well just finished putting everything back together, glad i had a mix of pistons and heads as some did not slide easy or give good compression, need to strip it back apart again as it is running way to hot for my uk site - results using a 30k motor on 16:1 gears and a 7.4 lipo on a sp100 spring with my 455 barrel gave me 375 fps and 16 rps air seal seams good as the fps only went from 374 - 376 over about 40 shots. might pop in the 40k motor again and see if the FPS is closer to 20 / 22

i need to get the fps down to around 345 - so should i get a sp90 spring or remove the 5mm nylon spacer from the piston head ? i am not sure but i think removing the spacer might only drop me about 15 fps just want to avoid stripping it apart another 20 times !

Woah - that is quite a difference to what you had.....

FPS 345 to 375 is a 30fps jump, you must have improved the air seal a bit with different piston head/o-ring

Plus is it the same spring and is it an irregular spring - tighter coils at one end than even all the way ???

If it is an irregular spring - did you fit it in reverse ???

The tighter coils go at the back of box on the spring guide

if you fit tighter coils up at front of piston - this can increase fps by about 10-12 fps I have found

I'm assuming you already had a bearing spring guide at the back previously this adds about 15fps or so over std guide

(normally fitting a bearing spring guide & losing a smidge when correcting AoE kind of cancels each other out)

The same spring - which quite likely could be a m110 faded to m100 will give out about 350-375 in a AK

But same spring will give 300fps in a mp5k with much shorter barrel - so a m100 rarely hits 328fps in every gun

Factor in final spring compression which with bearings/spacer plus bearing guide will be 2 x 4.5mm extra compression

(compared to std spring guide and zero piston spacer/bearing/spring mount etc...)

Each tooth is about 3mm so you have extra 3 teeth compression but you can't really short stroke (maybe one tooth at a push)

YES you are correct the spacer will drop about 15 fps - same as a bearing spring guide

Also is the spring fitted the correct way - tight coils at the back of box if an irregular spring ???

Yes you have gained 30fps maybe this was say 20 fps increase improved seals

10fps boost from either back to front spring or crazy light piston - though think 5fps myself on lightened piston

The ROF though - WTF has happened to that ???

First of all you are on bearings which will give you an extra 1 or two rps perhaps over bushings

Secondly you are using 16:1 over 18:1 gears - which though not true 16:1 but 17.25:1 ratio

You should still get about an extra 8% over std gears rps wise

On a great day, perfectly shimmed, lovely spinning gears on bushings or mix of bushing/gears

with thicker 16awg - and the final quality of wire/its CSA/how many breaks in wiring loom deans blah blah blah

But on a great - all boxes ticked 30k motor 18:1 setup on a 350mm barrel 350fps you should be @ 19-20rps

So my main hunch is that 30k is not quite 30k - more like 25k tops imho

If your fps wasn't so high I'd say go back to the 40k motor but you gotta open the box to drop fps

I mean yeah - whack in the 40k motor and you should get around 24rps to 26rps

But still gotta look into dropping fps - but give a go by all means....

If you can use the 40k motor as is for now to get say 24rps then great

Did say just get a SHS or RA motor would be an option at the beginning....

BUT the bearing came adrift, so you could have still got a fps boost when you fixed up the box anyway

So no point blaming this or that or should/shouldn't have done that - results do vary a smidge on each build/opening

Try the 40k motor with the 16:1 gears

13:1 gears + 30k max motor

std or 16:1 gears + faster motor - so go with this perhaps

The fps - you have numerous options

SP90 = M100 or a m95 if you got awesome seals atm

cut a couple of coils - don't like this coz it is still a bit of guesswork plus need to crimp flat & finish end of spring off

remove piston spacer and perhaps the bearing spring guide at back going to std spring guide

would be wise to still have a bearing somewhere for potential spring twist but need a gun with UK limits to use

maybe remove just one - say spacer and rotate the bearing collar or something to use existing M3 piston head bolt

(or shorter M3 bolt & washers etc....)

ensure the spring itself is fitted tighter coils at rear - this is an easy mistake and can make a 10fps difference

So if the spring is ar$e about face you could fit it correctly and tbh use std spring guide.....

This should get you say 25fps less = just over 350fps

You got a metal rack piston, leave gun half cocked or pre-cocked overnight is just over 350fps

(assuming your chrono is correct as sites chrono is what they decide upon btw so careful if you got 349.9999fps)

OK spring twist OMG - relax, in 6 months time your gun will drop a bit fps wise no doubt...

when it hits 320-330fps from wear on seals or if spring fades a bit - pop the bearing spring guide = 15fps extra

Problem buying another spring is you then start with a blank sheet of paper....

You do not know for sure what exactly your present spring is to begin with - likely a m102.5 ish

Then the new spring could be this or that....

An APS UAR gun has one of the quickest spring change I know of - in about 90 seconds you chrono two springs

It is a great way of comparing two springs to greatly reduce the guesswork

Though not to be taken 101% exactly as it has a 400mm barrel aprox it is more the comparison it offers

So the difference should kinda correlate if not exact fps in a shorter gun then aprox percentage wise

Alas all this maths bollox never quite works out 101% as intended but hopefully gives a modest guide that just pot luck

Yes you could try a m95-ish spring and it could work out about right....

I'd consider working with existing spring one last time if you check to see if losing a spacer/guide & spring correctly fitted

If still a nightmare then look at hacking or buying another spring

It isn't the cost - a tenner is nothing but more you could still be guessing the final results and another strip down

I'd try the 40k motor to see the rps on the 16:1 set - should hit 25rps, if so the new motor is 25k max imho

(use new slow motor with 13:1 gears blah blah blah)

then open box - check spring is fitted correctly, look to lose bearing spring guide and spring correct way

(tighter coils at rear)

If spring is fitted correctly then you would have to lose bearing spring guide AND spacer tbh....

However - there is also another possible reason for fps change if you changed piston head and cylinder head....

Is the AoE still corrected properly - on some silent heads that are concave/convex shaped you can't really correct AoE

Well not like usual heads - now if the AoE is no longer corrected like before you have a slightly longer stroke perhaps

The longer stroke increases fps - we lose about 10 to 15fps when correcting AoE but bearing spring guide compensates etc...

If the AoE is now slightly under corrected from new heads etc... then the stroke will add a bit onto fps too

How do you correct AoE on those heads - with a spacer behind the piston head - say a 15mm x 2mm/3mm tap washer

Won't this bottom out - no coz actual piston retraction does not change the piston head stroke is shortened a whisper

This is now clutching at straws but trying to cover every possible aspect of how the fps has altered

Most likely down to great seals etc.... but just slight alterations to present setup can make a difference

I'm just trying to list everything to consider before you end up launching the thing down the garden

(been there quite often - actually very often if I'm honest)

The fps if still the same spring could be fitted back to front and maybe a couple of other things like heads chaged

The motor is way out imho - think it is 25k - try the 40k first and see what you got...

Have a think exactly what you have done and give yourself a bit of time to reflect what exactly changed fps wise

Sorry for massive waffle and no doubt continual repeating myself but trying to cover everything

hopefully one last opening and attempt will achieve the rps & fps you need to get to

AFTERTHOUGHT....

If you are on the 16:1 set then you could or should be able to use old std sector gear...

It "should" be compatible with the 16:1 spur gear and if it runs smoothly

and the last tooth on sector is not a fat final release tooth...

You "could" experiment with ShortStroking the old 18:1 sector gear one tooth if you are stuck

Note some sectors have a fatter final release tooth on sector and so you you need to grind off on piston

But if all the teeth on sector are exactly the same then you can leave the piston's teeth untouched

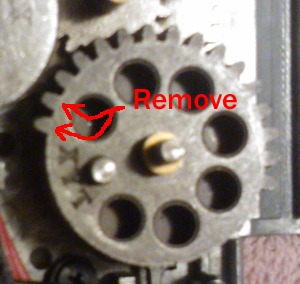

pic says a thousand words - see the sector on the right - the fat final tooth is what I mean....

IGNORE THE SECTOR ON LEFT - this was ShortStroked incorrectly

They took off five teeth (jeeez) mostly on the WRONG SIDE which screws up tappet timing

(16 - 5 = 11 ffs, a dsg has 8 or special dsg has 9 teeth but fires twice so could have gone dsg)

(you have to shorten tappet fin and increase tappet spring compression etc.. to compensate for this)

You take off a tooth or two on the other side first like this....

I messed up following an incorrect guide when I first started

not saying going nutz short stroking coz you need full stroke or nigh on for AK47

but you "could" perhaps experiment on old std 18:1 sector is what I'm saying with 16:1 set

(you get the idea of what I mean - can't do this on 13:1 coz sector is different)

Just be careful if std sector is chunky last tooth as you would have to remove the piston's last tooth

(not worth it but just a thought if the sector's teeth were all the same blah blah blah...)