing $hit until I know a bit more info

Loss of fps is down to loads of stuff but usually seals

is the hop unit pressed back against the gearbox correctly

bucking could be torn - depends on age

piston seals - well it was never fantastic and the cylinder head just falls out anyway

so 350-400fps was with quite crap compression seals in box anyway

so unlikely it got 10x worse than what it was - my guess hop not pressed home against box

or something like that but need more input....

Last edited by a moderator:

- Thread starter

- #3

yeah might be the hop because when i put it all together and try to adjust hopup it wont shoot at all and the overspin might be caused because of the motor i put shs high torque in. also new trigger assembly and cables, and a new bearing on the piston head for more air seal. i have new piston, piston head, cylinder head and air nozzle but it just didn't shoot when i dropped it in. the piston was compressed all the way but it wouldn't go back at all so i just replaced it back with stock parts. but now it lost all power even with old hop unit and barrel so i guess it must be piston/piston head/cylinder/cylinderhead/air nozzle related. im just not sure where to start and how to troubleshoot it. when i saw the piston not going all the way back i thought about motor but im sure it used to be ok with the same motor before. im gonna swap motor for stock right now and check if it overspins.

oh yeah and the battery is 9.6 1600mah

still with old motor it wont go through cardboard and doesn't feed/jams all the time. any other idea?

oh yeah and the battery is 9.6 1600mah

still with old motor it wont go through cardboard and doesn't feed/jams all the time. any other idea?

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

yeah might be the hop because when i put it all together and try to adjust hopup it wont shoot at all and the overspin might be caused because of the motor i put shs high torque in. also new trigger assembly and cables, and a new bearing on the piston head for more air seal. i have new piston, piston head, cylinder head and air nozzle but it just didn't shoot when i dropped it in. the piston was compressed all the way but it wouldn't go back at all so i just replaced it back with stock parts. but now it lost all power even with old hop unit and barrel so i guess it must be piston/piston head/cylinder/cylinderhead/air nozzle related. im just not sure where to start and how to troubleshoot it. when i saw the piston not going all the way back i thought about motor but im sure it used to be ok with the same motor before. im gonna swap motor for stock right now and check if it overspins.

oh yeah and the battery is 9.6 1600mah

SHS HT - not insane but knew it wasn't stock rps

Trigger assembly - really ??? the switch on Cyma v2's have a larger eyelet hole

The Cyma trigger switch contacts MUST be bridged by copper strip on selector plate

A new trigger could have a higher sear, this could be causing the trigger trolley/shuttle

to be later in jumping off the trigger's sear so later popping = more overspin

(also worn COL causes this)

So some of the overspin is down to faster motor/rps & maybe trigger sear later popping perhaps

SHS red nozzles don't sit too well on the clear cyma tappet plate at all - really loose

Piston looks stock, think SHS blues might bind a smidge in there

If gun was hot easy way is to get that bloody 9mm alloy spring spacer out of there

that will drop 30-40 fps then correct AoE - will go from original 400 to 350

So many cut up spring or stuff but you don't need to go butz

If you sort out the major leaks, just new o-ring on good stock piston head

the ptfe the loose as f**k cylinder head -best change perhaps

but if you do this then gun is hot once again - Short stroke if you using metal rack

but you got a low fps gun, long 380mm barrel etc.. so can't/don't need to do this SS crap

(just saying you don't need to buy loads, well SHS HT was a good wise move as cyma motor is crap)

If you use SHSred nozzle then you really need a SHS tappet - they fit nicely

but then you need to file/cut as clear tappet has small cut outs up front like a Lonex tappet

pita no end but more just a bit of work & attention to detail plus how far you go

but most of this is cheap as chips stuff with few extra parts after new motor

If you don't reassemble stuff right though then often you make matters a lot worse

I'd check if the hop is pushed back properly, check if a spring is there keep it checked

or nick one out of ballpoint clicky pen....

- Thread starter

- #5

yeah the new trigger assembly is not bridged on the back where it meets selector plate. you think thats the problem here? and when i put new piston head and cylinder head in together with air nozzle and new tappet plate all shs it has a perfect air seal but it's just weak AF. i also tried to put new spring in which is m120 that i cut down a bit but no better results.

should i bridge it myself? the old contacts are f*cked but i still have those copper plates as i save everything i can from the old stuff.

should i bridge it myself? the old contacts are f*cked but i still have those copper plates as i save everything i can from the old stuff.

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

yeah the new trigger assembly is not bridged on the back where it meets selector plate. you think thats the problem here? and when i put new piston head and cylinder head in together with air nozzle and new tappet plate all shs it has a perfect air seal but it's just weak AF. i also tried to put new spring in which is m120 that i cut down a bit but no better results.

should i bridge it myself? the old contacts are f*cked but i still have those copper plates as i save everything i can from the old stuff.

No no no no.....

if you put in a new switch, say SHS one they don't need the prongs bridged by the plate

THERE ARE NO PRONGS - but just saying the cyma one DID and has a large eyelet/mount hole

replacement switches sometimes need to be made bigger a bit to fit

the cyma box is good sturdy box but just a bit qwirky was what I meant

V3 spring guide in a v2 gearbox

tappet plate with cut outs at front

new switch might need a mod but non-prong switch is better all round

so no panic there

But the new switch, trigger, trolley etc.... "might" be a bit different

it might have a bigger/higher latch/sear

When you replace triggers/switch it can be a be a bit shorter so it jumps off trolley at full pull

Or if it is a bit longer on trigger/sear that pushes trolley it can pop later than usual

as it pops later it disengages later so gun doesn't cut power asap on semi - overspin

other things like worn COL or tight trigger contacts can cause late "popping" of trolley

So when you start change stuff about, it is no surprise things can be different

Often if not careful you can make matters worse with some "upgrades"

If you had a SHS tappet you needed to mod it slightly

If you fitted a new switch, then you needed to solder it in

If you can do that - fit a mosfet then the contacts will last longer than the gun

Without getting too involved or going nutz

it might operate with old trolley in new switch contact block

no need to do anything about prongs/copper plate - not in use on shs switch

but the trigger may pop better on old trolley if not too burnt out

You might have a worn COL but tbh sort out some fps issue first

that seems to be main problem....

I would investigate the hop unit myself

if you changed/upgraded stuff there please list

often bad reassembly of hop unit results in bad feeds/seals

sometimes it is advisable to build a complete 2nd hop/barrel

that way if stuff goes wrong you got original stock one to get you going until sorted

some hops can be picky with some guns (pro-win units either work great/crap)

some buckings in some hops can be tight, the lips restrict feeding they are pinched

also fitting wrong nozzle length etc.....

Right is the hop unit still stock or you messed with that too

did you ensure hop pressed back with spring

(mag when inserted can try to push hop away and drop seal)

so you used a SHS red nozzle in a shs tappet and modded it

did you sand the front of tappet to ensure nozzle sits forward

lmk what else you did/didn't do...

Last edited by a moderator:

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

yeah mosfet and 11.1 was my next upgrade but i have to workout why it lost the power now

edited but repost a bit of it....

I would investigate the hop unit myself

if you changed/upgraded stuff there please list

often bad reassembly of hop unit results in bad feeds/seals

sometimes it is advisable to build a complete 2nd hop/barrel

that way if stuff goes wrong you got original stock one to get you going until sorted

some hops can be picky with some guns (pro-win units either work great/crap)

some buckings in some hops can be tight, the lips restrict feeding they are pinched

also fitting wrong nozzle length etc.....

Right is the hop unit still stock or you messed with that too

did you ensure hop pressed back with spring

(mag when inserted can try to push hop away and drop seal)

so you used a SHS red nozzle in a shs tappet and modded it

did you sand the front of tappet to ensure nozzle sits forward

lmk what else you did/didn't do...

when did this power loss come about

before you replaced stuff or after or a bit of both....

- Thread starter

- #9

yeah im sure its not hop because i have two barrels and two hops one stock and the other one is shs prowin style hop on a zci 6.02 barrel. both have no power and miss feed/don't feed at all and jam.

and the power dropped today when i fitted everything together and now i replaced it back with old stuff and see no change i'm troubleshooting everything now so its gonna take some time

i didn't mod the tappet plate im not sure how to do it should the air nozzle be like straight with the rest of the gearbox? its a bit up now

and the power dropped today when i fitted everything together and now i replaced it back with old stuff and see no change i'm troubleshooting everything now so its gonna take some time

i didn't mod the tappet plate im not sure how to do it should the air nozzle be like straight with the rest of the gearbox? its a bit up now

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

yeah im sure its not hop because i have two barrels and two hops one stock and the other one is shs prowin style hop on a zci 6.02 barrel. both have no power and miss feed/don't feed at all and jam.

and the power dropped today when i fitted everything together and now i replaced it back with old stuff and see no change i'm troubleshooting everything now so its gonna take some time

i didn't mod the tappet plate im not sure how to do it should the air nozzle be like straight with the rest of the gearbox? its a bit up now

BOTH BARRELS/HOP Playing up ???

That ain't right at all..

ARGHHHHH friggin' laptop crashing twice in 20 mins

Twice got BASIC dumping memory crap....

THREE TIMES NOW BASIC FFS !!!!!

An SHS TAPPET plate needs a bit of a mod or it won't go in the box

Compare the SHS tappet same width all way along

The clear one has say 1.5 to 2mm filed down at front either side

The SHS tappet needs modding to operate

Im shocked you can close the box up tbh

Compare the blue SHS to clear cyma tappet

SHS tappet can also do with a file or sanding at front to help them sit as far forward as possible

I'm typing this on my crap fone atm

If my laptop reboots and behaves I'll post some pics

As a pic says 1,000 words

Last edited by a moderator:

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

nice one thanks and yeah i never fitted that shs plate because it wouldn't close but now i know why. i was using my old plate all the time

F**k me 4th crash bsod

Think laptop memory/hd is bored or deep virus scan/malware needed

I'll nick another laptop later and update with stuff

But the cyma boxes are a bit qwirky and tweaks/upgrades are never just drop in and off you go as you are finding out

You can't just drop in 13:1 gears - mod req

Tappet plate is a bit odd/qwirky so needs a mod too

Nothing major but it is a decent but qwirky strong but cheapo box

Just need to be aware of some crap n stuff before you year her open etc...

List up EXACTLY what is in there and what is & isn't stock first atm

V2 gearboxes have a smaller "tappet or nozzle window" than v3's

So the tappet plate plate at say 3mm thickness at front retracts about 7 to 7.5mm max. What this means you need at least 6mm for bb plus about 1mm to press on bucking lip to seal. So you got very little leeway to feed/chamber a bb. Add in a bit of wear n tear plus some variation of tolerances and no wonder stuff don't always work 101%.

Even reassembling the box, if you tighten up say the stock tube too tight the box can tilt upwards and misalign a whisker

You say nozzle is tipping up, the nozzle should be straight as a die out if box not tilted up/down

You can fit delayers and other stuff but the tappet could retract too far back and bottom out or bend up on the cylinder head. Promoting quicker wear or damage to tappet plate etc...

It is a bollock ache doing stuff, you need to check EVERYTHING

AND I DO REALLY MEAN EVERYTHING you replace

TM Compatibility is a myth, very often stuff needs a slight tweak

And chucking stuff in rarely works as it should

On the qwirky cyma box, many things need a tweak

(As you are finding out, most stuff rarely works as it should. Though this cyma box is bit more qwirky than most others out there)

Still my fone but I will sort out a shortlist of stuff to check

Yeah, me write a short list that will be a first....

Gimme 12 hours or so and update us with as much info

No matter how small so far

What it will take is YOU thoroughly checking EVERYTHING

YOU doing the work, I can only offer suggestions

It is your box, your eyes, your hands and your attention to detail

Meantime I'm slapping a laptop but I'll update some more stuff very soon

Last edited by a moderator:

- Thread starter

- #13

ok so now im putting in everything i have which is: shs bushings, m120 spring shs black, shs purple piston i think its 15 teeth not sure rn, flat piston head 6 holes with ball bearing shs red, stock cylinder, shs cylinder head with 2 orings shs red, nozzle with oring shs red, stock gears but i have 13;1 gears i have done the mod to the gearbox and they spin freely when gearbox is together but when i put in motor it just locksup the whole gearbox and i have to open it again so i put old 18;1 gears, spring guide with ball bearing and yeah i think thats it im putting it together right now and i try it out

actually f*ck it i'm gonna do it tomorrow just checked the time and its waaaay too late for this stuff so will update you as soon as i do it tomorrow

actually f*ck it i'm gonna do it tomorrow just checked the time and its waaaay too late for this stuff so will update you as soon as i do it tomorrow

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

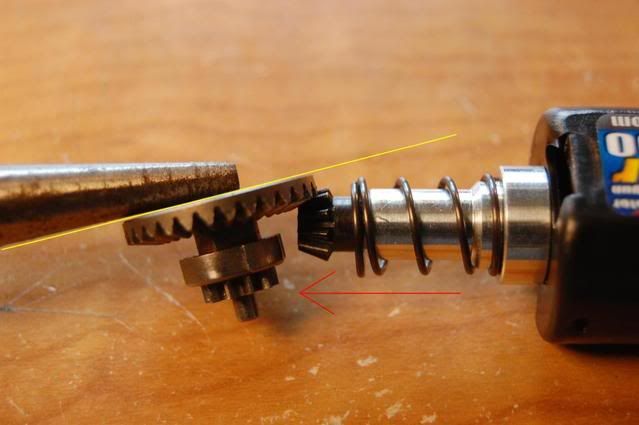

To use a SHS tappet plate it needs modding like the cyma one

ignore the reshaping of tappet fin on left side

focus on the right side SHS tappets before/after

Then the SHS nozzle will sit in the SHS tappet plate

The front of the SHS tappet should be sanded imho

it is about 3mm thick and the lug where the nozzle sits upon is off center

the lug sits a whisker backwards from center - slightly to the rear

so by sanding the tappet plate front the whole things will return a whisker more forward

Basically place the damn SHS tappet plate on a flat surface and sand emery paper

and just go nuts in a circular motion, feel free to file off if you wish but try to keep straight/square

at least finish off on sanding down the front of tappet plate a bit

Not massive amounts, but say from 3mm or just over to about 2.65/2.7mm (every little helps)

Also worth noting SHS tappets are often known for two things....

They retract a smidge further back than most other tappet plates

They often are a bit slightly bent/warped or not truly 101% straight or true right angles up front

If quite bent or not true 90 degree angle at front then use boiling water in a cup to help straighten

(carefully whilst in cup or freshly removed - you won't reshape them any way without heat)

Also as mentioned V2's are less forgiving as v3's in total tappet/nozzle travel or window

Or in other words less tappet travel = less tolerance to chamber & feed then seal on bucking lips

The v2 has about 10mm distance

The v3 has about 11mm distance

take off 3mm tappet thickness and you haven't got loads of leeway for margin of error on v2

Hence worn tappet fins, correct nozzle length is much more critical on most v2's

The SHS nozzle should fit on SHS tappet - providing you modded it to work in cyma

It never truly sits smack bang in bottom of the " U " but about 0.5mm just short of it

You can decide if you add superglue/epoxy to affix it if needed

If so you may need to install the cylinder + head + nozzle + tappet + perhaps tappet spring

you might not need to install the tappet spring, I've glued with/without spring and good/bad results

IF you glue it, shouldn't need to but if you glue it you need to check how it sets

The nozzle MUST BE as truly straight as possible, not pointing up/down loads

Straight nozzles operate & perform a great seal - well nuff common sense said really

Just check it sits & moves straight is the end final result....

SHS tappets retract more, so you really shouldn't need a delay clip as such

Often some types can retract the tappet a whisker further as well as longer duration

SHS ones going back further can often bottom out on cylinder head and bend/bust if not careful

All tappet plate stuff should be checked in top half of box

place cylinder head + cylinder + tappet/nozzle in there then sector gear

rotate sector gear to pull back tappet plate checking for max retraction & return

Hopefully it should not hit the cylinder head/cylinder on full max retraction

Hopefully it should return 101% fully home too, though it might be restricted by sector's axle

If so you may have to file an arc shape in line with sector axle to allow full 101% return

I'm just telling ya how to check crap properly or more thoroughly but it is not written in stone

Just you can sort of check with everything in box like you assemble it

But checking this tappet crap in top half of box is far more accurate or precise imho

Also check other crap on full retraction whilst you are about it...

The back of the fin can hit on re-enforced boxes or on the spurs axle in some cases

So pay close attention to all of this tappet plate movement crap

watching how it moves, full retraction/return and if hits on anything in process

Bet you thought a tappet plate was just a thing you dropped in and that was that

Well yeah, but if you check this stuff first it can/will save you possible headaches

Going back to first pic, I modded the fin filing an arc where sector axle was

because the tappet now sanded at front wanted to shift forward more and I was sure

(by checking in other half), the fin was hitting sector axle, so filed a circular/arc at axle point

The fin was trimmed because I was using a delayer but didn't want it held back too long

(I was mainly using the delayer to retract tappet even further rather than for duration)

If you look at delayer itself it has a slither of material over the original tappet cam lug

So it pulls the tappet back even further but it will hit cylinder head so more mods

(ignore most of this as it is just me being a tart and experimenting with crap)

Just check if you need to make a small mod if sector axle is impeding tappet max full return

Yup the usual Red SHS M4 nozzle doesn't too well in clear cyma tappet plate

The cyma/lonex type tappet plate is a bit of a pita as you gotta mod a regular one

But the black plastic SHS nozzle with slotted design sits better in cyma tappet

not tried it yet in a build but kinda getting fed up messing with stuff at times but seemed better

https://gunfire.pl/product-eng-1152208695-M4-Replica-Nozzle.html

not seen myself other SHS types they do but TZ0100 deffo fits better in cyma tappet plate than Red one

The idea like in small pic, it is supposed to reduce "bb suck" but tbh if piston head functions correctly

Then air should fill cylinder anyway

Also it is supposed to ensure bb is chambered into hop into bucking correctly

There is a possible trade off that the " slot " or extra plastic may restrict air flow from nozzle/turbulence

But I don't f**king know as I haven't tested it all out - just know it sits in cyma tappet plate better

(so don't ask me if it should mount with slot vertically or horizontally - I don't know)

Beware of mounting plastic nozzles into tight tappet plates, they can in rare cases on softer nozzles

distort very slightly and create a slight oval shape if a plastic nozzle is squished into a tight " U " tappet

Not seen this odd hex type nozzle about....

But SHS homepage has moved/expired so can't seem to locate lots of other types of nozzle info

There are two red nozzles - most use the single o-ring type:

https://gunfire.pl/product-eng-1152195485-Dysza-do-M4.html

there is also the double o-ring type:

https://gunfire.pl/product-eng-1152200427-M4-Replica-Nozzle.html

(has a cross type front end of nozzle to reduce bb suck - nah most use the usual one o-ring type)

Just saying there are nozzles & there are nozzles, just to add to the headache

Yup think that covers most of the tappet/nozzle stuff crap atm

ignore the reshaping of tappet fin on left side

focus on the right side SHS tappets before/after

Then the SHS nozzle will sit in the SHS tappet plate

The front of the SHS tappet should be sanded imho

it is about 3mm thick and the lug where the nozzle sits upon is off center

the lug sits a whisker backwards from center - slightly to the rear

so by sanding the tappet plate front the whole things will return a whisker more forward

Basically place the damn SHS tappet plate on a flat surface and sand emery paper

and just go nuts in a circular motion, feel free to file off if you wish but try to keep straight/square

at least finish off on sanding down the front of tappet plate a bit

Not massive amounts, but say from 3mm or just over to about 2.65/2.7mm (every little helps)

Also worth noting SHS tappets are often known for two things....

They retract a smidge further back than most other tappet plates

They often are a bit slightly bent/warped or not truly 101% straight or true right angles up front

If quite bent or not true 90 degree angle at front then use boiling water in a cup to help straighten

(carefully whilst in cup or freshly removed - you won't reshape them any way without heat)

Also as mentioned V2's are less forgiving as v3's in total tappet/nozzle travel or window

Or in other words less tappet travel = less tolerance to chamber & feed then seal on bucking lips

The v2 has about 10mm distance

The v3 has about 11mm distance

take off 3mm tappet thickness and you haven't got loads of leeway for margin of error on v2

Hence worn tappet fins, correct nozzle length is much more critical on most v2's

The SHS nozzle should fit on SHS tappet - providing you modded it to work in cyma

It never truly sits smack bang in bottom of the " U " but about 0.5mm just short of it

You can decide if you add superglue/epoxy to affix it if needed

If so you may need to install the cylinder + head + nozzle + tappet + perhaps tappet spring

you might not need to install the tappet spring, I've glued with/without spring and good/bad results

IF you glue it, shouldn't need to but if you glue it you need to check how it sets

The nozzle MUST BE as truly straight as possible, not pointing up/down loads

Straight nozzles operate & perform a great seal - well nuff common sense said really

Just check it sits & moves straight is the end final result....

SHS tappets retract more, so you really shouldn't need a delay clip as such

Often some types can retract the tappet a whisker further as well as longer duration

SHS ones going back further can often bottom out on cylinder head and bend/bust if not careful

All tappet plate stuff should be checked in top half of box

place cylinder head + cylinder + tappet/nozzle in there then sector gear

rotate sector gear to pull back tappet plate checking for max retraction & return

Hopefully it should not hit the cylinder head/cylinder on full max retraction

Hopefully it should return 101% fully home too, though it might be restricted by sector's axle

If so you may have to file an arc shape in line with sector axle to allow full 101% return

I'm just telling ya how to check crap properly or more thoroughly but it is not written in stone

Just you can sort of check with everything in box like you assemble it

But checking this tappet crap in top half of box is far more accurate or precise imho

Also check other crap on full retraction whilst you are about it...

The back of the fin can hit on re-enforced boxes or on the spurs axle in some cases

So pay close attention to all of this tappet plate movement crap

watching how it moves, full retraction/return and if hits on anything in process

Bet you thought a tappet plate was just a thing you dropped in and that was that

Well yeah, but if you check this stuff first it can/will save you possible headaches

Going back to first pic, I modded the fin filing an arc where sector axle was

because the tappet now sanded at front wanted to shift forward more and I was sure

(by checking in other half), the fin was hitting sector axle, so filed a circular/arc at axle point

The fin was trimmed because I was using a delayer but didn't want it held back too long

(I was mainly using the delayer to retract tappet even further rather than for duration)

If you look at delayer itself it has a slither of material over the original tappet cam lug

So it pulls the tappet back even further but it will hit cylinder head so more mods

(ignore most of this as it is just me being a tart and experimenting with crap)

Just check if you need to make a small mod if sector axle is impeding tappet max full return

Yup the usual Red SHS M4 nozzle doesn't too well in clear cyma tappet plate

The cyma/lonex type tappet plate is a bit of a pita as you gotta mod a regular one

But the black plastic SHS nozzle with slotted design sits better in cyma tappet

not tried it yet in a build but kinda getting fed up messing with stuff at times but seemed better

https://gunfire.pl/product-eng-1152208695-M4-Replica-Nozzle.html

not seen myself other SHS types they do but TZ0100 deffo fits better in cyma tappet plate than Red one

The idea like in small pic, it is supposed to reduce "bb suck" but tbh if piston head functions correctly

Then air should fill cylinder anyway

Also it is supposed to ensure bb is chambered into hop into bucking correctly

There is a possible trade off that the " slot " or extra plastic may restrict air flow from nozzle/turbulence

But I don't f**king know as I haven't tested it all out - just know it sits in cyma tappet plate better

(so don't ask me if it should mount with slot vertically or horizontally - I don't know)

Beware of mounting plastic nozzles into tight tappet plates, they can in rare cases on softer nozzles

distort very slightly and create a slight oval shape if a plastic nozzle is squished into a tight " U " tappet

Not seen this odd hex type nozzle about....

But SHS homepage has moved/expired so can't seem to locate lots of other types of nozzle info

There are two red nozzles - most use the single o-ring type:

https://gunfire.pl/product-eng-1152195485-Dysza-do-M4.html

there is also the double o-ring type:

https://gunfire.pl/product-eng-1152200427-M4-Replica-Nozzle.html

(has a cross type front end of nozzle to reduce bb suck - nah most use the usual one o-ring type)

Just saying there are nozzles & there are nozzles, just to add to the headache

Yup think that covers most of the tappet/nozzle stuff crap atm

Last edited by a moderator:

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

Other stuff......

Are you absolutely sure the SHS piston doesn't bind thus increasing load

Don't know about purple, but sure when I tried a blue it seemed to bind a bit

This is in an APS box but SHS blue metal racks are lovely but bind in many boxes

The piston MUST slide back in a fully enclosed box and MUST FALL when inverted

Often pistons seem to bind at the furthest point back for some reason

(Don't know why but it seems if it will start to bind it will be right at back)

Binding pistons will rob you of rps & fps (sluggish return), increased load/amps/heat etc...

Also some pistons or rather the way their teeth are on the piston can bottom out on full retraction

Right at the final final point of release, the last tooth is set is set slightly different to other pistons

meaning it is trying desperately to pull the last 0.5mm and then slip, but back of piston hit back of box

Not wise to think - I'll file the back of piston, you lose strength on rack/pick tooth

If it seems like it is bottoming out, then file either sector's last tooth or piston rack last tooth

Not a lot, just say 0.5mm to 1mm absolute max, helping it to slip that little bit earlier without bottoming out

Not a problem for me if I Short Stroke a couple teeth on medium barrel setups - never bottom out

MadBull Alien pistons were known to bottom out in some boxes

Piston head, well if you use the bearing inside remember to ensure you use thread lock (blue)

These bearings inside piston often come apart in use - hence thread lock is a must

I & others drop these bearings as they weigh about 4gms or so

Try swiss cheesing 4gms - yeah right, if you can use a nylon spacer @ 1gm that is 3gms saved too

(if you manage to swiss much past 3gms then you are REALLY going some crazy stuff)

I presume you correct AoE - nuff info out there

you lose a bit of fps/stroke but a bearing spring guide helps to replace lost fps (not stroke/volume)

But CM515 should use a full cylinder anyway - bit over volume for 380mm barrel but yeah you are fine

(or a type 1 with slits right at the very back of it, but full cylinder will be ok with a bit extra for 0.25's etc...)

Gears - well cyma stock gears are robust but do run a bit rough, plus the bevel never meshes smoothly

(well imho it always sounds a bit shrilly - the angle meshing with pinion isn't anything like true 90 degrees)

A far fetched example - but if you press the pinion firmly into bevel it "should" be at 90 degrees

Don't know why but the Cyma bevel with its #1 stamped on it often sits at say 85 degrees

So all teeth on both gears never can fully 101% engage

You should also check how well they roll around each other

As well as the motor angle on these two gears before you even bother check height/shimming

Just personally think there are a few basicchecks how some bevels and some pinions all mesh together

think this might be why some gears and some builds sound more shrilly than others no matter what

Some gears are just rougher than others and the cyma gears do run a bit rough imho

BUT - why change the cyma bushings ? They are decent 8mm cross types, filled with grease and all fine

Think SHS bushings are even chunkier tbh, unless you use the black enhanced ones:

https://www.ak2m4.co.uk/internal-parts/bushings-shims/zci-bushings-8mm-enhanced

NB: I'm only guessing they are thinner or protrude less - they look a bit like VFC bushings

Which on a VFC box I had seemed a lower profile or just sat lower than usual

But this could have also been down to the bushing holes or the VFC box itself....

View attachment 33426

But the black VFC bushings deffo didn't sit so proud like regular chunky mofo bushings like SHS

Usually as said....

Bushings protrude further into box, especially SHS ones, had to sand on a table the top bevel one

Quite a while I was sanding round in circles trying to reduce the bevel's SHS bushing just get a 0.10 shim

With Cyma stock bushings & SHS 13:1 you would have likely needed just 0.20mm on top of bevel gear

The spur gear, on SHS you might have run into an issue though

The spur is much more chunkier, even with say 0.1 or 0.15mm shim underneath you may found it tight

I have hadto put a 8mm bearing on top of spur gear to give me a slither more room to shim spur gear

(see first tappet picfor 8mm bearing on spur gear)

The sector gear, you wouldhave roughly spaced it half n half as a guide then checked operating

eg: not rubbing on spur (swirly pattern), or too low that rubs on COL or too high it rubs on case/tappet

(check sector in box when checking tappet operation etc... just in case anything rubs)

This is NOT a shimming guide but more of a rough - VERY ROUGH ball park starting point I found

You need to check motor height properly YOURSELF and determine how the bevel is shimmed !!!!

The trigger/switch/COL stuff well I mentioned that but main issue is getting the fps/seals sorted

This is also not a guide on how to tweak cheapo Cyma M4's either....

It was a list a list of SOME of the issues & things to check when working on them

In reality though it keeps coming down to the one biggest factor above all else...

ATTENTION TO DETAIL - can not stress this enough

Upgrades n crap in these poxy toy gun gearboxes is never just a quick bolt on

of various must have go faster parts - they rarely work exactly perfectly in every box

If you change a nozzle - measure old & new lengths

shimming has a foundation of how the pinion & bevel are shimmed

get THAT bit crap it won't matter how smooth the 3 gears spin, it will run poorly/inefficiently

Generic bits n bobs bashed out in China or Hong Kong are made to crap tolerances

No two builds are identical, coz the parts were never that precisely made to begin with

(not really bad, but EVERYTHING NEEDS CHECKING !!!!)

If close attention to detail is applied in first place you will spot issues before or at assembly

Quite a bit of standard stuff in a gearbox can often be kept in many cases

Say a G&G, the cylinder head isn't bad with a bit of ptfe - though cyma is dire loose

Pistons, yeah probably a more durable one after a while when stock one is starting to go

Bushings in Cyma are bloody decent - though G&G soft bronzey bushings replace 12 months

If you keep the juice/amps low then contacts last longer - even a lot longer with a mosfet

Fancy speed trigger crap - personally I like the std one, more ergonomic I think

most speed triggers need a bit of tweaking - bollox to it all imho

Sure if you got a worn jumpy trigger/trolley then yeah you can attempt trigger mods

but really certain mods/upgrades are not worth some of the hassle imho

Especially on a cheapo gun like Cyma CM5xx

The problem with all this tweaking & upgrading crap

Where do you start & where do you stop

Plus quite often it is easy no matter how good you are to make stuff worse

At end of day - it is still a cheapo Cyma - even it shoots 20rps+

So I advise most people not to go nutz upgrading these qwirky cheapo guns

Still do-able but they are qwirky and has caused quite a bit of stress to some

(me included when it don't go to plan and WTF or Dafug becomes your native speech)

Others like G&G's are easier to work on and less qwirky as I said

Cyma gears do run a bit rough imho, if people can't mod box change them to 16:1's

On cyma v2's they have extra re-enforcement on the inside thus have tapered tappet

Cyma v3's just use "regular" tappet plates -none of this Lonex cut out crap (typical)

The v3 spring guide in a v2 gearbox - ehhhh ????

Slightly larger eyelet hole on cyma switch - no biggy

Poxy re-enforced gearbox restricting easy fitment of 13:1 gears - but many are like that

Safety arm has a screw that needs removing prior to open gearbox - no problem but be aware of

The hop entry point is a slither too loose and tapered, not a big deal but I'm nit picking now

(just think the nozzle hole or hop entry is a tiny bit bit bigger, could be a little smaller or more snug)

The box is a tank, it has extra re-enforcement at tappet plate and along cylinder window

You can't just plop a bare piston through the window like on most v2's

Nope it is like a v3, you gotta open the box, fit the bare piston (no piston head I mean), then close up

to test for a binding piston. All due to extra re-enforcement/material they put around it.

Normally on a v2 you can pick say 2 or three bare pistons and check for binding/too sloppy piston etc...

But the box is a tank in its casting/design - probably crap QC control in actual metal composition

But design wise they went nutz on re-enforcing it in places - still need to radius it if you got it in bits

Cyma actually make a few variations in their gearboxes

They make a very similar black v2 box without the extra material around the cylinder window so

bare piston drops in/out easily, think they radius that black box cylinder window too in metal M4's

(still Lonex tappet plate, but the older 7mm bushing non re-enforced MP5 boxes might use std tappet)

Yeah these cheapo cyma boxes have some qwirks and there are some variations in certain guns

WTF - bet ya thought it was all easy peasy - drop in upgrades this teching crap, ergh nope it ain't

Attention to detail is the basis of all this upgrade crappy toy gun stuff

Hopefully " a few pointers " to look into and consider what to look/check for

Are you absolutely sure the SHS piston doesn't bind thus increasing load

Don't know about purple, but sure when I tried a blue it seemed to bind a bit

This is in an APS box but SHS blue metal racks are lovely but bind in many boxes

The piston MUST slide back in a fully enclosed box and MUST FALL when inverted

Often pistons seem to bind at the furthest point back for some reason

(Don't know why but it seems if it will start to bind it will be right at back)

Binding pistons will rob you of rps & fps (sluggish return), increased load/amps/heat etc...

Also some pistons or rather the way their teeth are on the piston can bottom out on full retraction

Right at the final final point of release, the last tooth is set is set slightly different to other pistons

meaning it is trying desperately to pull the last 0.5mm and then slip, but back of piston hit back of box

Not wise to think - I'll file the back of piston, you lose strength on rack/pick tooth

If it seems like it is bottoming out, then file either sector's last tooth or piston rack last tooth

Not a lot, just say 0.5mm to 1mm absolute max, helping it to slip that little bit earlier without bottoming out

Not a problem for me if I Short Stroke a couple teeth on medium barrel setups - never bottom out

MadBull Alien pistons were known to bottom out in some boxes

Piston head, well if you use the bearing inside remember to ensure you use thread lock (blue)

These bearings inside piston often come apart in use - hence thread lock is a must

I & others drop these bearings as they weigh about 4gms or so

Try swiss cheesing 4gms - yeah right, if you can use a nylon spacer @ 1gm that is 3gms saved too

(if you manage to swiss much past 3gms then you are REALLY going some crazy stuff)

I presume you correct AoE - nuff info out there

you lose a bit of fps/stroke but a bearing spring guide helps to replace lost fps (not stroke/volume)

But CM515 should use a full cylinder anyway - bit over volume for 380mm barrel but yeah you are fine

(or a type 1 with slits right at the very back of it, but full cylinder will be ok with a bit extra for 0.25's etc...)

Gears - well cyma stock gears are robust but do run a bit rough, plus the bevel never meshes smoothly

(well imho it always sounds a bit shrilly - the angle meshing with pinion isn't anything like true 90 degrees)

A far fetched example - but if you press the pinion firmly into bevel it "should" be at 90 degrees

Don't know why but the Cyma bevel with its #1 stamped on it often sits at say 85 degrees

So all teeth on both gears never can fully 101% engage

You should also check how well they roll around each other

As well as the motor angle on these two gears before you even bother check height/shimming

Just personally think there are a few basicchecks how some bevels and some pinions all mesh together

think this might be why some gears and some builds sound more shrilly than others no matter what

Some gears are just rougher than others and the cyma gears do run a bit rough imho

BUT - why change the cyma bushings ? They are decent 8mm cross types, filled with grease and all fine

Think SHS bushings are even chunkier tbh, unless you use the black enhanced ones:

https://www.ak2m4.co.uk/internal-parts/bushings-shims/zci-bushings-8mm-enhanced

NB: I'm only guessing they are thinner or protrude less - they look a bit like VFC bushings

Which on a VFC box I had seemed a lower profile or just sat lower than usual

But this could have also been down to the bushing holes or the VFC box itself....

View attachment 33426

But the black VFC bushings deffo didn't sit so proud like regular chunky mofo bushings like SHS

Usually as said....

Bushings protrude further into box, especially SHS ones, had to sand on a table the top bevel one

Quite a while I was sanding round in circles trying to reduce the bevel's SHS bushing just get a 0.10 shim

With Cyma stock bushings & SHS 13:1 you would have likely needed just 0.20mm on top of bevel gear

The spur gear, on SHS you might have run into an issue though

The spur is much more chunkier, even with say 0.1 or 0.15mm shim underneath you may found it tight

I have hadto put a 8mm bearing on top of spur gear to give me a slither more room to shim spur gear

(see first tappet picfor 8mm bearing on spur gear)

The sector gear, you wouldhave roughly spaced it half n half as a guide then checked operating

eg: not rubbing on spur (swirly pattern), or too low that rubs on COL or too high it rubs on case/tappet

(check sector in box when checking tappet operation etc... just in case anything rubs)

This is NOT a shimming guide but more of a rough - VERY ROUGH ball park starting point I found

You need to check motor height properly YOURSELF and determine how the bevel is shimmed !!!!

The trigger/switch/COL stuff well I mentioned that but main issue is getting the fps/seals sorted

This is also not a guide on how to tweak cheapo Cyma M4's either....

It was a list a list of SOME of the issues & things to check when working on them

In reality though it keeps coming down to the one biggest factor above all else...

ATTENTION TO DETAIL - can not stress this enough

Upgrades n crap in these poxy toy gun gearboxes is never just a quick bolt on

of various must have go faster parts - they rarely work exactly perfectly in every box

If you change a nozzle - measure old & new lengths

shimming has a foundation of how the pinion & bevel are shimmed

get THAT bit crap it won't matter how smooth the 3 gears spin, it will run poorly/inefficiently

Generic bits n bobs bashed out in China or Hong Kong are made to crap tolerances

No two builds are identical, coz the parts were never that precisely made to begin with

(not really bad, but EVERYTHING NEEDS CHECKING !!!!)

If close attention to detail is applied in first place you will spot issues before or at assembly

Quite a bit of standard stuff in a gearbox can often be kept in many cases

Say a G&G, the cylinder head isn't bad with a bit of ptfe - though cyma is dire loose

Pistons, yeah probably a more durable one after a while when stock one is starting to go

Bushings in Cyma are bloody decent - though G&G soft bronzey bushings replace 12 months

If you keep the juice/amps low then contacts last longer - even a lot longer with a mosfet

Fancy speed trigger crap - personally I like the std one, more ergonomic I think

most speed triggers need a bit of tweaking - bollox to it all imho

Sure if you got a worn jumpy trigger/trolley then yeah you can attempt trigger mods

but really certain mods/upgrades are not worth some of the hassle imho

Especially on a cheapo gun like Cyma CM5xx

The problem with all this tweaking & upgrading crap

Where do you start & where do you stop

Plus quite often it is easy no matter how good you are to make stuff worse

At end of day - it is still a cheapo Cyma - even it shoots 20rps+

So I advise most people not to go nutz upgrading these qwirky cheapo guns

Still do-able but they are qwirky and has caused quite a bit of stress to some

(me included when it don't go to plan and WTF or Dafug becomes your native speech)

Others like G&G's are easier to work on and less qwirky as I said

Cyma gears do run a bit rough imho, if people can't mod box change them to 16:1's

On cyma v2's they have extra re-enforcement on the inside thus have tapered tappet

Cyma v3's just use "regular" tappet plates -none of this Lonex cut out crap (typical)

The v3 spring guide in a v2 gearbox - ehhhh ????

Slightly larger eyelet hole on cyma switch - no biggy

Poxy re-enforced gearbox restricting easy fitment of 13:1 gears - but many are like that

Safety arm has a screw that needs removing prior to open gearbox - no problem but be aware of

The hop entry point is a slither too loose and tapered, not a big deal but I'm nit picking now

(just think the nozzle hole or hop entry is a tiny bit bit bigger, could be a little smaller or more snug)

The box is a tank, it has extra re-enforcement at tappet plate and along cylinder window

You can't just plop a bare piston through the window like on most v2's

Nope it is like a v3, you gotta open the box, fit the bare piston (no piston head I mean), then close up

to test for a binding piston. All due to extra re-enforcement/material they put around it.

Normally on a v2 you can pick say 2 or three bare pistons and check for binding/too sloppy piston etc...

But the box is a tank in its casting/design - probably crap QC control in actual metal composition

But design wise they went nutz on re-enforcing it in places - still need to radius it if you got it in bits

Cyma actually make a few variations in their gearboxes

They make a very similar black v2 box without the extra material around the cylinder window so

bare piston drops in/out easily, think they radius that black box cylinder window too in metal M4's

(still Lonex tappet plate, but the older 7mm bushing non re-enforced MP5 boxes might use std tappet)

Yeah these cheapo cyma boxes have some qwirks and there are some variations in certain guns

WTF - bet ya thought it was all easy peasy - drop in upgrades this teching crap, ergh nope it ain't

Attention to detail is the basis of all this upgrade crappy toy gun stuff

Hopefully " a few pointers " to look into and consider what to look/check for

Last edited by a moderator:

- Thread starter

- #16

ok thanks for all the response from you i managed to fix it somehow i just put it back together again for the 101st time and it worked perfect. don't know the power because i don't own chrono but its going through cans thats good enough for me. other problem i have is when i drop in 13:1 gears it all locks up

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

ok thanks for all the response from you i managed to fix it somehow i just put it back together again for the 101st time and it worked perfect. don't know the power because i don't own chrono but its going through cans thats good enough for me. other problem i have is when i drop in 13:1 gears it all locks up

Well tbh you need a chrono coz second guessing the fps is never accurate

If you got an SHS HT or RA motor then that should pull anything but the ultra insane

I've messed with original CM515 & more recently CM517 (my favourite)

But rather than waffle on & on about tweaking these cheap guns on the very cheap

You or between a couple of you & any m8's - you need to get a chrono if you are going to mess with stuff

Otherwise you will be guessing at best the final fps

Your gun could be shooting hotter than stock China 400fps model

But SHS motor should still pull a m120 on 13:1's easily

It is a balanced neodym motor, it can pull much more USA fps guns on 12:1's or DSG's

Could be shimming still - honestly this is a bit of a bitch to get anywhere near perfect

but the results speaks volumes in how stuff runs/lasts etc.....

The thing about shimming and is foundation of shimming bevel to pinion....

When you change the bevel in a set - you need to start over again.

Different gears shim up differently - 13:1 spur needing a bearing is one example

BUT SHS bushings and SHS bevels can be way too chunky

(Remember me saying I sanded a SHS bushing for ages to just get a thin 0.1 shim)

Well SHS bevels are quite chunky too, so likely the aprox 0.2 shim is too much

Different bevels are ergh different, look how high the teeth are cut on middle bevel....

So again you can't just assume anything

Now might at a push be able to leave Cyma bevel in there and swap out the spur/sector

(both bevels are 10 teeth, the ratio changes in most sets are down to the spur/sector)

BUT tbh - leave this for another time, it is quite likely your shimming is not 101% perfect

The 13:1 ratio will need pretty good shimming and likely without bearing 13:1 spur is too tight

(As said we are all still learning as we go, save the gears for next time/build)

Besides, with SHS motor in there you got way more snap than stock cyma motor etc.....

The piston could bottom out - but you would think it hit/bottom out on std gears too

I still think this risk could happen in a lot of full stroke builds

more thorough checking & attention to detail

Whoahhhhh - second time in just this response I went off on a raving waffling

In the end you got the thing working of a sort

You probably now understand it isn't quite a simple drop in of upgrade go faster bits n bobs

My first couple of gearboxes were such a disaster they never went back together working

Think it took a while, say 5th or 6th attempt/box before I started to grasp it a little better

And each box/gun can be a bitch in their own ways, we are all still learning imho

In theory, it gets easier and the results are better/smoother with each attempt

Most likely coz you are now not taking a couple of hours

But more like a couple of days coz you are checking & double checking $hit more

(even weeks if waiting on stuff to arrive)

Use it for a while, get it chrono'd/buy a chrono if you intend to get into teching/tweaking

Well done for persevering & getting it running once again, wondered what happened to ya

Well done anyway - I gave up on my first box and bought a new box instead

(I didn't half have the right hump with crappy toy gun bollox gearbox motherf*cker pile of $hit)

Last edited by a moderator:

I now understand why you are called @Sitting Duck, because sod standing and typing all that lot!

Kudos for having the brain, and memory storage to know it all though.

Kudos for having the brain, and memory storage to know it all though.

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

I now understand why you are called @Sitting Duck, because sod standing and typing all that lot!

Kudos for having the brain, and memory storage to know it all though.

Been a chairsofter of late through a few issues health & wealth

hopefully things might be changing and can get off my ar$e with some dosh

(and let others zero their sights on me once again)

I've just broke loads of cheap crap - that's the long/short of it

I know some of what is decent cheap $hit and what is really nasty cheap $hit on some stuff

(usually just the cheapy starter crap that most have issues with "upgrading" - yup done all that)

But don't ask me ANYTHING about high end stuff like TM or GBB coz I really know f*ck all

I just broke loads, read loads, broke more, read more, slowly stopped breaking so much etc....

We all learn from our mistakes - often the best but most costly way of attaining a bit of wisdom

I still have sooooo much to learn - but this sums things up......

Really clever ones wouldn't have broken so many in the first place before finally fixing just one (eventually)

Share: