Leaderboard

Popular Content

Showing content with the highest reputation on 02/12/20 in all areas

-

Had a crack at painting, dirtying and distressing a gun. Not quite up to @GearTech standards (he shall remain the master 😅), but I'm happy with it! Sprayed in Halfords Khaki: Then abused with dark brown washes and attacked with various things: (Need to dust off the paint chippings/sanding)3 points

-

Macks airsoft dreamers of the week thread

PopRocket123 and one other reacted to Stratton Oakmont for a topic

You’re paying for the ugliness2 points -

Its all done in the name of convenience and consistency - you can take the thing apart repeatidly without thing fallin out that shouldnt, and shim readings are going to be repeatable. Making sure that things that are not meant to move do not move - perfect fit seldom occurs in budget airsoft. And yes i am talking about decent gearboxes and nice gear sets, even most mid range gearboxes have locating pins so once again you have consistency. Checking alignment is easy, bolt the gearbox halves together, use a dowel to check bushing hole squareness. Basically if you are pressing bushings in, if they are made of plastics by pressing in you are deforming them to some degree, if they are metal you would likely be stressing the gearbox and/or not getting squareness of fit / alignment. Something has to give. If you are using bearings the big relative clearances of the race will take up the lack of squareness / alignment. TLDR - for an easy life bond your bushings in! - A perfect or slightly undersize bushing bonded in is better than interference fit from an engineering stand point with this being airsoft.2 points

-

Quote of the month already !👍 and it’s only the 2nd ! 🤣🤣1 point

-

The 'What have you just bought' Thread

Skara reacted to Cr0-Magnon for a topic

@Skara - Your fault....1 point -

Say no Luke8449 or he will shoot you between eyes! lol1 point

-

You’re not a speed softer are you? 😂 if not then welcome to the crazy place 🙌1 point

-

People pay for the ‘magic’. The polished gearbox. The perfect air seal. The fact the gun will hit bang on 350fps.... But seriously, There will be many people who don’t have a clue about how to upgrade a gun or are afraid to do it in case they cock it up. I understand why the market is there. It’s simply coz there is a demand for it. We should never ridicule anyone whose gone down that route. I’m an example. I know my way around a next generation recoil gearbox with my eyes closed. But I can’t solder to save my life (fitting a Gate Titan and doing the soldering in this case). So I asked KoA to work on one well two of my guns as I wanted to see how a professional tech would do it. I’ve got the T-Shirt. Simple as that. Will I sell those guns? Hell no! I’ll never get my investment back. But I know they rock and that’s all that matters. And looks over performance. That’s an easy one. If I can hit a speed softer between the eyes it’s all rock n roll. 😂1 point

-

Gun picture thread

EDcase reacted to MagpieTactical for a topic

1 point -

Polyswitch Instead of Fuse

Davegolf reacted to Sitting Duck for a topic

sir we are all STILL LEARNING - with every bastard issue with these bastard toy guns present yup at times these guns are bastards, bastard coated bastards1 point -

Afuk Meet up 3.0

heroshark reacted to Robert James for a topic

I dont think so. Maybe? Check their site. No bangs1 point -

Limited Amo Games....

DerDer reacted to Adolf Hamster for a topic

i'd do it simply on weight, you want to carry a 5000 round box mag you're gonna have to lug around a 10lb+ gun means you can avoid the plastic m249's as well.1 point -

Guarder P226 Black and Chrome 5 Mags

JamesAirsofterAgent reacted to MistakenMexican for a topic

Hi All, I have a TM P226 with full guarder kit and 5 mags that I want to sell. This P226 was originally bought from Heroshark many years ago (2014). From what I remember, he made two P226s, one chrome and black, one black and chrome. I bought the black and chrome off him from the zero in forum. Originally it was well used, so I ended up having to get a new Guarder body kit for it. The new body kit hasn't seen a huge amount of wear. At the time, Luke from Negative Airsoft fixed it and set it all up. It hasn't missed a beat since. The pistol runs happily on green gas. 310fps roughly. Here's a list of what's gone into it: Genuine Hogue Grips. Laylax compensator black. Guarder lower black. Guarder slide black. Guarder Barrel Chrome. Guarder funish (takedown, decock, slide stop, trigger, recoil rod and screws) Chrome. laylax tritium sights tight bore barrel and hop rubber (maple leaf) Magazines have shims and laylax gas routers. Various trigger and BBU parts have been replaced or upgraded due to wear - but I wouldn't say it's a selling point. Points to note: The slide is worn from using a holster. 1 of the screws are missing - I'm happy to replace these. barrel is worn slightly due to contact with slide. If I've missed any details that would determine the valuation, let me know1 point -

Limited Amo Games....

DerDer reacted to Adolf Hamster for a topic

indeed, but proper support guns, not an arp with a drum mag1 point -

Polyswitch Instead of Fuse

Sitting Duck reacted to emit for a topic

Thank you both, its been very educational 🙂1 point -

All valid points. Personally I've never needed to fix bushings in, maybe I've just been lucky? Granted none of my guns ever gets used so much as to cause catastrophic wear and if we were talking about someone with only one gun that they're trying to make the absolute best they can for longest life and reliability then I get it. Thing is though, where does it stop? At what point do you acquiesce to the law of diminishing returns? Most gearboxes do have locating lugs, granted but in the main they're cast from a shitty alloy to a budget and aren't great in terms of tolerances. Close enough really is good enough for the vast majority of cases in airsoft. As for pressing in bearings, yes excessive force or too tight a fit will cause stress on the gearbox shell. A cheap/badly made gearbox might crack...eventually. Really shouldn't be an issue with a decent CNC aluminium gearbox though, plus you should be able to ensure you get high quality bearings/bushings designed to fit a precision machined hole. Granted there is a potential for the bearing to go in skewed as the shell thickness isn't huge compared to the diameter of the bearings but there's just as much risk that a loose fitting bearing/bushing will be off centre if you glue it in. Anyway, as with all things - your mileage may vary. I don't think you should need to glue in bearings/bushings but that's my opinion/experience.1 point

-

Polyswitch Instead of Fuse

emit reacted to Sitting Duck for a topic

To be honest I've never really bothered to test a stock gun. Just a tweaked gun usually starts at around 11a to 17a. The Cyma motor is 27 tpa but weak ferrite, has some torque from 27tpa that keeps amps low, but moment the weak magnets go under load these ferrite motors can stall on a m110/120 spring. Due to long barrel, bit of creep, you probably only need m95/100 to hit 350fps. The gun is shooting then leave it as is, it was to get a rough idea to see if a large draw was blowing the polyfuses. As such, it seems the polyfuse is shit and a simple 25a to 30a mini fuse will be easily enough to provide protection without tripping/blowing regularly. All it was, to get a very basic benchmark, to study the amperage rising & falling requires more equipment & in the end matters little how detailed it all is for most of us. It starts at 80a at first then drops/rises etc.... If it blows a fuse, ergh it blows the fuse, end of the day we are just checking the average draw to compare against. Bit like studying the kinetic energy & bollox on joules/weights, in the end we want it near the site's limit but just under the chrono in most cases, than an Open University course in the study of BB mass & Magnus bollox. If it shoots straight, stays airborne, hits the target most times that will do with the actual scientific study crap. Gun is not drawing silly amps, so the fleabay polyfuse is shit it seems, fit the blade fuse & you are golden1 point -

You are porbably on an M100 spring, in which case your FPS / air seals are all very good I was going to say, but held my tongue... dont get hung up on measuring amp/current, unless you have very expensive test kit - as you have found - it does not show peak draw all that well etc The best test for basic kit is just do a sustained full auto burst (3 secs) and get the constant/settled amp draw. The amp draw you are reading is showing you power consumed, this is affected mostly by higher or lower effort required to turn over/cycle the gearbox. A more poweful spring, binding/tight shimming, sticky piston, gear meshing, etc, will all increase effort. There are so many variables, but get a base reading. Your gears should have a very small amount of vertical play, clearance for lube and a tiny amount of heat expansion. Talking a 3 thou 0.003" or 0.75mm. Provided your motor height is in the ball park, you may find you can perfect it by doing the basic amp draw test above, adjust the height like 1/8 turn, re-test etc to get the lowest reading. You should not be more than 1/4 turn either way than your start point really if mesh is set correctly. You can use your base reading against lots of little tweaks - shimming / piston rails / gear setup etc PS make sure your battery is always in the same state of charge for apples to apples test results!1 point

-

Afuk Meet up 3.0

Tackle reacted to Jaylordofwaargh for a topic

Yes, I went and checked your content count. It appears I have some thread spamming to do1 point -

1 point

-

Is there a limit to how new a member? I'd love to get to know a few of you and I'm only 10 miles or so from Newbury. I've been looking for an excuse to get my arse over there and it would be a good way destress after a house move.1 point

-

Bushes and Bearings

Lozart reacted to Sitting Duck for a topic

To clarify the advice given.... The question was asked how to stop the bushings falling out ??? I gave the response to epoxy them in & note a cheap Poundland epoxy rather than JB Weld or something A light smear & I have been able to remove a couple of epoxied bushings easily by a gentle tap - though there have been horror stories of cases cracking/chipping when trying to remove an epoxied bushing (must have used industrial strength by the boat load) The instance when a 13:1 spur was too thick to shim & had to place a bearing on top of spur thus had to remove a bushing & replace with 8mm bearing instead The expoxy suggested is hardly industrial strength & if a light blow failed to shift it then place the casing in warm soapy water will assist its removal If bearings/bushings or whatever are loose enough to fall out then have fun trying to shim that box easily if they do not hold in place whilst pushing on axles etc... Like correcting AoE, how much & what you use, ptfe for cylinder heads... what wiring, mosfet/ECU system you use, your preferred motor/gear setup along with your own personal rof, bb weight/mass - and fuck knows what else like brand of toy gun etc... It is ALL down to your personal choice/preferences like nigh on most things in airsoft/life What I do, is not gospel nor set in stone as I have altered & changed a number of things I do now compared to say 6 years ago or even a few years ago, plus each box presents different issues along with the various components that work/don't work as they should If the replacement bearings/bushing fit snuggly there would be no real need to fix them in place however as the old ones are removed, sometimes they needed a little coaxing to come out, that in turn will add a little wear that even the exact same replacements may not fit quite as snug as the originals did from the factory/sweat shop, so what to do if faced with loose bushings ??? (and the term loose is open to interpretation - if it is as loose as fuck then you need to try other bushings or something before maybe looking for a new/less worn shell for example or some method to ensure centred better before trying to affix them) But loose bushings will make it a little awkward to shim up imho and numerous people decide to epoxy them in if they are not quite a snug fit others are dead set against it & that is fine it is their call/gun in the end Same as epoxy-ing a steel rack in the piston, by default some pistons already come affixed/epoxied sometimes they are affixed poorly, other times the rack comes out very easily - even quite loose in some so when you might removed 2nd tooth you have the choice to refit or affix/epoxy the rack in like bushings (call it peace of mind, call it what you will, but your call all the same) The epoxy was a cheap mild glue & method to affix loose bushings & if done correctly can be removed OK (an old chunky spur gear (top side), comes in handy to push in the bushings and to assist in removing old ones) To each their own as they say, but I epoxy them in and have been able to remove them without damage (when required) I do not consider myself as the divine word on stuff, merely what stuff I do (at present) and my own methods are constantly being reviewed & updated as I go though I've been expoying stuff in where required for quite a while - my own personal choice btw if bearings/bushing fit in all snuggly, then I probably wouldn't need to epoxy them invariably I find in many cases they can fit in a little too easily & so I will add a smidge to hold them in place (just so they stay put for shimming and not lift out still attached to gears when opening gearbox shell etc...) Your gun/box - your choice as they say1 point -

Fixed link: https://www.legislation.gov.uk/uksi/2020/1374/made1 point

-

Gun picture thread

GeorgePlaysAirsoft reacted to SeniorSpaz87 for a topic

1 point -

Cyma Ak47 Stock

Nick G reacted to Adolf Hamster for a topic

It might not be the spring, air seal would be my first port of call.1 point -

Guns That Aren't as Popular as They Should Be....

PopRocket123 reacted to Adolf Hamster for a topic

Also nimh I swear thats just a way of getting out of warranty claims "oh you used a lipo/modified the gun, thats not fair use"1 point -

I'd say 'Excellent job on that' And I do like my things worn 😁1 point

-

Gun picture thread

L3wisD reacted to PopRocket123 for a topic

Looks good and the wear is all in the right places. So often you see weathering jobs and there are scratches and wear where it makes not sense.1 point -

Daytonagun M240b / Gpmg Build - Ongoing Development

GeorgePlaysAirsoft reacted to Dirtyfilthyscoundrel for a topic

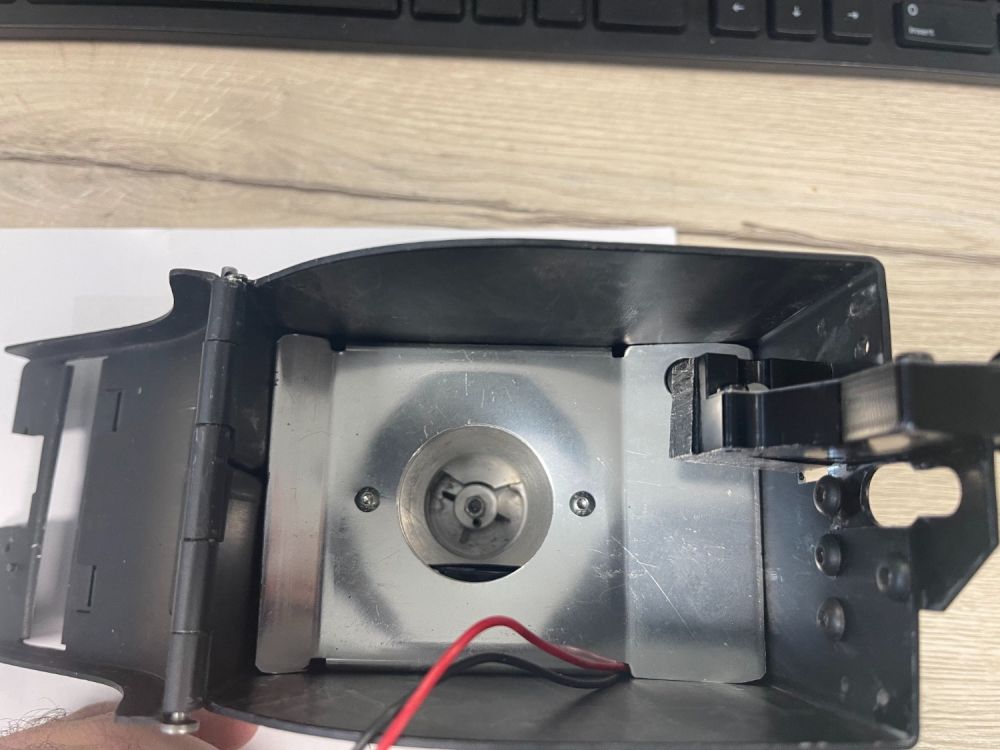

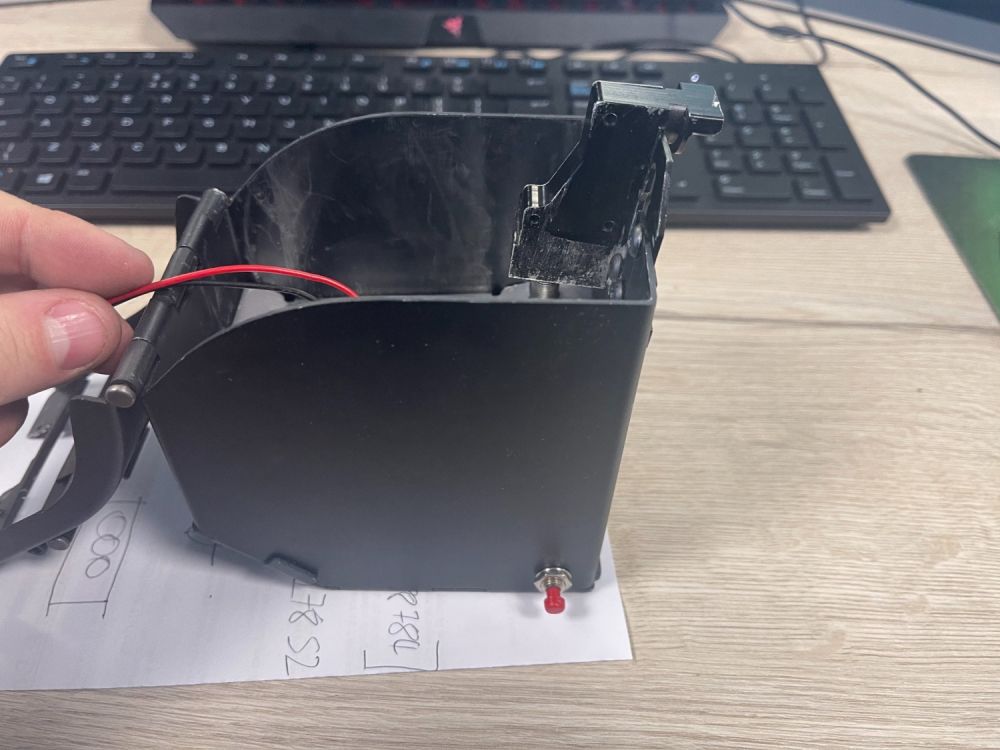

Finished the wiring and the winding mechanism for the mag today. The mag was part done before I bought the gun, using a real steel 50rd GPMG belt holder, the bracket had been mounted to the box. I've drilled a hole to fit a push switch to engage the mechanism, soldered in connections from the motor and then to the wires out. Have a stand alone 9v battery box with an on off switch located in the gas tube, I can se it to permanent wind, and has a rubber band style clutch system 😂 bracket was filed and ground down to line up so it'll feed . Firing test tomorrow1 point -

Daytonagun M240b / Gpmg Build - Ongoing Development

Dirtyfilthyscoundrel reacted to SeniorSpaz87 for a topic

As a fan of Daytonas (think I have now owned 6 plus one pre-Daytona) they do require a lot of work and love. Remember to lube. Ima avoid the usual Daytona innuendos here but if you arent filthy by the end of a break-in session you arent using enough lube. Never done a 240 but I did do a 249 and a m60. Enjoy.1 point -

1 point

-

Hi @Barry08 Welcome to the mad house.🤪 Try and checkout @GAMBLE's website( utube) channel. He has really good info and tips aimed at helping you find your way. That's gotta be worth a like. Eh? Eh? Lol Regards1 point

-

1 point

-

I can see where you are coming from, but that’s a lot of fire to chill down that much. Playing at this time of year you also wouldn’t want a hard bucking as the ambient temp alone will make it so hard it will reduce friction/backspin. Also factor in the bucking has to take the nozzle fairly deeply and aggressively. 50-60D is fine for most sub DMR FPS. Silicone is more temperature stable but they can be mechanically weaker than rubber.1 point

-

Bushes and Bearings

Sitting Duck reacted to Shamal for a topic

I think they will come out very easily. It's just to stop them rotating. It's a very thin film of 'glue'. Bit like loctite really holds firm but not immovable when needs be.👍 Regards1 point -

Bushes and Bearings

Sitting Duck reacted to Davegolf for a topic

Bearings offer less rotating resistance, but ideally need the gear axles to be a tight fit into the inner race. Ideally suited to low load / high RPM. - Spastic ROF builds Bushings are a static item, the gear axle rotates in the bushing with a clearance for lubrication. A Moly type grease is best for this application. Ideally suited to higher loadings. It is for this reason that bushings should be bonded into place, so they do not in turn rotate in the gearbox shell. I use Loctite 270 for this purpose, if you need to remove them for whatever reason this easily done with the aid of a heatgun.1 point -

Unfortunately the airsoft obsession now is to the have the best most powerful gun at 99.999% site limit. Joule creep just allows the idiots and cheats to deliberately break those limits and then claim ignorance if caught. If sites can't police J limits, I'd suggest chrono full auto's on 0.3/0.32 and snipers/dmr on 0.40+. That would negate most of the crazy joule creep builds and improve safety.1 point

-

Reducing FPS

GeneralJock reacted to Groot for a topic

Quote Yeah, I'm realising there is a big branding thing going on with fewer manufacturers than sellers. From your reply you don't think clipping the spring's a bad idea? I am sure I will work out where to find a generic replacement. Thanks for the advice. Nothing wrong with clipping a few coils to drop 5 - 10 FPS. Clipping to drop 60 or so, could result in a short spring. It will work but you will probably end up with a nicer pull with a weaker spring. Rather than pulling a shortened harder one. You also have the potential of joule creep to worry about. So I would do the following. * First step is get access to a chrono. * Do any upgrades to the hop and ptfe the unit for airseal. * Take the bolt apart, check the quality of the oring. Replace and lube as necessary. * Decide on what weight ammo it going to be used. * Set the hop You are now ready to chrono and work out if you need to remove a few coils or if a new spring is a better option.1 point -

Reducing FPS

GeneralJock reacted to Chev Chelios for a topic

I left a TM VSR10 cocked for a week, I cant remember how much power it lost but it was enough for me to replace the spring.1 point -

Reducing FPS

GeneralJock reacted to Groot for a topic

Most sniper rifles are much of a muchness and to be fair that ASG is probably a copy of something. The trick is to find out of what and then either clip the spring or get a lower power spring to suit. While you are hunting to find out what it is a clone of. I would recommend you look at what cheap upgrades you can do to the hop to improve consistency. Just replacing the bucking for under £10 can make a huge difference. Every cheap sniper i have ever seen tends to be pretty terrible in that department.1 point -

Misheard Phrases.

John_W reacted to MagpieTactical for a topic

Not misheard, but i used to work in I. T. on a contract supporting the Met. Police. It was amazing how many of them didn't know the phonetic alphabet. I loved fucking with them when spelling things by saying things like P for pneumonia, G for gnome, x for xylophone etc. I could hear their brains exploding down the phone line.1 point -

1 point

-

What really gets my goat is those dickheads that rant about esspresso, when it's actually spelt espresso 😜1 point

-

Misheard Phrases.

John_W reacted to Cr0-Magnon for a topic

One of the kids at my Nephews nursery would say "please subscribe" rather than bye. Transpires it's because he watches so many YouTube videos he genuinely thought that's how you ended a conversation.1 point -

THIS ADVERT IS 'UNCOMPLETED' - THIS MEANS THE ADVERTISER HASN'T BUMPED THIS LISTING, BUT IT COULD STILL BE WORTH CONTACTING THEM.

- For sale

- As new

Hi guys, All guns and parts shipped from France, all price are PayPal & shipping out. [u]WANTED/TRADE :[/u] _ [u]Crosse UBR (copy) for GBB-R[/u]; Let's go [center][b]------------REPLICAS/UPPER------------[/b][/center] _ [b]M16A4 G&G,[/b] M16A4 G&G Proline (blowback, metal body, etc.), 360fps @ 0.20, sold with original box and packaging, [u]200€[/u] [url="https://www.casimages.com/i/5TvQIb-IMG-20200111-192521.jpg.html"][img]https://nsm09.casimages.com/img/2020/01/11//mini_5TvQIb-IMG-20200111-192521.jpg[/img][/url] [url="https://www.casimages.com/i/6TvQIb-IMG-20200111-192655.jpg.html"][img]https://nsm09.casimages.com/img/2020/01/11//mini_6TvQIb-IMG-20200111-192655.jpg[/img][/url] [url="https://www.casimages.com/i/7TvQIb-IMG-20200111-192722.jpg.html"][img]https://nsm09.casimages.com/img/2020/01/11//mini_7TvQIb-IMG-20200111-192722.jpg[/img][/url] [url="https://www.casimages.com/i/8TvQIb-IMG-20200111-192802.jpg.html"][img]https://nsm09.casimages.com/img/2020/01/11//mini_8TvQIb-IMG-20200111-192802.jpg[/img][/url] [center][b]------------GEAR------------[/b][/center] [center][b]------------PTW/CTW/FCC ZONE-----------[/b][/center] _ [b]Uppers HK416 for PTW,[/b], Fully working HK416 uppers for PTW, sold with no external parts or internal, no flash-hider. One with markings : 250€, lone pantjobed, 230€ Markings : [url="https://www.casimages.com/i/7SsHKb-IMG-20201123-213118.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_7SsHKb-IMG-20201123-213118.jpg[/img][/url] [url="https://www.casimages.com/i/4SsHKb-IMG-20201123-213106.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_4SsHKb-IMG-20201123-213106.jpg[/img][/url] [url="https://www.casimages.com/i/BSsHKb-IMG-20201123-213125.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_BSsHKb-IMG-20201123-213125.jpg[/img][/url] Paintjobed : [url="https://www.casimages.com/i/JSsHKb-IMG-20201123-213745.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_JSsHKb-IMG-20201123-213745.jpg[/img][/url] [url="https://www.casimages.com/i/GSsHKb-IMG-20201123-213739.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_GSsHKb-IMG-20201123-213739.jpg[/img][/url] [url="https://www.casimages.com/i/MSsHKb-IMG-20201123-213753.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_MSsHKb-IMG-20201123-213753.jpg[/img][/url] _ [b]Grip MOE FCC noir pour PTW[/b], TAN sold, noir avaliable, sold with screws and end plate, [u]20€[/u] [url="https://www.casimages.com/i/SSsHKb-IMG-20201123-213845.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_SSsHKb-IMG-20201123-213845.jpg[/img][/url] _ [b]Grip A1 Systema pour PTW[/b], Sold with end plate and screws, [u]15€/unité[/u] (4 avaliable, closed cage avaliable, just ask for it) _ [b]Carry Handle Systema[/b], The real steel model, [u]20€[/u] [url="https://www.casimages.com/i/bTsHKb-IMG-20201123-214111.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_bTsHKb-IMG-20201123-214111.jpg[/img][/url] _ [b]Lower DTW + stock tube DTW[/b], Broken parts (see photos), [u]25€[/u] [url="https://www.casimages.com/i/eTsHKb-IMG-20201123-214122.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_eTsHKb-IMG-20201123-214122.jpg[/img][/url] [url="https://www.casimages.com/i/hTsHKb-IMG-20201123-214127.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_hTsHKb-IMG-20201123-214127.jpg[/img][/url] [center][b]------------ACCESSOIRES/PIÈCES DÉTACHÉES------------[/b][/center] _ [b]Rail SPR Balystik 12.5"[/b], The black one, MK18 already sold (approx 12.5"), working on PTW, [u]30€[/u] [url="https://www.casimages.com/i/2ecfKb-IMG-20200730-143258.jpg.html"][img]https://nsm09.casimages.com/img/2020/08/10//mini_2ecfKb-IMG-20200730-143258.jpg[/img][/url] _ [b]Complete internal HK416 WE[/b], Coming from a HK416 lower (trigger box, selector, bolt catch, ...) fully working, [u]50€[/u] _ [b]Culasse HK416 WE[/b], Fully working, [u]40€[/u] _ [b]Mags MP7 AEP[/b], 2 x hi cap (long) et 2 x low cap (short), MAG brand for low cap, [u]20€[/u] [url="https://www.casimages.com/i/YSsHKb-IMG-20201123-213940.jpg.html"][img]https://nsm09.casimages.com/img/2020/11/23//mini_YSsHKb-IMG-20201123-213940.jpg[/img][/url] Thanks for reading me. DinDon£200

0 points

.thumb.jpg.bb0c795e1648fc93204ba7529bca214b.jpg)