Hold up !!!!

this is an ongoing issue is it not ???

Now it "seems" that the cyma MP5 nozzle is a 21.4 ish nozzle...

https://www.airsoftforum.com/topic/241139-massive-air-seal-nozzle-leakeage-on-a-cyma-mp5sd/

so it seems 21.4 to 21.5 ish is required...

(also heard a Galaxy MP5k nozzle likes a SHS M4 too

but the "shoulder" of red SHS M4 is too fat so needs modding to nozzle shoulder

or modding/widen the Galaxy hop entry so chubby nozzle can operate smoothly)

in other words not all MP5 nozzles are the usual MP5 length

(different guns makes/hops work with different nozzle lengths than 1 size fits all)

Also different nozzles sit differently or better/worse on some tappets...

the clear cheapo cyma tappet is loose as f**k with a red SHS m4 nozzle

(hence me using a SHS tappet but needs modding up front with cut outs for cyma box)

What I might suggest is grab a SHS V2 tappet as these tappets retract most

might be a bit bent, so straighten the right angle up front in hot water to true 90 degrees

sand the front of tappet plate a bit, mod the sides up front to work in Cyma box

if you sand the tappet front edge on a table with emery paper it will return a whisker further

then you could carefully and very lightly sand the red M4 nozzle a whisker - just a whisker

but as you sanded the front it will return to seal on hop unit/bucking...

The new SHS tappet should retract further and allow a bb to chamber on a lightly sanded M4 nozzle

(that still returns to seal as tappet front is sanded a bit)

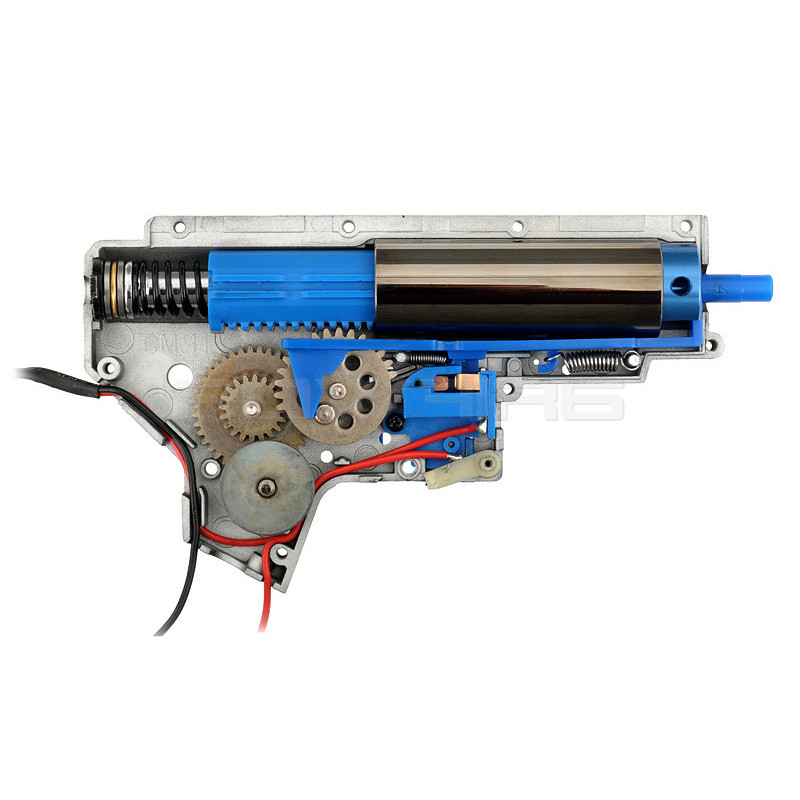

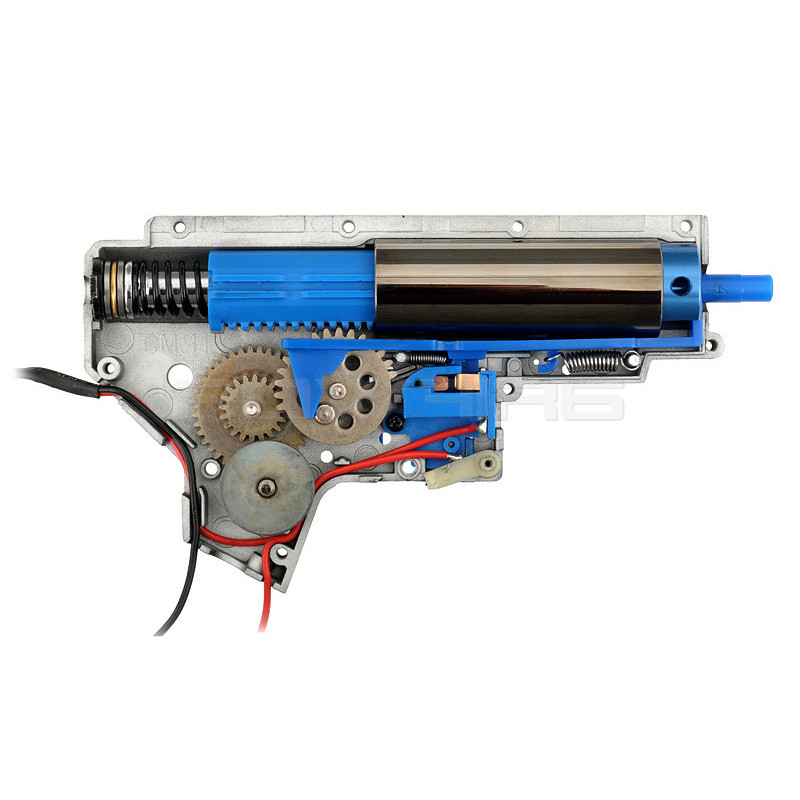

check for fin hitting axle of sector as in pic

you may need to file it very slightly and very carefully smack bang in line with axle

don't worry about not retracting long enough - delayers are not the solution to all feed issues

a friggin' DSG fin is so short it retracts for a split second then returns...

It is mostly about ensuring the tappet window is correct that is pulls back enough to chamber

allowing a sprung loaded bb to slip in and chamber to bucking etc....

It don't matter shit if you got a mega delayer - if there is only 5.5mm room

it will never chamber a 6mm bb past the nozzle

so a long nozzle throws stuff out and seals great but feeding is shit

or a shorter nozzle feeds great but seal is crap

a worn fin, incorrect nozzle, protruding bucking lips and f**k knows what else will cause feed issues

and V2 boxes have less overall retraction than V3's so on V2's the tappet window is more critical

Yeah I'd be tempted to get a SHS v2 tappet, start modding the cutouts for Cyma box

sand the front, check it is straight and 90 degrees, very very slightly sand the SHS M4 nozzle perhaps

open box up, check & mark where fin meets sector axle - file with tiny round craft file at exact point

check the tappet fully returns to front of box clearing the axle of sector as in pic

Also check the tappet in TOP part of box with cylinder head, sector gear etc...

check it doesn't bottom out on full retraction with cylinder head

(SHS tappets do retract more)

if delay clip is still on sector, check you don't feel a "bump" which is the delayer clip bumping the underside of tappet runner

right underneath as the cam/delayer starts to engage the top of fin...

if you feel this "bump" or slight resistance, then you need to lightly file the area about 1~3mm just in front of top of fin

on the underside of tappet runner by the fin...

BUT ONLY do this IF you feel a bump or resistance when testing in top half of box

*** NB ***

When I say 1~3mm I'm talking about the AREA or POSITION of AREA 1~3mm in front of fin

NOT file off up to 3mm in depth - there will hardly anything left and fin would just tear off

just a very light file around the few mm's just in front of tappet runner in front of fin

Literally a very small filing & sanding just where cam might bump the runner

If no "bump" is felt when testing it top of box - then don't worry about it, but important you check

Test the tappet operation in top half of box - sounds weird but just do it

When you test in the lower half there is too much play with sector wobble to truly check stuff

So checking the final tappet retraction is much more accurate in top half of box

(though you can't quite see the cam/fin operation, you see the full travel and feel for "bump")

When all that is done, ensure the fin doesn't get stopped by axle, mod if needed (quite likely)

then ensure smaller diameter shims are used as less likely to impede fin than jumbo shims

IF tappet is risking bottoming out on cylinder head....

and IF you used one like this....

Look carefully at bottom of head and there is a small ridge....

Take off the o-rings, plop on a shitty old nozzle

then file off that curved ridge at bottom CAREFULLY

clean up and refit o-rings etc...

Bit of f**king about but will gain you a potential extra 0.5mm to say 0.75mm or so space

so tappet won't bottom out of cylinder head when retracting to its furthest point

(the cylinder itself might be close to hitting the back of tappet but check in top box)

if cylinder is just starting to touch the tappet, you could just file it very very slightly

so that when you test (again in top half of box) it moves way way back

and the whole operation is met with no resistance, no "bumps" or bottoming out

and full complete return to front of box coz you carefully filed the fin by sector axle

THEN you have a tappet that retracts as far back as possible & smoothly returns fully

so you therefore have the largest tappet travel to give you a bigger tappet window

With the correct nozzle in there, you should get a great seal and reliably feed bb's even on so-so mags

THAT is about the best advice of everything I check for and nigh on every trick I have used to get max retraction etc...

BUT as always it is down to YOU to check all this crap out and see if it all operates smoothly and effectively etc....

The SHS tappet will retract the most

the round delayer I used in pic is brill, retracts more coz it has a bit of material over sector cam

BUT using this delayer on SHS tappets that retract more does often mean it can bottom out and risk bumping tappet runner underneath

It also retracts so much it bottoms out so need to give it some room to fully retract where ever possible

But after all this f**king about, plus the modding for Cyma v2 boxes

you will gain about 1mm extra retraction or just over that will greatly assist if not eliminate any feed issues

(at least from tappet/nozzle retraction - w@nky bucking or hop or assembly alignment is another issue)

As the V2's have about 1mm overall less tappet retraction than a V3

when stuff starts wearing like the fin, or nozzle spec or tolerances go just a tiny bit out of whack...

you get fps loss or pi$$ poor feeding coz the allowance for nozzle clearing & sealing is so close

As said if fin is worn, nozzle way too long, delayer will do little

if fin hits axle, the tappet won't 101% fully return to seal

so might need modding at axle area to ensure it returns

if you look at Cyma's blue tappet you see they chopped the axle area...

A SHS will need modding but found they retract a whisker more than other tappets

so check some $hit out, do some tests

order up a SHS tappet, use SHS M4 nozzle and do some tiny modifications for max tappet travel

You MUST check for bottoming out coz if you allow it you will lose a whisker of retraction

plus increased wear on fin or worse if tappet break/failure - so check $hit carefully !!!

best of luck