uniweekendwarrior

Members

- Aug 13, 2014

- 175

- 6

- Thread starter

- #41

Careful you lose Auto for good until you buy a new selector plate

http://www.airsoftsociety.com/threads/how-to-semi-lock.132570/

Pico mosfet is perhaps easier or Nano than making just one DIY one up

(but then you will need a soldering iron anyway - so what is a bit more soldering to build your own)

http://www.patrolbase.co.uk/airsoft/gate-picossr-3-aeg-micro-mosfet-unit.htm#.Wdu4uVtSzIU

or

http://www.patrolbase.co.uk/airsoft/gate-nanoasr-3rd-gen-advanced-solid-state-relay-mosfet.htm#.Wdu4aVtSzIU

When the old mosfet blew - ^ these ^ are what the owner should have replaced it with

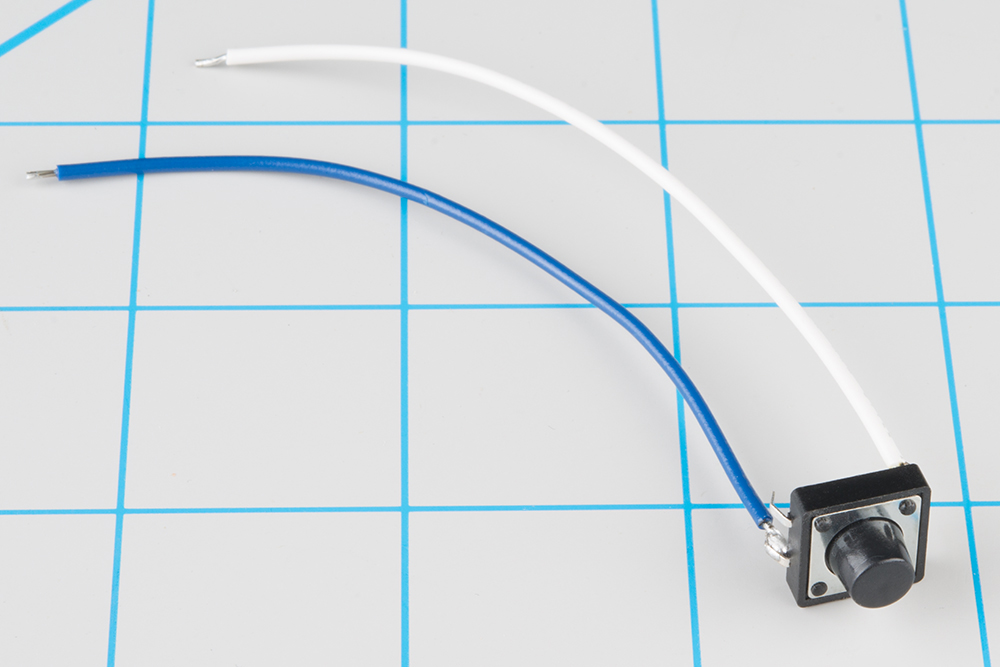

the extra switch - a cheap tiny tactile switch with wires hidden/glued inside a fixed m4 DMR stock

just basically a way of making it cycle on auto if it ever got stuck

return to dead zone/safe zone simply pop mag, click extra trigger inside stock/magwell if feeling clever

gun cycles on auto clearing lockup without needing to strip or try to pick AR latch etc....

TBH - f*ck knows why when companies make a DMR type gun they don't f*cking do this anyway

Thank you very much I'll put a parts list together for him to buy.

If I get stuck I'll be back to pick your brains.

I expect they don't do it because of cost. Although it may save them money on warranty returns.