-

Posts

26 -

Joined

-

Last visited

-

Feedback

0%

Content Type

Profiles

Forums

Buy a Patch

Classifieds

Everything posted by Ben Savage

-

Upgrading Cyma M4 - Motor/gearbox sound issues

Ben Savage replied to Ben Savage's topic in Electric Guns

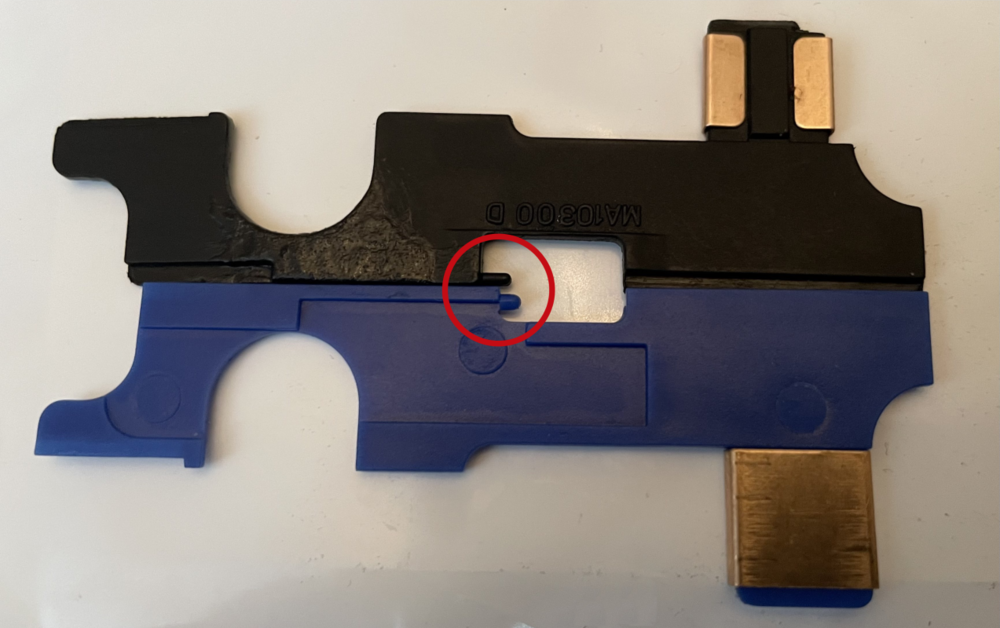

This morning I had a delivery of the parts which I thought would get everything fixed, and thankfully the piston now fits much better. I also had a look at the new piston width info in the descriptions, and I was unlucky enough to have bought the widest piston that there was, so I likely could have tried a different XT piston. The selector plate on the other hand doesn't seem to be a straight swap - I have lost semi auto, it seems like the dimensions are very slightly different between the rocket selector plate and the original, so I am wondering if I should try to remove material to make the circled parts (image below) the same size as I am guessing that is the main issue. After reassembling, it still didn't sound as good as I had been hoping - and I realised that it will now be the shimming. The issue I have been having with the shimming, is since getting the new screws which are holding the gearbox shut tighter, the spur and sector gears are too tight from a single 0.1mm shim, so I decided to not use any shims for these gears. I'm now noticing that the spur gear is clipping the bushing for the sector gear, and possibly even the bevel gear as well. This is an issue as if I put 1 shim below the spur gear to lift it above the bushing, it then becomes difficult to spin. Do I need to buy low profile bushings to solve the bushing issue? Or is there an alternative solution which would be better (maybe tapering the edges of the gears)? And the most recent thing to have gone wrong for this build, is the positive wire on the battery side of the trigger contacts, is hanging on by a thread. It wasn't soldered very well from factory, so I'm now trying to decide whether to get the soldering iron out if I can find it, or go ahead and buy a Perun hybrid. I'm leaning towards soldering it back on, as I don't think I should try fitting an etu + mosfet until everything is working. Thanks for all the help so far, hopefully I don't encounter any more issues after resolving the above. -

Upgrading Cyma M4 - Motor/gearbox sound issues

Ben Savage replied to Ben Savage's topic in Electric Guns

I paid around £100 in December, with the intention to gut it and get a bit more practice at working on AEGs, some parts are shockingly poor, such as the gearbox screws and the body pin which holds the gearbox in which were both seemingly made of cheese from how easily the body pin deformed and how one of the screw heads snapped off before the screw was tight. It was a bit alarming that it arrived firing 450fps (especially from a UK shop) and I think that some of the cheap parts used were probably not suitable for such a strong spring and would not have lasted very long. I have a couple of Cyma 002 M4 CQBRs which have the metal receivers, and I expected the cylinders/inner barrels to be the same, but the cheaper CM603 has what appears to be a red anodised cylinder and inner barrel, whereas the more expensive CM002 has what appears to be brass cylinders and outer barrels. I found the finish on the cheap inner barrel and cylinder to be better than I had expected, but I still plan on replacing the barrel with either an XT (If 380mm is available) or ZCI (although I've seen their quality is declining), and the cylinder I had used originally until the piston head screw scratched the inside after coming free. I'm thinking of ordering some ZCI 14 teeth pistons for the current build (as the previous one worked quite well before my mistake) and having a few ready for when I decide to work on the CM002s which I plan on doing the same work to, as they already have a tooth removed which will probably be better than me attempting to remove a tooth from a Cyma piston as I don't think I would be able to do a neat enough job to be happy with. -

Upgrading Cyma M4 - Motor/gearbox sound issues

Ben Savage replied to Ben Savage's topic in Electric Guns

The stock piston had one metal tooth, and the rest were plastic so I thought it would be best to go for a full metal rack piston. -

Upgrading Cyma M4 - Motor/gearbox sound issues

Ben Savage replied to Ben Savage's topic in Electric Guns

Ah thank you, that seems to be the issue - I did as you said and it required quite a lot of force to move the piston within the gearbox, I then tried the stock piston which moved very easily, and then the remains of the previous piston could move but not quite as easily as the stock piston. I hadn't realised that the width of the piston itself could be an issue. I will see if I can do anything to make it move easily, otherwise I will buy a different piston and hope that it fits. -

Upgrading Cyma M4 - Motor/gearbox sound issues

Ben Savage replied to Ben Savage's topic in Electric Guns

Thanks for the reply, with regards to the motor, I was considering short-stroking the sector gear by a few teeth, especially as I have bought a ported cylinder, so the last few teeth of the sector gear are not causing any extra volume in the cylinder. Would short-stroking reduce the need to go for a higher TPA motor as the spring won't be being compressed as much? Also, I gave everything an inspection after the piston head detached, and anything which had even a slight bit of damage was replaced, so it doesn't seem to be any remaining damage that is causing an issue. With the piston potentially being the issue, I am thinking of trying to swap the rack on the new piston with the old one, as the previous rack didn't get damaged but I am unsure about if it is a bad idea to swap the racks on pistons by different manufacturers. Although when turning the gears manually with the piston in place it doesn't seem to be catching on any teeth so I don't know if that means it would be unlikely to be the problem. -

Hi all, I'm having some issues upgrading a Cyma M4, with the sound coming from the gearbox being quite poor. I'll give quite an in depth description of how the issue started, as it wasn't doing this from the start. I bought a Cyma CM603 for a low price in December with the intention to learn to upgrade and tinker with AEGs. It arrived firing 450fps on a 0.2g bb, so I needed to make some changes to it before I would be able to take it to a game. I initially bought the following parts: SHS High Torque Motor SHS 13:1 Gears ZCI 14 Tooth Piston XT 6 Vent POM Piston Head XT Steel Spring Guide XT M100 Spring I had to grind away part of the gearbox shell to fit the gears, as the Cyma gearbox is reinforced which prevented the spur gear from fitting properly. After doing this, I did my best attempt to shim the new gears. I attached the piston head to the piston, but forgot to use any thread lock when doing this. I then didn't have any time to continue for a couple of months, so I resumed the build this week. I found that everything looked good and ready to assemble, so I put everything back together, and it sounded like it was working great. I was achieving 20rps on a 9.6v NiMH, and it sounded quite good. I then was doing some more test firing, and suddenly a horrendous sound started happening so I stopped firing and disassembled the gun to find the screw holding the piston head had come out (Presumably due to forgetting to use any thread lock), causing a lot of damage. The piston, piston head, cylinder and spring were all damaged, so I purchased replacements. I was unable to get the same piston which I had previously used, so I bought the following replacement parts: XT 14 Tooth Piston Swiss Cheese XT 6 Vent POM Piston Head XT Metal Cylinder Head (Original plastic one wasn't damaged, but gave a poor air seal) XT M100 Spring ZCI V2 Gearbox Screws (I had a screw head snap off the original ones during assembly, so I assumed they were all low quality so replaced them all) After these parts arrived, I then reassembled the RIF and was hoping to have the same success as I had previously, but it sounded horrendous. I tried adjusting the motor height and it only sounded marginally better, so I assumed it would be the new gearbox screws making the gearbox close tighter, meaning I had to reshim. I then disassembled it and closed the gearbox back up with just the gears in, tightened the screws as they were before and tried to spin them, and they were quite tight with the new screws being used, so I decided to start reshimming (It is worth mentioning that the gears, motor pinion and piston teeth all had no signs of damage/wear). I then tried to shim it again from scratch, and after I was happy with it, I reassembled everything and test fired the gun. After reassembling it, I started test firing it and it sounded better than it did before, but it still sounded quite poor and very far away from how it did sound. I tried adjusting the motor height in both directions and I didn't really get any improvements, so I'm wondering what people think on here. I think maybe my shimming could have been done poorly this time, but before completely starting again I thought I would ask for opinions. I've attached a couple of videos of how it sounded before the piston head came off, and after my repairs. Please let me know any thoughts on what the issue could be. Any help would be appreciated, thanks. Before breaking After Breaking

-

Hello, this thread is basically to provide a log of what I'm doing for an MP5 project, and to see if anybody has any tips, or information about part compatibility. I recently acquired a boneyard G3 which was included with a bunch of other stuff, and decided to try and restore the gun to working order. From first inspection, I could see the G3 had the stock snapped, the RIS rail held on by a single screw (therefore was really wobbly), the receiver had the front part which holds the barrel snapped off, causing the barrel to bend to the left severely, and the lower receiver had a small part snapped off. There were also some other small issues which could be spotted initially. I then stripped the G3 down, to find the wires had been soldered to the motor, the wiring was not in great condition (and was also wired to large tamiya). The next part of the strip down was to open the gearbox up, which I decided to do at a later date. I made a post on here about whether it would be worth trying to replace these broken parts, or whether to build it into a new gun, and it was widely agreed upon that the condition of the G3 was basically beyond repair, especially given availability and price of parts. Because of this I was effectively left with a motor and a V2 gearbox , which I thought was in reasonable condition to use if I was to buy external parts for a different type of RIF which would have parts easier to obtain than a G3. I decided on an MP5A5 would be a nice 'project gun' and started looking for parts. I already have a TM MP5 High Cycle, and 6 mags so this decision made sense. Now I know that with what was left of the G3 it is completely pointless to try and make a gun from buying parts, when I could just buy maybe a JG or a CYMA MP5 for what would work out (much) less than this is going to come to overall, however given that I have lots of free time still as a result of the coronavirus, and an interest in learning the technical side to airsoft guns better without potentially ruining one of my working guns, I figured this would be a nice project to build. Now because I had decided on an MP5, I started briefly looking for parts, and immediately found on ebay an MP5 lower receiver in perfect condition (damage wise at least, needed a small clean when it had arrived), for just £5 which arrived nice and quickly. The listing didn't give any information about the make of the receiver, but it is identical to my TM receiver including the ASGK marking in the same position, so I'm sure this is a TM receiver. After this had arrived, I finally decided to remove the motor from the G3 lower, so I could then remove the gearbox and inspect it. The G3 was only firing on automatic, which I thought would be down to a selector plate problem, but when i looked at the side of the gearbox there just was no selector plate there, which explains the auto/auto/auto fire selector. Next up was opening the gearbox up, and it was not a pleasant sight inside. The first thing I noticed was a huge squirt of hot glue holding in a micro switch at a very bad angle, with the trigger (which had been cut down, looking very messy). There were so many problems inside of the gearbox, that the only parts that I considered to be usable again were: Gearset (Had JG markings, all but confirming the unknown manufacturer of the G3 to be JG) Piston Cylinder Spring Spring Guide Tappet Plate Anti Reversal Latch I then noticed cracks forming in the already radiused gearbox shell, and this may be an over reaction, but decided that the very small cracks were reason to scrap the gearbox shell, and replace this as well. Now that I had decided the gearbox shell would need replacing, it would have made sense to call the project off because it is essentially from no parts now that I'm building this, but I was in need of a project so I decided to continue. So ordered an E&C gearbox shell with QD spring guide, as I had heard good things about these and considered the price to be reasonable. The first thing I did when this arrived, was test that it actually screws in to the lower receiver, which it did, so the next step is to make a shopping list of parts that will continue the project, and try and get information about compatibility from people who know more than me. I also ordered a set of MP5 gearbox springs, which will be useful for the selector plate and trigger switch assembly. Parts Owned: Lower Receiver Gearbox Shell Spring Guide Gear set Piston Cylinder Main Spring Spring Set Anti Reversal Latch Shims Tappet Plate Internal Parts to buy: [Total = £41.50] V2 Cylinder Head - https://www.ak2m4.co.uk/internal-parts/cylinder-heads/ra-m4-cylinder-head-silent - £6.50 MP5 Nozzle - https://www.fire-support.co.uk/product/lonex-mp5-a4-a5-sd5-sd6-series-air-seal-jet-nozzle - £8.00 MP5 Selector plate - https://www.fire-support.co.uk/product/lonex-anti-heat-selector-plate-for-mp5-series - £9.00 MP5 Trigger - https://www.fire-support.co.uk/product/ultimate-reinforced-trigger-for-mp5-series - £8.00 V2 Switch Assembly - https://www.ak2m4.co.uk/internal-parts/trigger-switches/ra-trigger-switch-v2-red - £4.00 V2 Cut Off Lever - https://www.ak2m4.co.uk/internal-parts/cut-off-levers/ra-cut-off-lever-v2 - £3.50 V2 Safety Lever - https://www.ak2m4.co.uk/ec-safety-latch-v2?search=safety - £2.50 Inner Barrel - Included with Upper Receiver Set Hop Up Unit - Included with Upper Receiver Set Wiring - MOSFET - Perhaps GATE MERF? - Recommendations welcome External Parts to buy: [Total = £79.00] MP5 Upper Receiver set - https://www.fire-support.co.uk/product/ics-a-series-complete-upper-kit-for-mp5 - £79.00 MP5 Motor Base Plate - MP5 Collapsible Stock - MP5 Fire Selector - Hope to keep this up to date with changes that take place, and if anybody has any part recommendations, (especially for parts not yet listed) it would be great, and any feedback will be greatly appreciated as well. Photos will also be added eventually, as this begins to take shape.

-

I use NiMH for the majority of my guns, and the performance from the LiPo is without a doubt superior, but NiMH is perfectly acceptable to use provided it is working well. There is a considerable difference in rate of fire and trigger response between NiMH and LiPo, but it doesn't mean the NiMH should be not used. It might be worth testing the NiMH when fully charged to see if it performs well enough for you to be happy with it, as if it isn't good enough then there then you may as well get rid I have a few NiMH which for some unknown reason fully discharge in less than 20 shots, however I have some which have recently lasted entire days at a game without needing to be changed, just rate of fire does slow down as the day goes by. If you have a smart charger then they're very easy to charge, and again I find charging to be the biggest problem for me battery wise, as overnight they can lose a little battery but still work well usually.

-

Solved - TM Mp5 High Cycle Trigger Problem

Ben Savage replied to Ben Savage's topic in Electric Guns

Final Update: Part arrived about 12 hours ago, and after teaching myself to solder (admittedly not well), the MP5 has now been fixed (although the pesky anti reversal latch came out of place 3 times during gearbox assembly without me noticing until testing), just currently without a MOSFET, but thanks a lot for all of the advice, great to have one of my best guns working again. -

Classic Army G3 (Presumably) Broken Externals

Ben Savage replied to Ben Savage's topic in Electric Guns

I'm unsure as to which would be best, because I'm not having the best luck finding G3 parts that are in stock, and as I still don't know for sure which make it is I do not know what it is currently compatible with. I really like the looks of a G3, but if it would be way too difficult and expensive to source parts, then I would have to go in another direction. -

Hey all, Me and a friend recently acquired what we believe to be a Classic Army (EDIT: It appears to perhaps be a JG model but I am still unsure) G3 SG1 amongst a bundle of working equipment for a low price. The reason it was so cheap, is that the gun is full of (mostly) external issues, such as: Stock has snapped where the plastic main section meets the metal which holds it to the receiver (Would need replacing) Lower receiver has had where the magazine catch retaining pin is held snap on one side (Presumably would need to be replaced too) Upper receiver right hand side has had the metal part, which holds the barrel in place at the front of the receiver, break off (Would need to be replaced probably but I have the broken part, just I doubt it could be fixed easily) Parts of the cocking tube appear to have snapped off Almost every thread for a screw is stripped Fire selector does not change fire mode (Stuck in automatic) Essentially, this leaves me with just a V2 gearbox and few working components from the original G3. I'm wondering if you guys think it would be worth trying to source replacements for all of these parts, given that we still can't guarantee the manufacturer of this gun is actually Classic Army, so there could be compatibility issues down the line, or perhaps if it would be worth scrapping the idea of a G3, and taking the gearbox and maybe buying parts which could be cheaper, or easier to source for another gun using a V2 gearbox. I have thought that maybe an M4 or an MP5 could be built if the G3 is not economical to repair, as parts for those are much easier to source, or maybe even a different build entirely. I know that it would probably be cheaper to buy a new gun than build one from just a gearbox, but I would like to use it for something and see how it goes if possible. Please let me know any thoughts or ideas, thanks. Some photos to show some of the broken parts:

-

Solved - TM Mp5 High Cycle Trigger Problem

Ben Savage replied to Ben Savage's topic in Electric Guns

It’s the A5 so a V2 gearbox, don’t worry, thought I’d mentioned that already but I was sure to double check that they were for the correct gearbox. -

Solved - TM Mp5 High Cycle Trigger Problem

Ben Savage replied to Ben Savage's topic in Electric Guns

Ok thanks, ordered that and I'm hoping it works, and I didn't think about the fact that the warfet would be unlikely to fit, so I'll keep looking. -

Solved - TM Mp5 High Cycle Trigger Problem

Ben Savage replied to Ben Savage's topic in Electric Guns

So I eventually got around to taking the gearbox apart a couple of weeks ago, and found that the trigger contacts were covered in all sorts of what is presumably carbon or something like that, but the metal looked like it had slightly worn away. I reassembled the gearbox, and tested it after cleaning the carbon and checking that everything else doesn't look to be broken. Unfortunately the same problem occurs of the trigger needing to be pulled back all the way, so I'm assuming this is the result of the metal being worn down. Now I can understand the basic mechanical functions of a gearbox (gears pulling piston back, spring sending it forward to compress the air and fire through the nozzle etc) but I really don't have an understanding of the electrical side of things, so I'm wondering what the best bet is as a replacement. I've heard lots of good things about the Gate Warfet, but I believe this is outside of the gearbox, so would I need to replace the trigger system with a replacement one that is the same type, or is there a part which is dropped in instead of the stock trigger section, which completes the circuit for the gun to fire? I really don't know the electrics of airsoft guns well (a point made clearer when I put a 9.6 to test again instead of an 8.4 and I think I've managed to blow a fuse) so it would be great for any useful information as I've been struggling to find the exact details of what I'm trying to find out. -

Thanks that has done the trick, relieved it was such an easy fix.

-

Hello all, more gun problems unfortunately.... A couple of weeks ago a group of us went to a game, and in the lead up my mate's M249 had been functioning perfectly, but when we got to the game, we put the battery in (9.6V 1600mAh NiMH), and the gun would not fire. We tested with all of our batteries, before ruling these out as the problem. When the trigger is pulled, there is no sound from the gun except for the 'click' sound which is made when the trigger is pulled. The wires get warm extremely quickly, and no electrical sound is made from any part of the gun. We had an idea it could be the fuse, so after ordering a box of fuses, I then realised that I foolishly bought fuses which are too small to fit , but we managed to test these fuses still, and it did not change anything unfortunately. If anybody has any idea what can be done to fix this, it would be great, thanks.

-

Hi all, I've had the Tokyo Marui MP5 High Cycle for a few years now, but around 2 years ago before I had a break from airsoft the gun started to have some issues which I have no clue how to fix, due to my lack of technical knowledge/experience with airsoft guns. The problem is that when pulling the trigger nothing happens, until I then apply quite a lot more force which pulls the trigger back to the very limit to which it can move and only then does it fire. This makes it entirely useless for taking to games as I can't reliably fire the gun. I think the problem has something to do with trigger contacts maybe, but to be honest that is just a complete guess. Any help would be greatly appreciated, thanks.