Sitting Duck

Supporters

- May 11, 2014

- 4,894

- 1,735

Ahhh - well you got travel on selector plate:

Left & it engages safety arm to stop trigger being pulled

Middle = semi but COL lever is down to operate correctly with spring returning it

Right = COL is raised right up for auto as explained

Normally most stuff or bits do work ok with a smidge of tolerance

However some selector plates like most stuff, certain ones work better/worse than others

yes M4 & MP5's are different plates but I'm saying just M4's can vary

the "arch" or "horseshoe" exact location can vary a bit from one to another though not too common

but in cases it can throw stuff out and the smooth selection can be thrown right out

After a few headaches after more headaches you learn to make careful comparisons between parts

replace a badly worn part or broken part with just anything can get you into more grief...

If you compare parts as a routine you may find before fitment - " well that ain't right.... "

sadly in your case there wasn't a selector plate there to compare

but check it operates left/center/right as described

soz - it is a bigger pain to get a completely newly built box running than a quick fix of existing box

as you really really need to triple check everything works 101% as it should - difficult if all parts are newly built

so we learn by mistakes & obtain a tiny bit more wisdom - f*cking PITA way of learning but you fully learn imho

back on topic - yeah could be a worn COL too - sounds like it was an older box ya got hold of

so who knows it could be worn on COL - ah well you got some pointers and getting a steep learning curve

no doubt it may need stripping again to check the operation - rolling sector back as described etc....

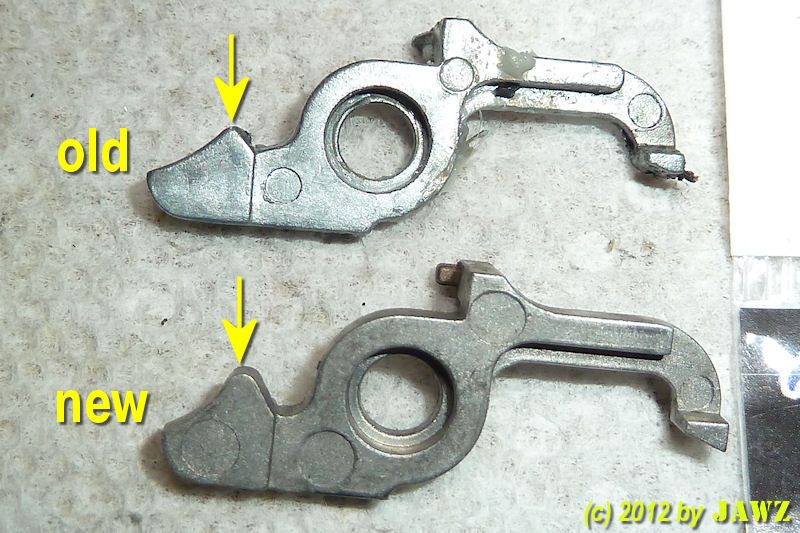

then compare the COL's old & new if you feel it needs replacing - compare side by side:

Left & it engages safety arm to stop trigger being pulled

Middle = semi but COL lever is down to operate correctly with spring returning it

Right = COL is raised right up for auto as explained

Normally most stuff or bits do work ok with a smidge of tolerance

However some selector plates like most stuff, certain ones work better/worse than others

yes M4 & MP5's are different plates but I'm saying just M4's can vary

the "arch" or "horseshoe" exact location can vary a bit from one to another though not too common

but in cases it can throw stuff out and the smooth selection can be thrown right out

After a few headaches after more headaches you learn to make careful comparisons between parts

replace a badly worn part or broken part with just anything can get you into more grief...

If you compare parts as a routine you may find before fitment - " well that ain't right.... "

sadly in your case there wasn't a selector plate there to compare

but check it operates left/center/right as described

soz - it is a bigger pain to get a completely newly built box running than a quick fix of existing box

as you really really need to triple check everything works 101% as it should - difficult if all parts are newly built

so we learn by mistakes & obtain a tiny bit more wisdom - f*cking PITA way of learning but you fully learn imho

back on topic - yeah could be a worn COL too - sounds like it was an older box ya got hold of

so who knows it could be worn on COL - ah well you got some pointers and getting a steep learning curve

no doubt it may need stripping again to check the operation - rolling sector back as described etc....

then compare the COL's old & new if you feel it needs replacing - compare side by side:

Last edited by a moderator: