Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavier Bbs at High Rps

- Thread starter leon1104

- Start date

Adolf Hamster

Supporters

- Feb 1, 2018

- 7,060

- 2,237

yes, but at that rate of fire it's as much about bb quality and magazines

- Thread starter

- #6

I use 0.32 tippmann bbs. I use pts 150 rounds mag and the g&p 130 rounds

my replica is struggling with 0.32 at 30+ rps the spring from the mag is powerful enough. with 0.32 they spit out well.

what kind of fine tuning could I do to make it feed better?

View attachment 57297

View attachment 57298

my replica is struggling with 0.32 at 30+ rps the spring from the mag is powerful enough. with 0.32 they spit out well.

what kind of fine tuning could I do to make it feed better?

View attachment 57297

View attachment 57298

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

increase the tappet travel with a small modest delayer, but one that increases travel

(not just the duration it is held back)

then trim tappet fin slightly to compensate for tappet timing on release

Something halfway between a normal fin & a DSG tappet fin

SHS tappet plates seem to retract a whisker more than others, but need to check for bottoming out on cylinder head on full retraction

add delayer...

it adds a whisker of material around the sector gear's tappet cam to retract say 0.5mm further

combined with a SHS tappet you can get near 1mm extra retraction to help chamber a bb

BUT - there is a fair risk of it hitting the cylinder head at full retraction when these two are combined

some cylinder heads sit further back and you may also need to file cylinder just under the head/tappet area

(to ensure the back of tappet doesn't still hit rim of cylinder)

All of this is checked with sector, tappet, cylinder (& head) in TOP half of box

Also it might be wise to lengthen the channel/groove on underside of tappet plate 1 or 2mm

(or you might find the trigger trolley's lug that the trolley spring sits on breaks off at full auto when pulled

if using a fancy mosfet like Titan then there is no need to mod tappet grooves no trolley - duuhh)

A bit of pissing about trying to stretch the length of tappet retraction, so nozzle moves further back

thus gaining a bit extra wiggle room for nozzle to clear & chamber a bb better at speed

However, you are trying to feed bb's that are over 50% heavier than 0.20's so you still might struggle

even after all this you might find you have to drop to say 0.25's or 0.28's

but yeah, glad you are not local to me

(not just the duration it is held back)

then trim tappet fin slightly to compensate for tappet timing on release

Something halfway between a normal fin & a DSG tappet fin

SHS tappet plates seem to retract a whisker more than others, but need to check for bottoming out on cylinder head on full retraction

add delayer...

it adds a whisker of material around the sector gear's tappet cam to retract say 0.5mm further

combined with a SHS tappet you can get near 1mm extra retraction to help chamber a bb

BUT - there is a fair risk of it hitting the cylinder head at full retraction when these two are combined

some cylinder heads sit further back and you may also need to file cylinder just under the head/tappet area

(to ensure the back of tappet doesn't still hit rim of cylinder)

All of this is checked with sector, tappet, cylinder (& head) in TOP half of box

Also it might be wise to lengthen the channel/groove on underside of tappet plate 1 or 2mm

(or you might find the trigger trolley's lug that the trolley spring sits on breaks off at full auto when pulled

if using a fancy mosfet like Titan then there is no need to mod tappet grooves no trolley - duuhh)

A bit of pissing about trying to stretch the length of tappet retraction, so nozzle moves further back

thus gaining a bit extra wiggle room for nozzle to clear & chamber a bb better at speed

However, you are trying to feed bb's that are over 50% heavier than 0.20's so you still might struggle

even after all this you might find you have to drop to say 0.25's or 0.28's

but yeah, glad you are not local to me

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

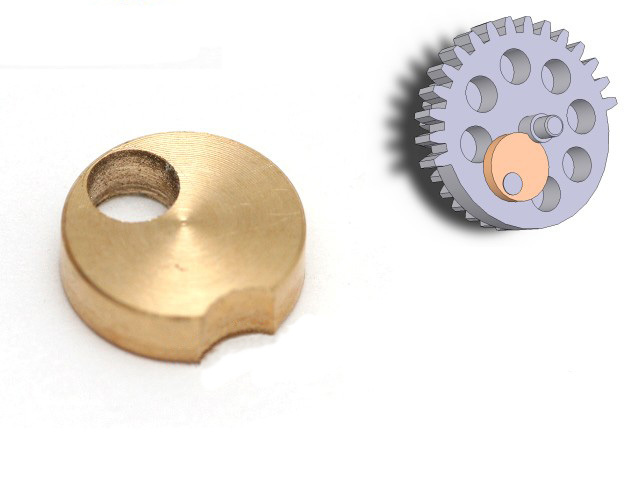

Delay clip - the type I posted in the pic, different makes but in essence that type

it has a complete hole in the clip and at the point that slips over the tappet cam

it adds a thin bit of material just in front of the sector's cam that other delayers do not

that in turn adds to tappet retraction as well as a slight delay like other clips

The trimming of fin - when you add a delayer the nozzle gets delayed from being returned

normally in a 20rps gun it will matter little but at 40rps it might effect tappet timing

So by trimming the fin, you are compensating for delayer releasing the tappet later

Doesn't that contradict the point of the delayer - no

the tappet is retracted for longer still but its final release is not delayed much later with full fin

The retraction starts slightly earlier but trimming the fin ensures it isn't delayed too much in terms of timings

& besides with a full, the tappet return is a more gradual return - but @ 40rps the operation of it all is far from gradual

As the sector's tappet cam passes the 9 o'clock, well I'd say about 9:30 the tappet nozzle is starting to return

(if you look at most tappets, the shape of the fin & the true effect it has on nozzle retraction)

Anything after that point the tappet is returning/nozzle closing & is now attempting to chamber a bb that might

have slipped in front of the nozzle - the opportune moment to improve the feeding has now passed

The important thing is to make sure you can increase the nozzle retraction where possible

Pople think a long delayer is the be all - but it needs to retract enough so a bb can chamber

or at least 6mm space in front of nozzle to chamber the 5.95mm bb

if by adding delayer you add 0.5mm & with SHS tappet retracting more you have now 7mm space

a bb will chamber better with more space and a slightly longer duration of it being " open "

But as explained the final stages of a full fin might delay the nozzle returning in time for piston/compression at speed

Different tappet plates blah blah blah....

SHS retract more I have found, but a very flexible & the front is not always a true 90 degrees

so need to bend it to 90 degrees - use hot water, leave it for a minute then bend to straighten it

see here for bent tappet fronts...

https://www.retroarms.com/news/tappet-plates-and-how-they-are-different

The SHS tappet "groove" where nozzles sits is not completely centered, the nozzle sits slightly further back

as the ridge in the nozzle channel is slightly further back than complete center at 50/50

and due to this nozzle sitting slightly further back many sand the front slightly to ensure nozzle is forward more

(though this nozzle return point has no effect on feeding/chambering bb's - just ensures it seals against bucking)

Tappets vary as the link says and plays a significant role in how well the bb is efficiently chambered into hop unit

delayers can help, but if not careful they can complicate & even mess with timings (hence minor trimming of fin for high speed)

that is a before/after of what I do on V2's where you have less tappet retraction than on v3's

View attachment 57322

as on v3's the resting point of the tappet is further forward, thus the total tappet travel is greater

(so you effectively have more wiggle room to begin with on v3 than v2's)

Most tappet plate fronts are about 3mm, so you have 10mm - 3 = 7mm nozzle retraction max on v2

or on a v3 you have at least 11mm which means you have 8mm nozzle retraction

(sanding tappet front on SHS to say 2.5mm only assists sealing against bucking - does nowt for feeding)

With delayer I suggested, you retract the tappet a whisker more, the trimming of fin is just trying to keep the return timing about the same - especially in higher speed builds as max retraction was attained at say 9:30 so anything beyond the 9:00 or deffo 8:30 o'clock is nozzle returning

On DSG's with a tiny fin, you can't add a delayer at all, the only thing you do with a DSG is add a small sleeve(s) like ones fitted to the gear axles

a 4mm OD x 3mm ID sleeve giving 0.5mm increased tappet retraction x 2 over the two tappet cams on the DSG

(or 4.5mm OD x 3mm ID giving 0.75mm further retraction, 5mm OD is risky)

Point being you need to get max retraction where ever possible, check it doesn't hit cylinder/cylinder head an increased retraction

(mod where needed if required to avoid snapping tappet or increased wear straight away)

Hopefully the duration at the final retraction in improved to assist feeding but not mess up timings (trim fin slightly)

That is about all you can do, but YOU have to check all this in operation & its efficiency in top half of box

Of course you could just use a shorter nozzle that would assist feeding by increasing clearance for bb

but you'd likely lose a bit of fps from poor seal at bucking - so it can be tricky getting it to operate perfectly & completely efficiently at higher speeds

Plus already said you are pushing it trying to chamber 50% heavier bb's at 40rps than lighter 0.20's or 0.25's

Typo's aside (can't be arsed)

I'm assuming you are a SSG likely SS a few teeth etc... as that is what I based the delay clip response on

(guessing 12 or 13:1 with 35k motor-ish on 11.1v 30c etc... on a 328fps build blah blah blah)

But that aside if you are using a DSG build I included the option to add a tiny delay & increased retraction to DSG

it has a complete hole in the clip and at the point that slips over the tappet cam

it adds a thin bit of material just in front of the sector's cam that other delayers do not

that in turn adds to tappet retraction as well as a slight delay like other clips

The trimming of fin - when you add a delayer the nozzle gets delayed from being returned

normally in a 20rps gun it will matter little but at 40rps it might effect tappet timing

So by trimming the fin, you are compensating for delayer releasing the tappet later

Doesn't that contradict the point of the delayer - no

the tappet is retracted for longer still but its final release is not delayed much later with full fin

The retraction starts slightly earlier but trimming the fin ensures it isn't delayed too much in terms of timings

& besides with a full, the tappet return is a more gradual return - but @ 40rps the operation of it all is far from gradual

As the sector's tappet cam passes the 9 o'clock, well I'd say about 9:30 the tappet nozzle is starting to return

(if you look at most tappets, the shape of the fin & the true effect it has on nozzle retraction)

Anything after that point the tappet is returning/nozzle closing & is now attempting to chamber a bb that might

have slipped in front of the nozzle - the opportune moment to improve the feeding has now passed

The important thing is to make sure you can increase the nozzle retraction where possible

Pople think a long delayer is the be all - but it needs to retract enough so a bb can chamber

or at least 6mm space in front of nozzle to chamber the 5.95mm bb

if by adding delayer you add 0.5mm & with SHS tappet retracting more you have now 7mm space

a bb will chamber better with more space and a slightly longer duration of it being " open "

But as explained the final stages of a full fin might delay the nozzle returning in time for piston/compression at speed

Different tappet plates blah blah blah....

SHS retract more I have found, but a very flexible & the front is not always a true 90 degrees

so need to bend it to 90 degrees - use hot water, leave it for a minute then bend to straighten it

see here for bent tappet fronts...

https://www.retroarms.com/news/tappet-plates-and-how-they-are-different

The SHS tappet "groove" where nozzles sits is not completely centered, the nozzle sits slightly further back

as the ridge in the nozzle channel is slightly further back than complete center at 50/50

and due to this nozzle sitting slightly further back many sand the front slightly to ensure nozzle is forward more

(though this nozzle return point has no effect on feeding/chambering bb's - just ensures it seals against bucking)

Tappets vary as the link says and plays a significant role in how well the bb is efficiently chambered into hop unit

delayers can help, but if not careful they can complicate & even mess with timings (hence minor trimming of fin for high speed)

that is a before/after of what I do on V2's where you have less tappet retraction than on v3's

View attachment 57322

as on v3's the resting point of the tappet is further forward, thus the total tappet travel is greater

(so you effectively have more wiggle room to begin with on v3 than v2's)

Most tappet plate fronts are about 3mm, so you have 10mm - 3 = 7mm nozzle retraction max on v2

or on a v3 you have at least 11mm which means you have 8mm nozzle retraction

(sanding tappet front on SHS to say 2.5mm only assists sealing against bucking - does nowt for feeding)

With delayer I suggested, you retract the tappet a whisker more, the trimming of fin is just trying to keep the return timing about the same - especially in higher speed builds as max retraction was attained at say 9:30 so anything beyond the 9:00 or deffo 8:30 o'clock is nozzle returning

On DSG's with a tiny fin, you can't add a delayer at all, the only thing you do with a DSG is add a small sleeve(s) like ones fitted to the gear axles

a 4mm OD x 3mm ID sleeve giving 0.5mm increased tappet retraction x 2 over the two tappet cams on the DSG

(or 4.5mm OD x 3mm ID giving 0.75mm further retraction, 5mm OD is risky)

Point being you need to get max retraction where ever possible, check it doesn't hit cylinder/cylinder head an increased retraction

(mod where needed if required to avoid snapping tappet or increased wear straight away)

Hopefully the duration at the final retraction in improved to assist feeding but not mess up timings (trim fin slightly)

That is about all you can do, but YOU have to check all this in operation & its efficiency in top half of box

Of course you could just use a shorter nozzle that would assist feeding by increasing clearance for bb

but you'd likely lose a bit of fps from poor seal at bucking - so it can be tricky getting it to operate perfectly & completely efficiently at higher speeds

Plus already said you are pushing it trying to chamber 50% heavier bb's at 40rps than lighter 0.20's or 0.25's

Typo's aside (can't be arsed)

I'm assuming you are a SSG likely SS a few teeth etc... as that is what I based the delay clip response on

(guessing 12 or 13:1 with 35k motor-ish on 11.1v 30c etc... on a 328fps build blah blah blah)

But that aside if you are using a DSG build I included the option to add a tiny delay & increased retraction to DSG

Last edited by a moderator:

Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

Don't know what you have don but at least the silly text script has ceased

Don't know what the caps are for - but you asked so I answered

admit there is a translation issue here perhaps, but hopefully you might figure out my suggestions

though very involved (as usual with most of my replies), you did ask for any kind of fine tuning etc...

best wishes

Share: