Pseudotectonic

Members

- May 7, 2022

- 472

- 307

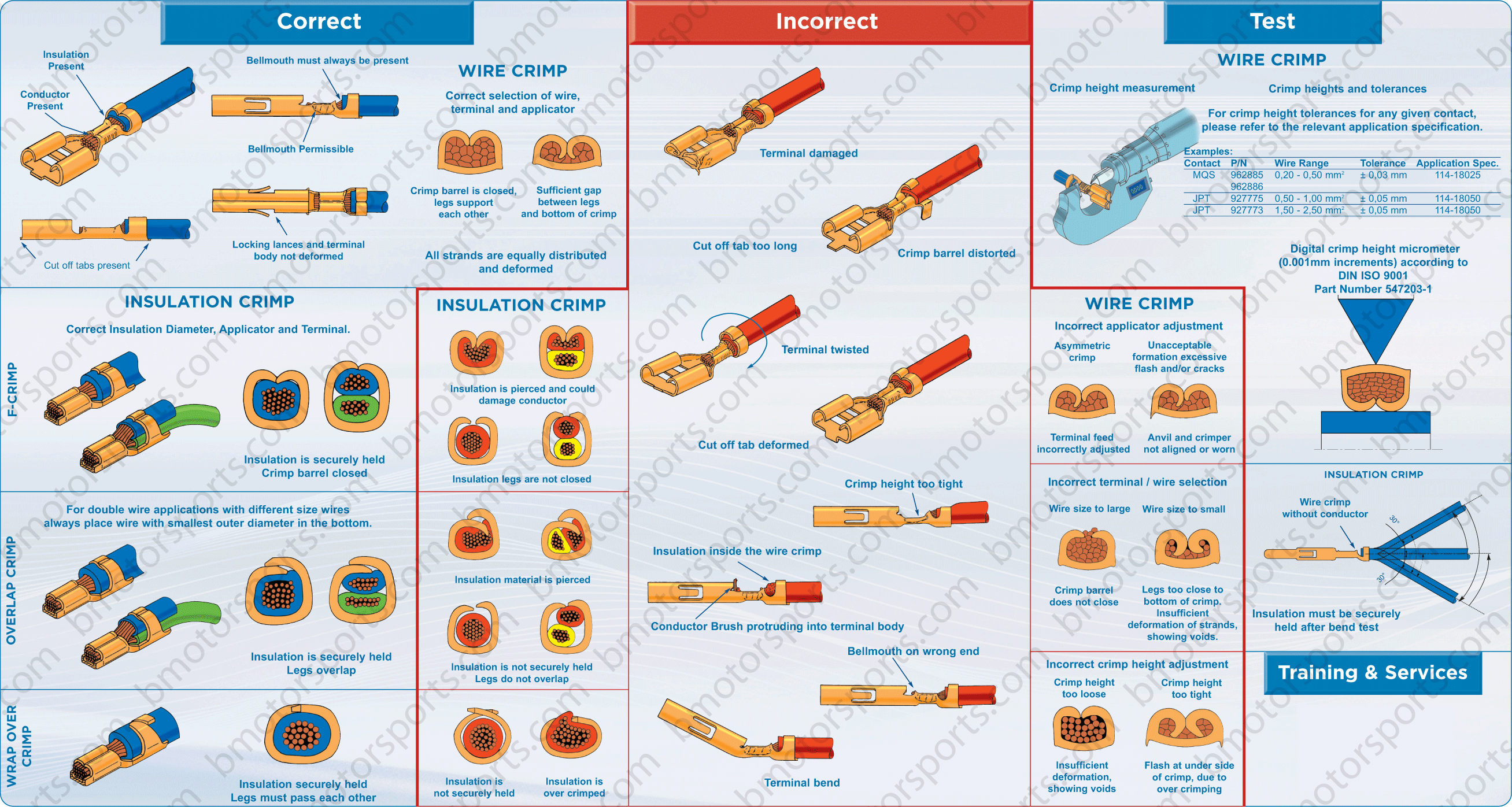

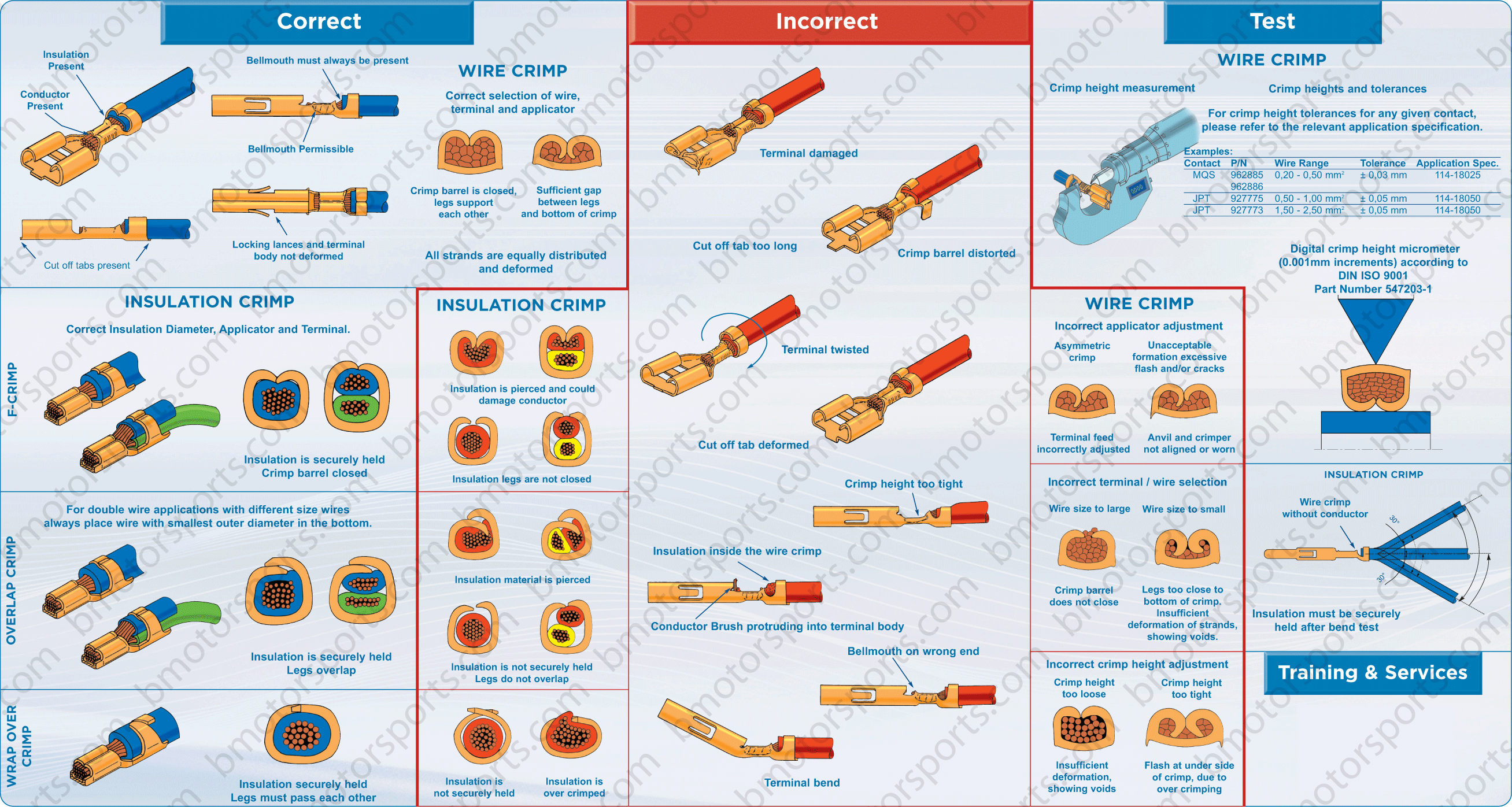

The ideal is the two sides bending 180 degree back into the wire

But with needle nose pliers an overlap is probably more practical (unless you have the perfect crimping tool it will be impossible to achieve the correct 180 bend)

And arguably airsoft is not very critical application, so as long as it is secure enough, it is secure enough

Nah multi-strand is not the problem. Don't tin it, it is going to be worse because tin cannot deform like copper and it will actually make it worse

Also note there are two pairs of "legs", one is for the wire jacket which is just for the mechanical stress relief, and another pair for the actual copper wires and this is for doing the actual work of conducting electricity

But with needle nose pliers an overlap is probably more practical (unless you have the perfect crimping tool it will be impossible to achieve the correct 180 bend)

And arguably airsoft is not very critical application, so as long as it is secure enough, it is secure enough

Is the fact I've got a multi-strand core the problem? Do I need to tin it with my soldering iron for best results?

Nah multi-strand is not the problem. Don't tin it, it is going to be worse because tin cannot deform like copper and it will actually make it worse

Also note there are two pairs of "legs", one is for the wire jacket which is just for the mechanical stress relief, and another pair for the actual copper wires and this is for doing the actual work of conducting electricity